Outsourcing metal profiling is a solution to many challenges. One of the key benefits is that manufacturers can avoid the need to invest in and maintain equipment to keep up with ever-improving speed and quality standards. The downside to outsourcing can be unpredictable lead times. When demand spikes, it usually affects various parts of the supply chain in multiple industries, with profiling lead times suddenly becoming a problem.

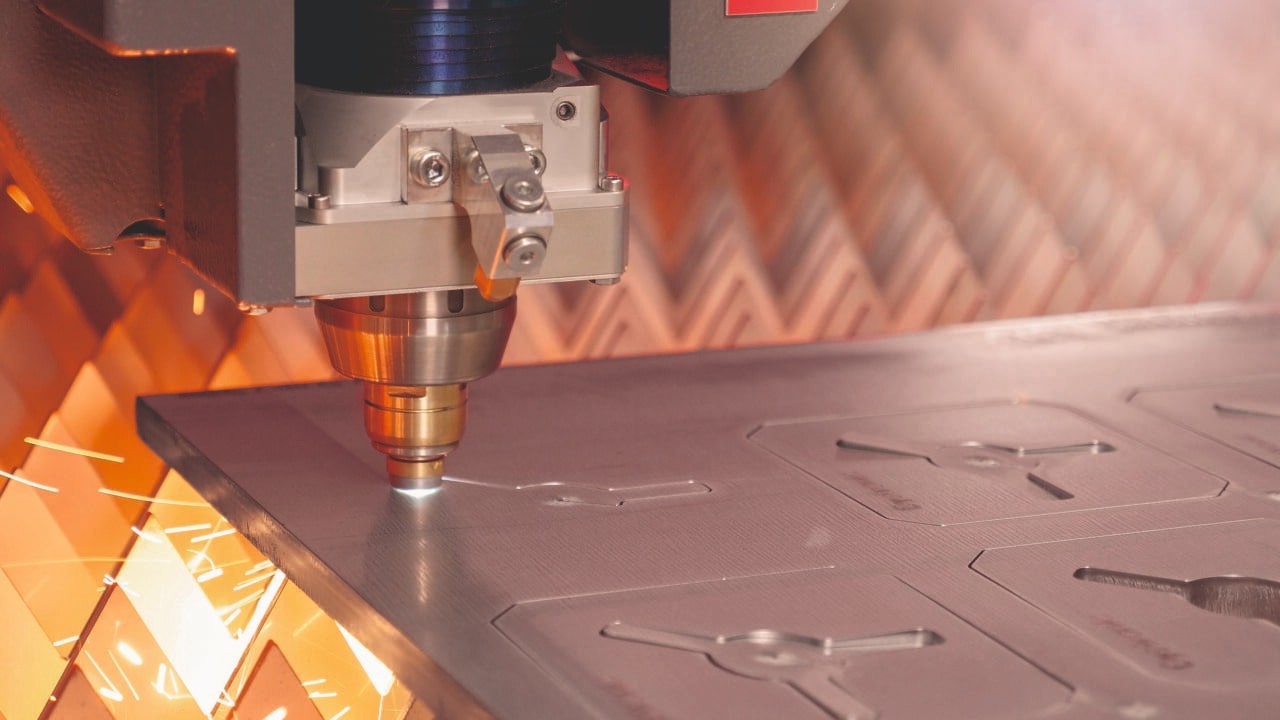

To maintain its unrivalled profiling service, Charles Day maintain a continuous program of investment. The latest addition to the Sheffield-based cutting service brings with it a powerful capacity boost with a new – UK first – 20kW fibre laser delivering a 40% boost in productivity. Charles Day can now offer customers an even better laser cutting service.

Improved cutting capacity

Improving cutting capacity with the addition of a 20kW ByStar fibre laser means customers benefit from even shorter lead times and lower cost per part. Investment in the latest cutting technology opens more opportunities for customers to outsource a greater range of projects:

- Large parts without long lead times

- Stable lead times during demand spikes

- Competitive price per part

- Consistent and improved cut quality.

While lead times and fluctuating material costs are a key concern for any project, the risk of overlooking part quality cannot be ignored. Without accuracy, costs increase, and reputation suffers. Parts have to be correct and on time, every time. Charles Day continue to invest in quality laser cutting to ensure that increased productivity is not at the detriment of cut quality.

