Laser Cutting Tolerances at Charles Day

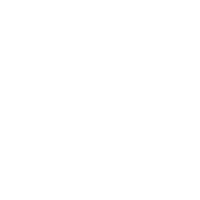

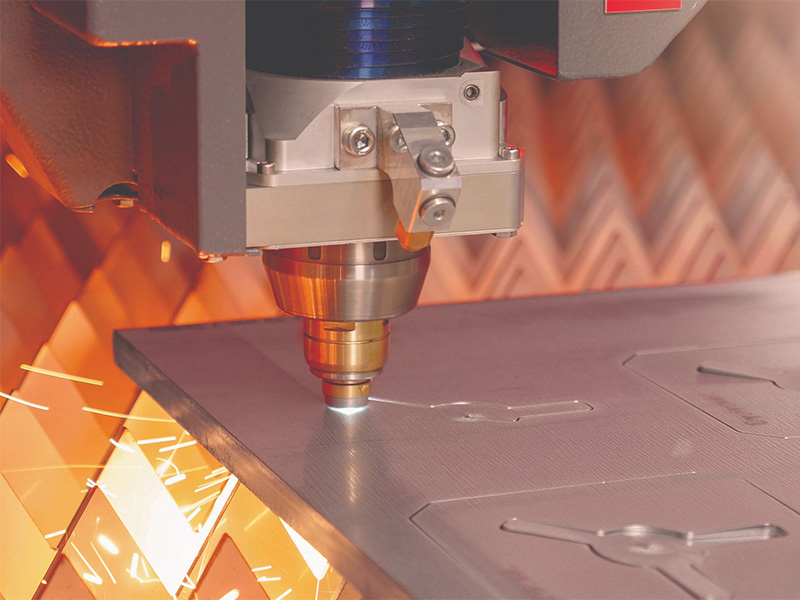

Here at Charles Day, our 40+ years of experience and industry expertise inform all of our professional metal profiling services. We understand that precision is of paramount importance to our clients, especially when it comes to laser cut parts, which is why we endeavour to provide all of the necessary and most accurate information regarding our laser cutting tolerances

Rectangular

For rectangular laser cut steel plates, where length L, is defined as the greater of the two dimensions, tolerances on length and width shall be as given in Table 1.

