Introducing Our Revolutionary New Investment –

the Waterjet Sweden BevelJet 60

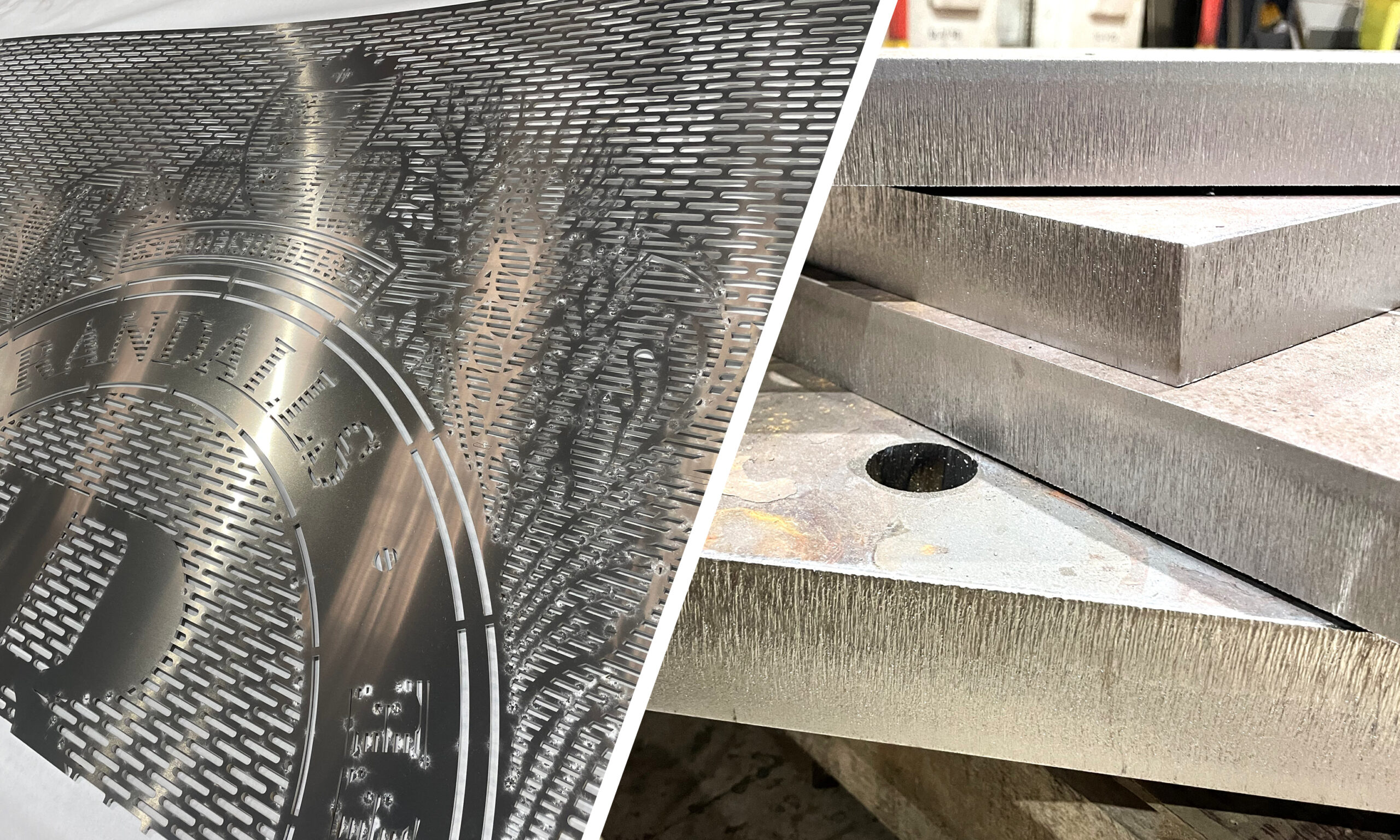

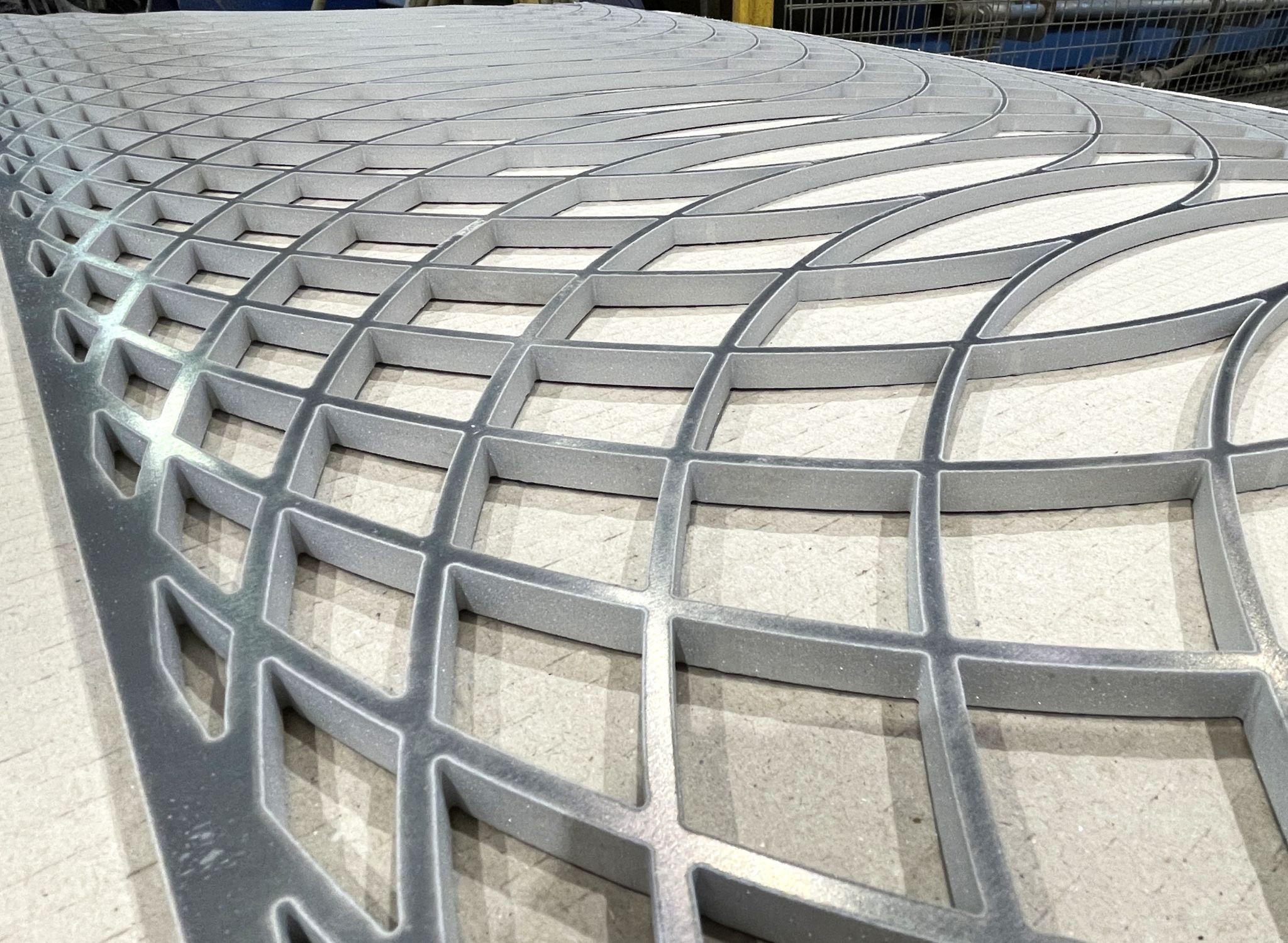

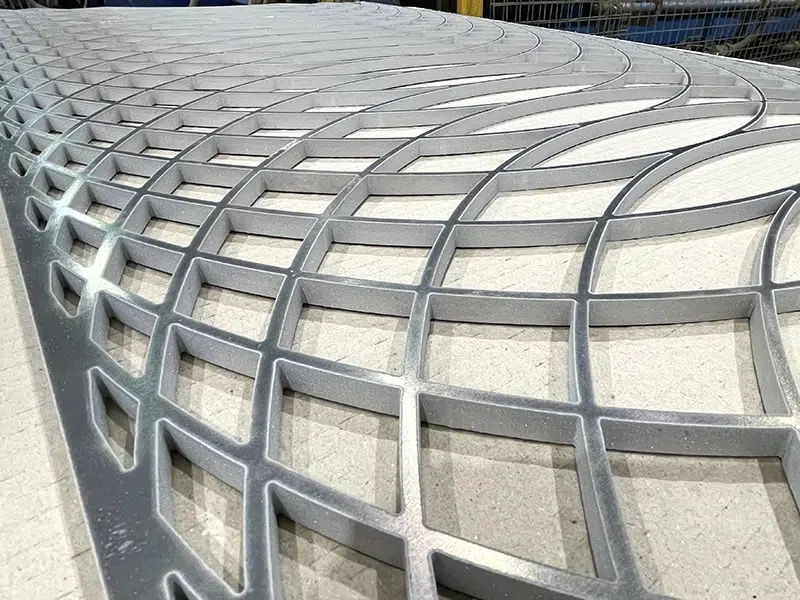

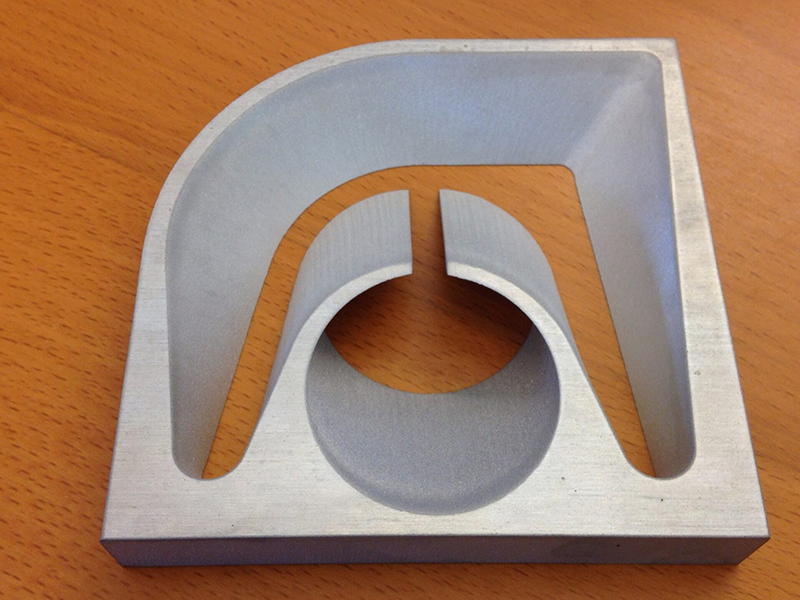