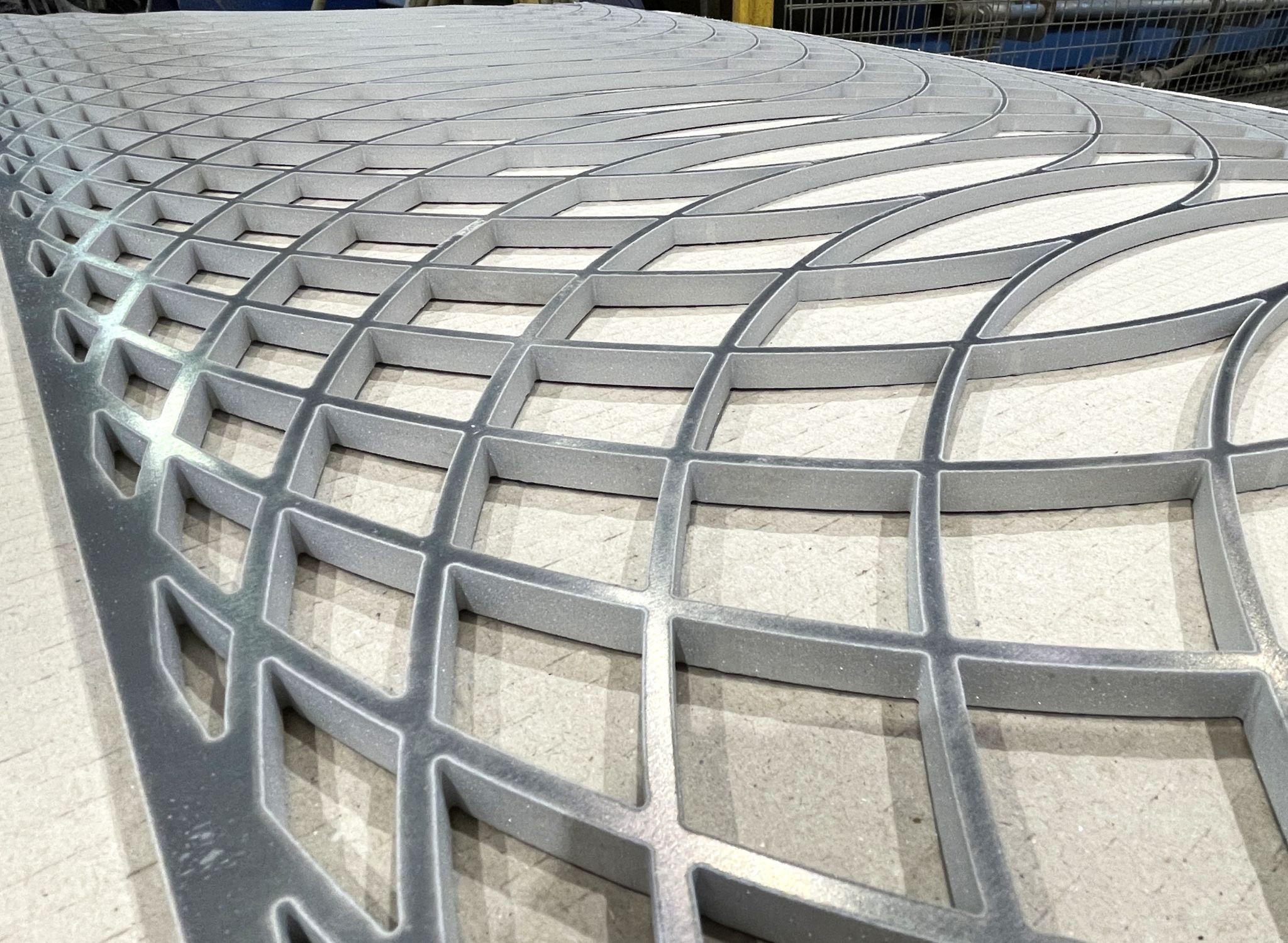

The new 20kW laser is designed to produce the highest levels of productivity whilst maintaining accuracy. Demanding applications, such as high complexity or high volume jobs, benefit from precision, Swiss made cutting heads. Quality machining transfers across multiple materials, including ferrous and non-ferrous metals such as steel, aluminum, stainless steel, copper, brass and bronze, and sheet thicknesses up to 50mm.

Maximum cutting thickness:

- Steel – 50mm

- Stainless steel – 50mm

- Aluminum – 40mm

- Brass – 20mm

- Copper 20mm.

Charles Day laser cutting capabilities have been given a boost with this latest addition, taking the laser cutting machine count to 5 with a further 2 lasers at Sheffield sister site, The Laser Cutting Co.