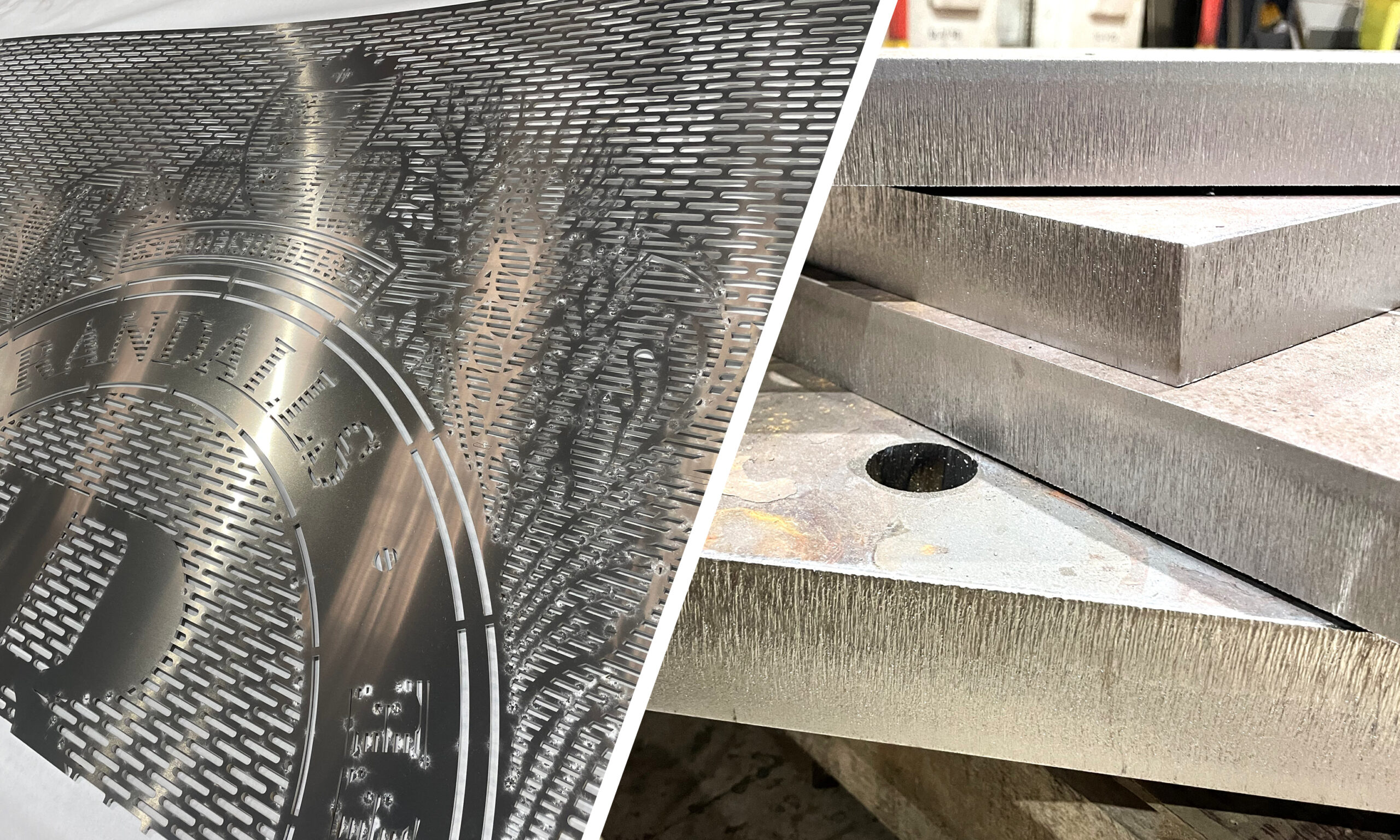

Non-rectangular

For non-rectangular laser cut steel plates, because of the difficulty in defining length and width for non-standard shapes, tolerances will be as given in Table 1, where length L shall be assumed to be the maximum dimension of the part in question.

Circles and Rings

For laser cut steel circles and rings, length L will be understood to be the outside diameter of the part in question and tolerances will be as given in Table 1.

Table 1. – Length and Width Tolerance for Laser Cut Steel Plates

Material Thickness |

< 500mm |

500mm to < 1500mm |

1500mm to < 3000mm |

3000mm and over |

|---|---|---|---|---|

|

up to 1.0mm

|

+/-0.12mm

|

+/-0.12mm

|

+/-0.12mm

|

+/-0.12mm

|

|

Over 1.0mm to 3.0mm

|

+/-0.15mm

|

+/-0.15mm

|

+/-0.15mm

|

+/-0.15mm

|

|

Over 3.0mm to 6.0mm

|

+/-0.20mm

|

+/-0.20mm

|

+/-0.20mm

|

+/-0.20mm

|

|

Over 6.0mm to 25mm

|

+/-0.25mm

|

+/-0.25mm

|

+/-0.25mm

|

+/-0.25mm

|

|

Over 25mm to 50mm

|

+/-0.50mm

|

+/-0.50mm

|

+/-0.50mm

|

+/-0.50mm

|

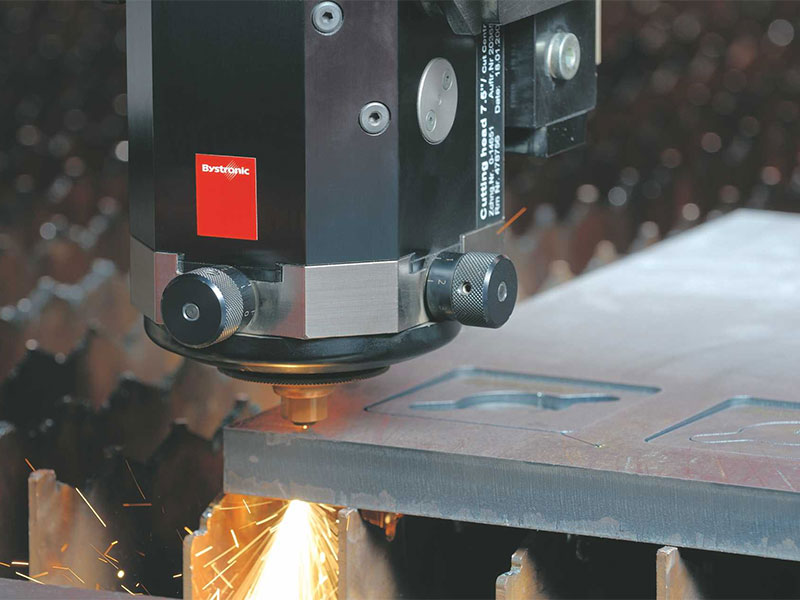

Steel Plate Thickness Tolerance

Our laser cutting services offer steel plate thickness tolerances in strict accordance with BS EN 10051:2010. This internationally recognised standard ensures that our cutting processes meet the most stringent requirements, resulting in accurate and consistent cuts for various materials. At Charles Day, our state-of-the-art laser cutting technology and meticulous attention to detail guarantee that your projects will be executed with utmost precision and adherence to the specified thickness tolerances. With our commitment to excellence, you can trust us to deliver laser cut parts that meet and exceed your expectations.

Steel Plate Flatness Tolerance

At Charles Day, we take quality and precision seriously, which is why we adhere to the strict guidelines set forth by BS EN 10051:2010 for steel plate flatness tolerances. As a customer-focused organisation, we understand the critical importance of flatness in the final product, and our expert laser cutting technology combined with skilled craftsmanship ensures that we achieve flatness tolerances in line with the specified standards.

By following BBS EN 10051:2010, we guarantee that our laser cutting services produce flat components that meet the highest level of accuracy and consistency; ensuring that your projects will be executed with the utmost precision and quality, meeting your exact requirements and expectations.

Discover Our Range of Specialist Profiling Services

Quality Assurance

Quality. Accuracy. Compliance.

From drawing to delivery, Charles Day take pride in delivering quality profile cutting services to boost downstream efficiency and profitability.

Factory production controls comply with construction product regulation BS EN 1090 EXC4 for intricate cutting of construction and nuclear regulation profiles.

Certified to BS EN ISO 9001:2015 for all profiling requirements.