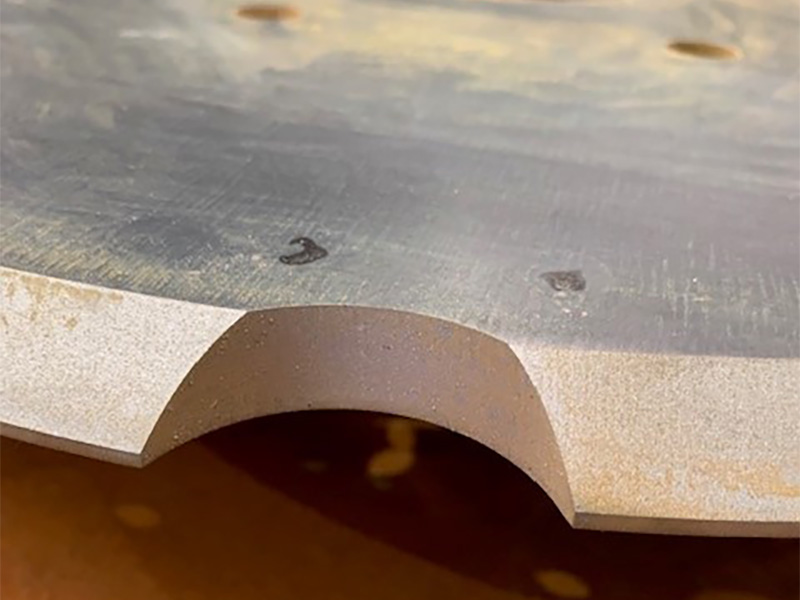

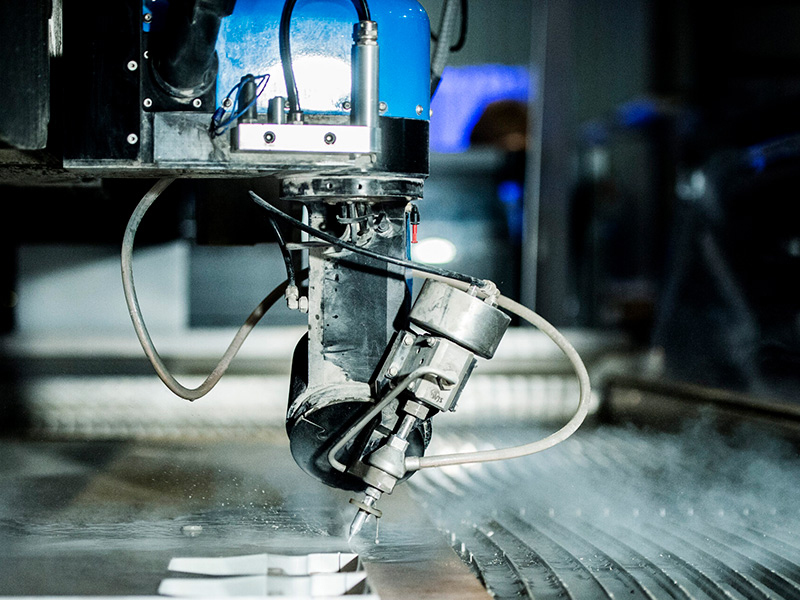

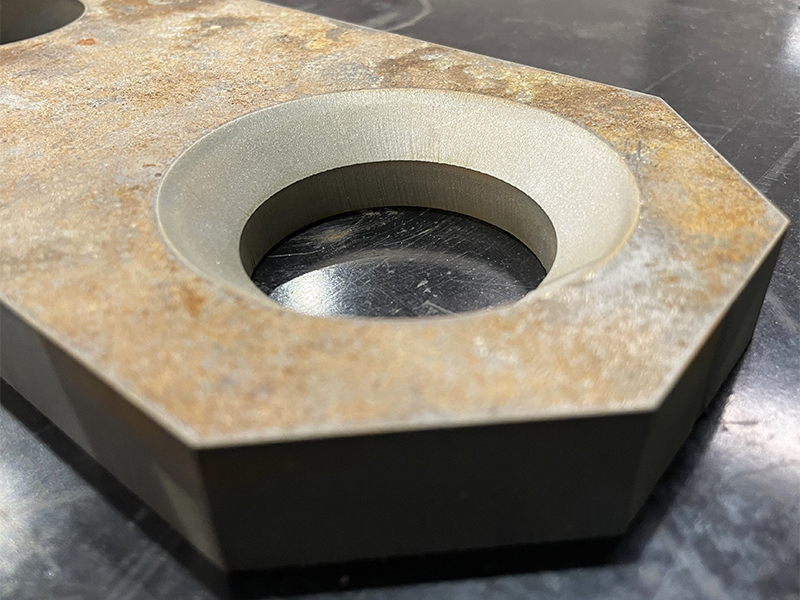

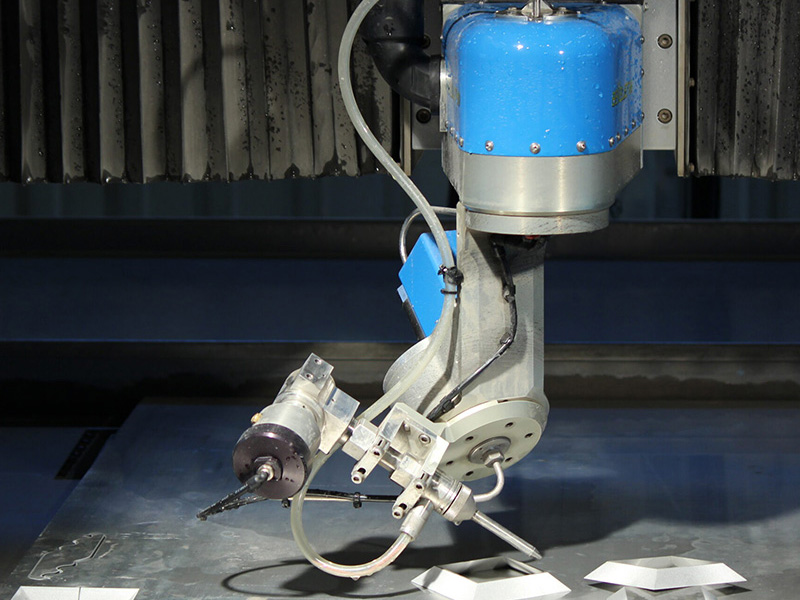

Offering unparalleled levels of efficiency, we here at Charles Day are extremely proud to introduce our latest machine investment: the Waterjet Sweden BevelJet 60. Regarded as one of the most advanced pieces of machinery available in the metal profiling industry, this innovative piece of technology is the newest addition to our suite of state-of-the-art profiling machines. Enhancing the capabilities of our already exceptional waterjet cutting services, the Waterjet Sweden BevelJet 60 allows for advanced waterjet bevel cutting – the latest addition to our long line of professional services.

Key Benefits of the Waterjet Sweden BevelJet 60

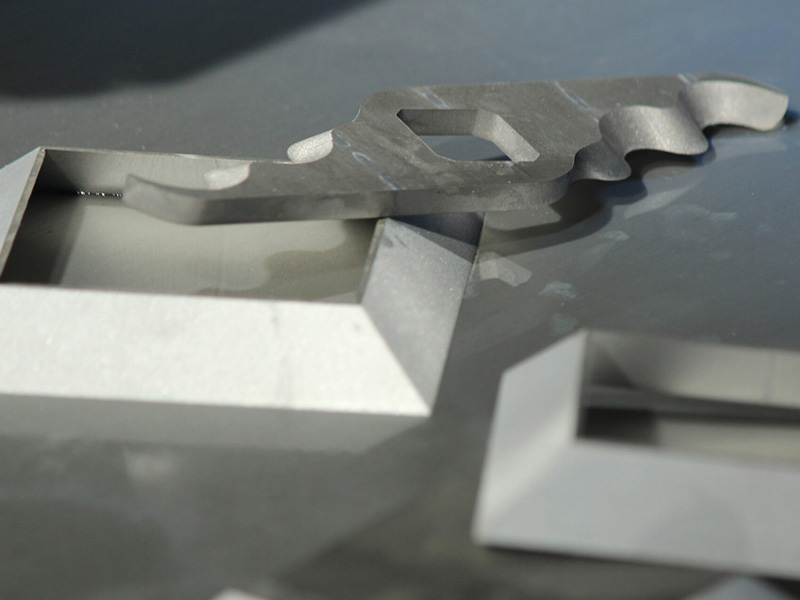

- Beveljet 60 head allows for 3D parts to be processed up to 60°

- 125hp pump allows for 6200 bar cutting

- Dual heads (3D and 2D) allows for simultaneous cutting of up to 6200 bars of pressure through each head