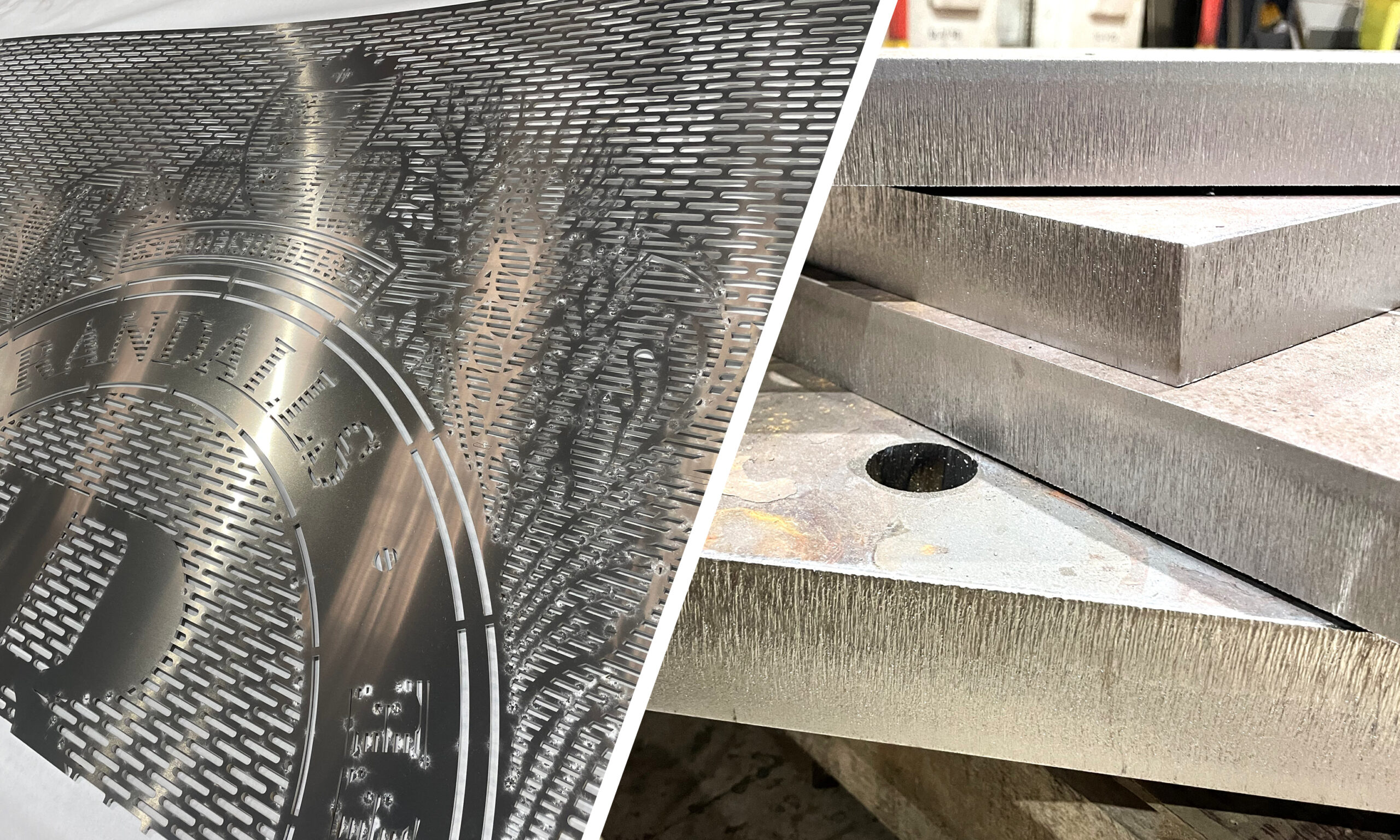

In addition to an impressive suite of laser cutting machines, Charles Day offer a comprehensive range of cutting technologies including tube laser cutting, waterjet cutting and flame cutting. A true, one-stop profiling shop, from design and materials to cutting and weld prep, additional services mean an order can be delivered complete, fully weld prepped and ready for assembly.

Additional profiling services include:

- Waterjet cutting

- Flame cutting

- Plasma cutting

- Profile bending and pressing

- Bevels and countersinks

- Shot blasting

- Deburring and Vibra-deburring

- Laser engraving.

Get a no-obligation quote for your next project and see how much you can save: