Offering Professional Shot Blasting Services

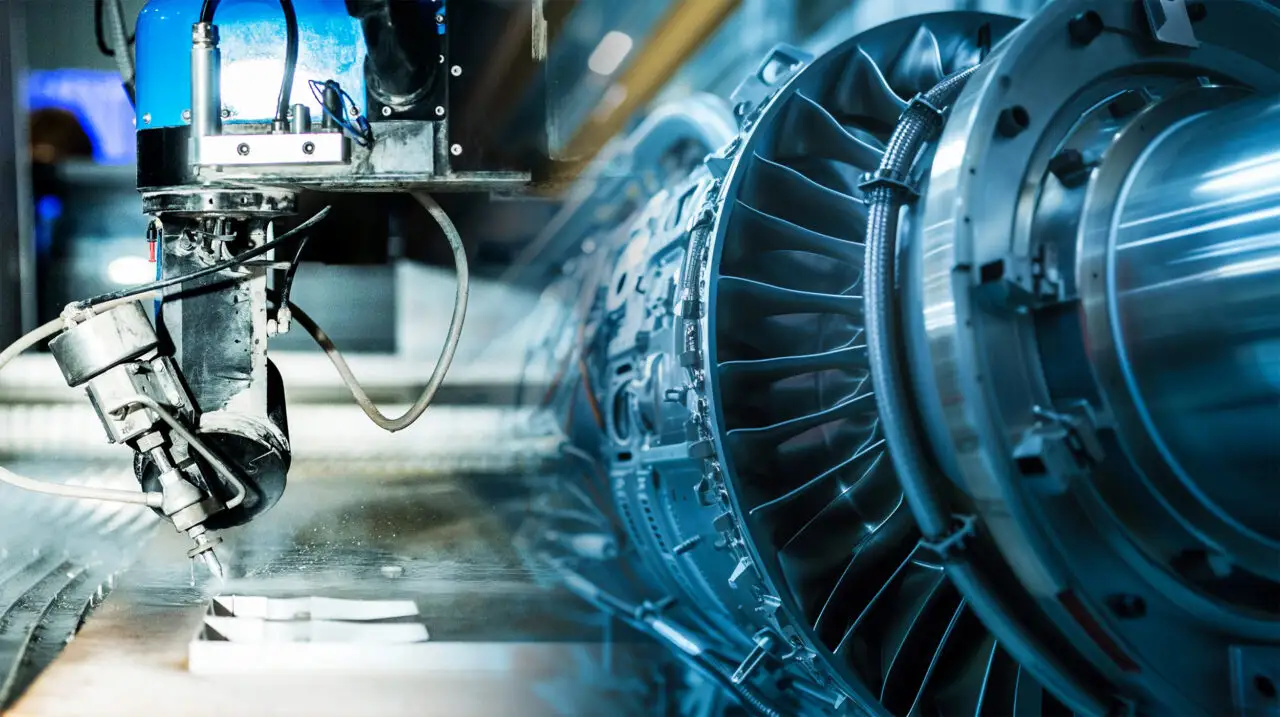

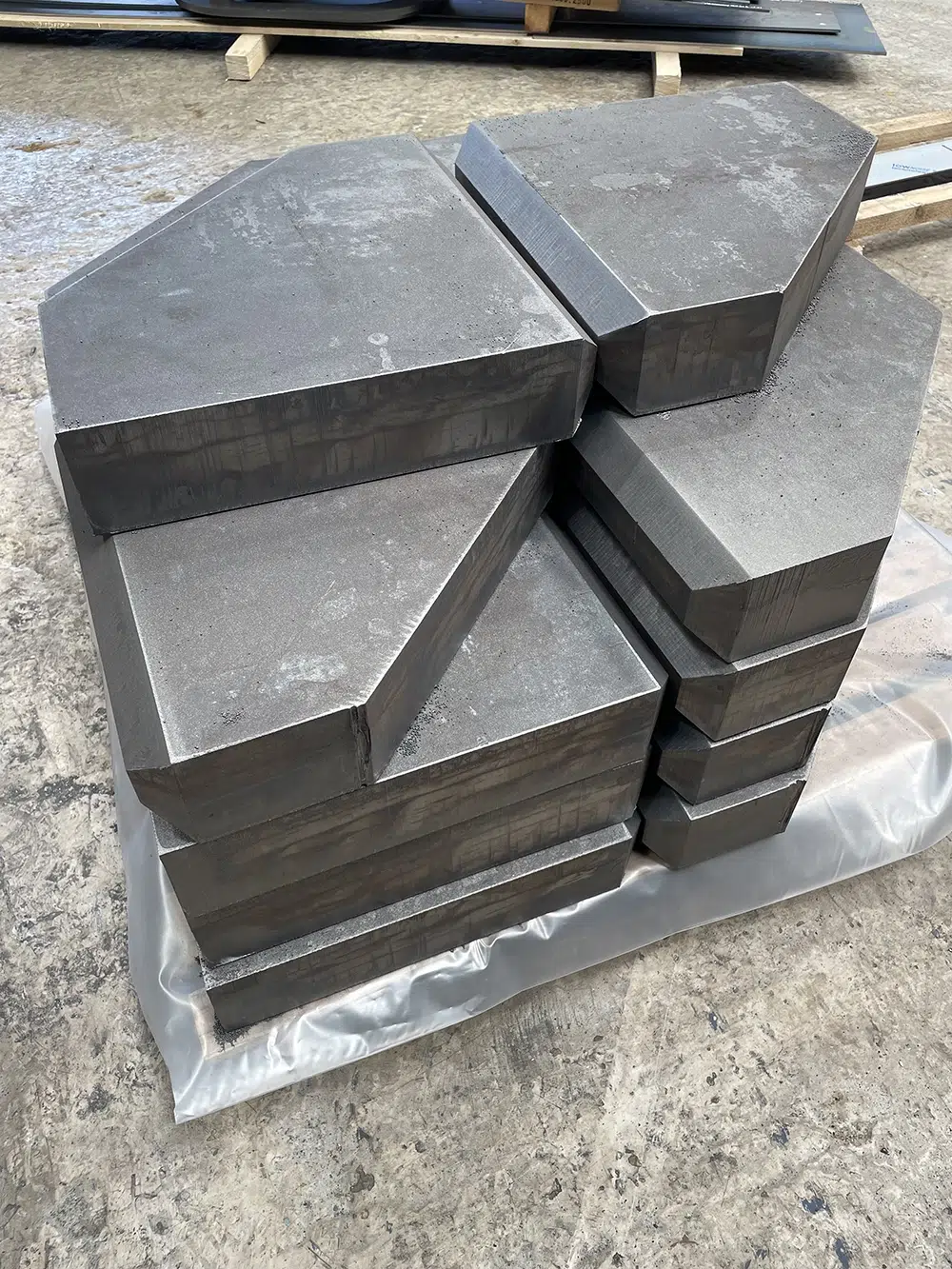

With over 4 decades of industry experience, our team of professionals are able to advise on how best to improve your efficiencies; offering in-house shot blasting capabilities available on-site, as well as via our trusted partner network. Charles Day is proud to offer industrial shot blasting services to finish oversized parts; ensuring they are fully prepared and ready for your next chosen stage of production.