- Reduced production times

- Adjustable pressure for rapid cutting speed

- Cutting bed measuring 4m x 8.5m

Waterjet Cutting Service

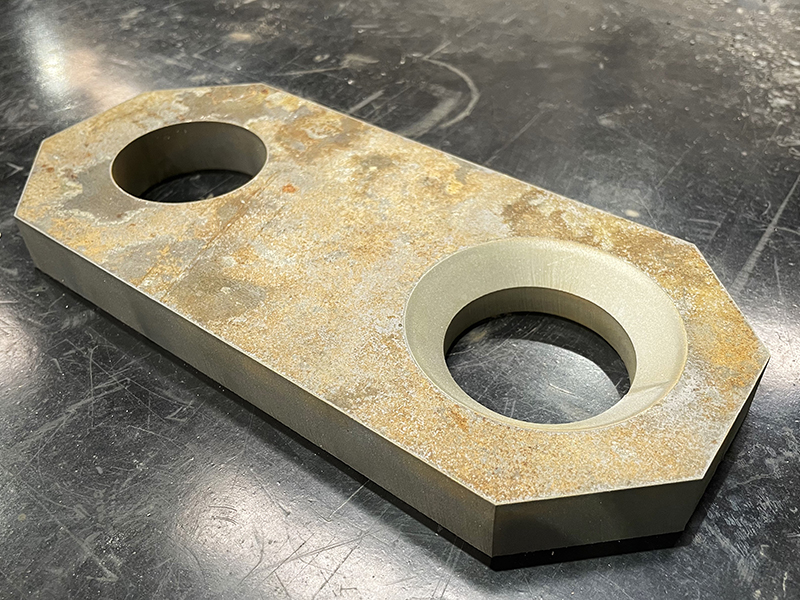

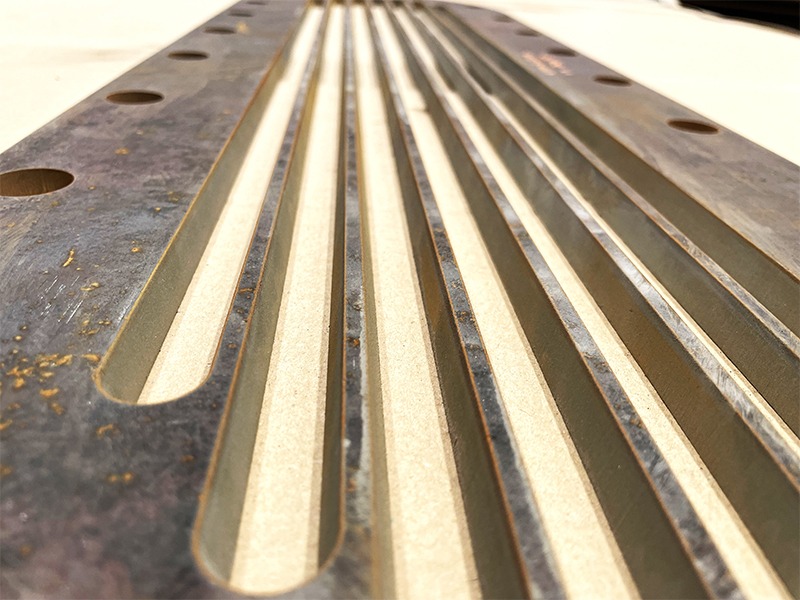

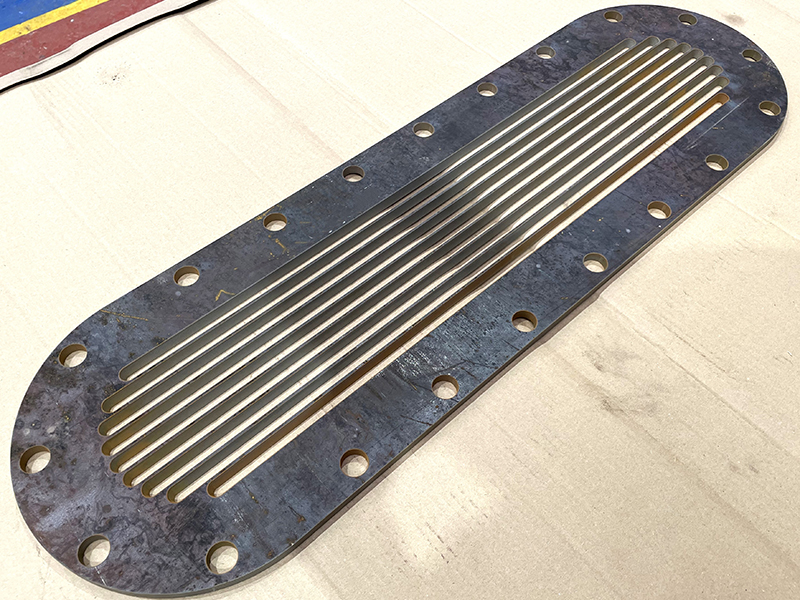

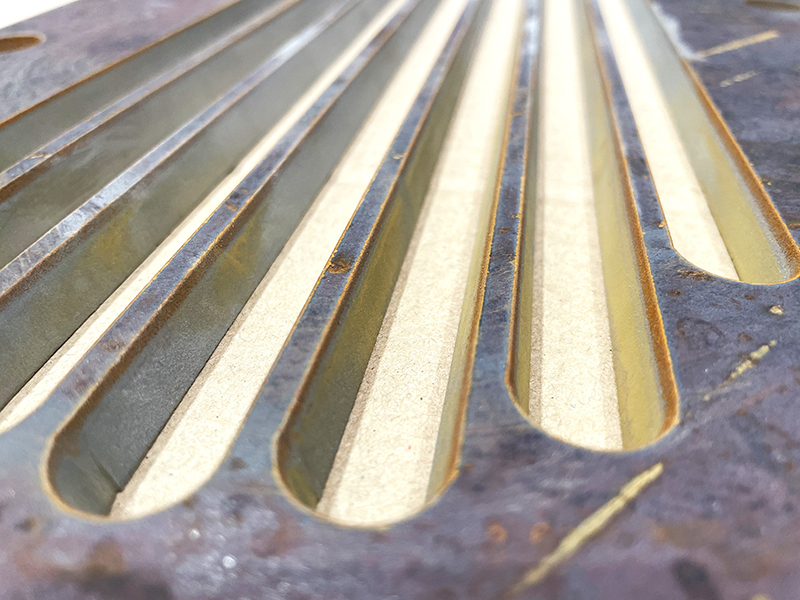

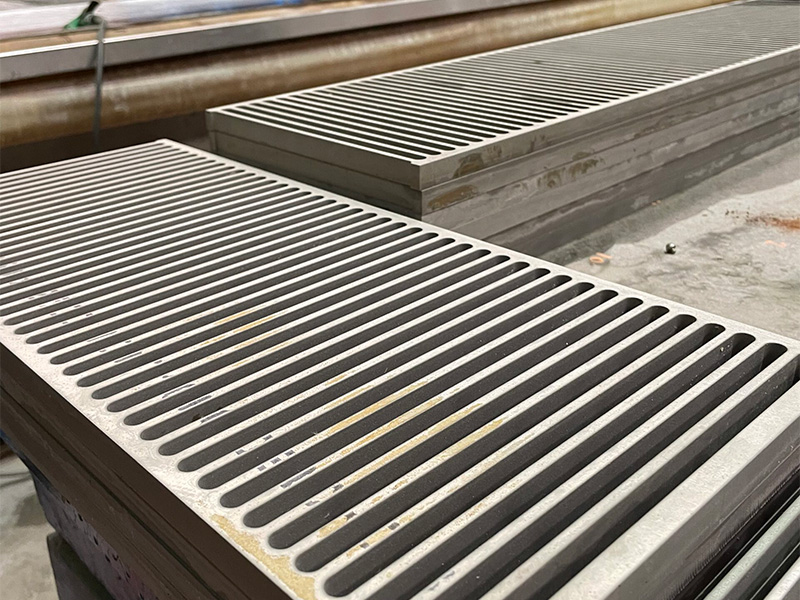