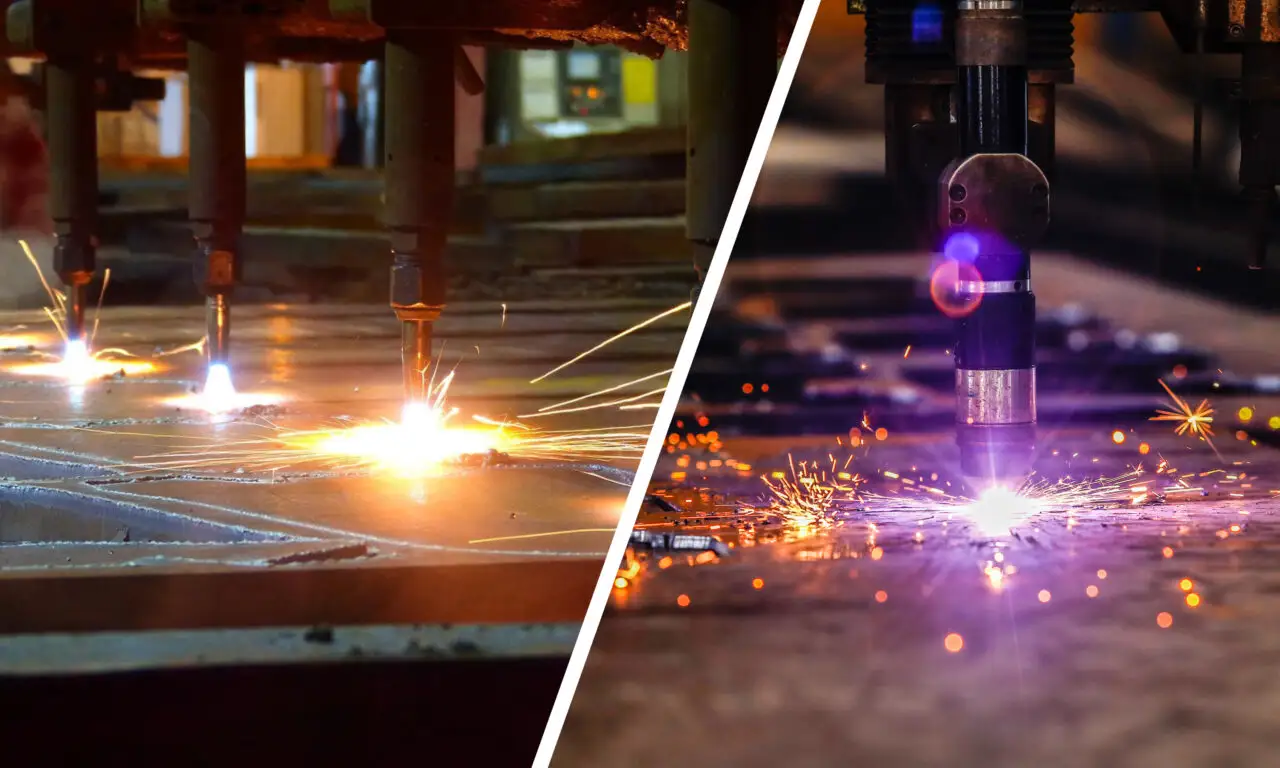

A mechanical metal cleaning process most commonly used to remove oxides and debris from the surface of a material, shot blasting hosts a range of benefits, and can be utilised to matt, descale, and eliminate residual stresses in casting, forging and welding; different sized and hardness of particle are used to produce a range of surface profile finishes and improved bonding.

Innovative Shot Blasting Capabilities for a Plethora of Applications

We understand that proper surface preparation is vital for the success and longevity of any subsequent coating or treatment. Our experts are skilled in assessing the specific requirements of your project and selecting the appropriate industrial shot blasting parameters to achieve the desired surface profile.

Depending on your unique requirements, size of your parts, and desired finish, we may offer our in-house shot blasting services, or refer your parts to our trusted partner network; no matter what, we always endeavour to satisfy even the most complex of projects.

Benefits of Shot Blasting

Commonly used in construction, automotive, aerospace, and manufacturing, industries, shot blasting has a plethora of benefits, some include:

- Removes rust

- Cleans surfaces

- Prepares parts for coatings

- Improved surface finish

- Stress relief and strengthening

- Increased productivity

- Environmentally friendly

- Cost-effective

Contact our experienced sales team

Let Charles Day help lower your costs.

Environmentally Friendly Shot Blasting by Charles Day

Considered to be an environmentally conscious alternative to traditional surface preparation methods such as sandblasting and chemical stripping, shot blasting typically generates less waste, and does not require any harmful and non-eco-friendly chemicals.

At Charles Day, we endeavour to provide an environmentally friendly alternative to metal profiling services, and aim to reduce our environmental footprint wherever possible. For our on-site shot blasting services, we always ensure that all shot particles are recycled back into the system automatically to avoid unnecessary waste.

Why Choose Charles Day for Shot Blasting?

Versatile Capability

With an extensive range of state-of-the-art machinery, unrivalled tooling libraries, and capable of pressing parts up to 3100mm in house, and 400mm+ via our partner network, you can trust Charles Day for stress-free procurement on even the most complex projects.

24-Hour ‘Lights Out’ Production

Offering some of the most efficient lead times in the industry, our series of laser cutting machines are operational 24 hours a day to ensure that your quality parts are procured on time.

One Stop Shop

From sourcing your materials at cost-effective prices, cutting and bending, through to prompt delivery, we streamline your procurement to make your project simple.

Extensive Partner Network

For complex, heavy-duty, and challenging projects, we work closely alongside our trusted and extensive network of partner suppliers to secure the very best reliability and provide the highest levels of quality on even the most demanding of projects.

Quality Assurance

Quality. Accuracy. Compliance.

From drawing to delivery, Charles Day take pride in delivering quality profile cutting services to boost downstream efficiency and profitability.

Factory production controls comply with construction product regulation BS EN 1090 EXC4 for intricate cutting of construction and nuclear regulation profiles.

Certified to BS EN ISO 9001:2015 for all profiling requirements.