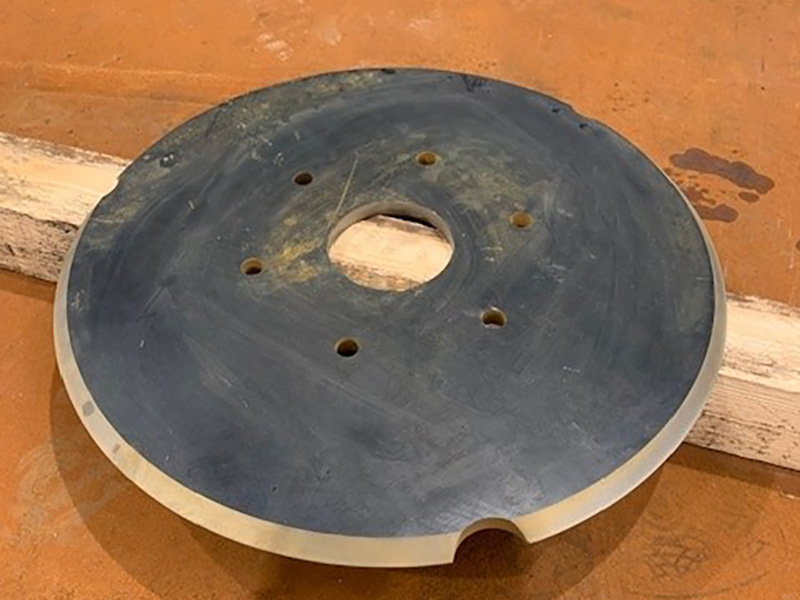

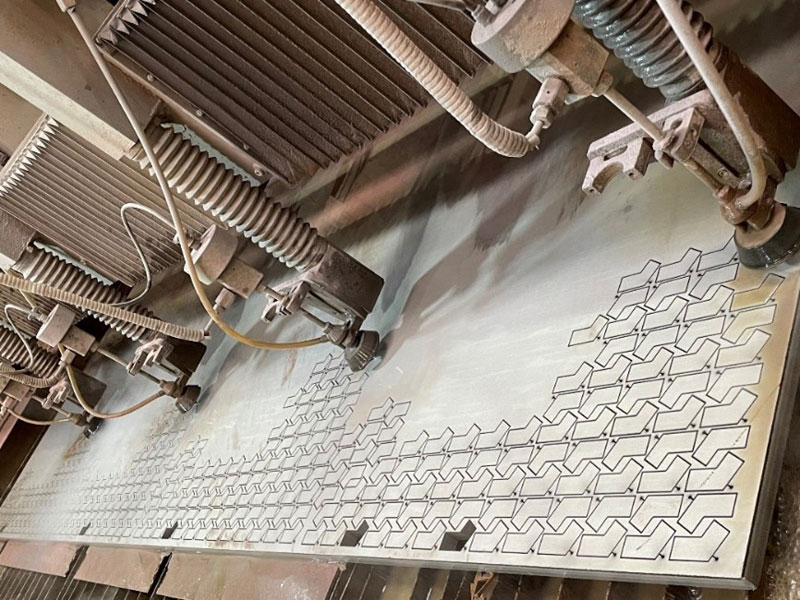

Waterjet cutting service for a wide range of materials measuring up to 9m x 4m using three of the UK’s largest cutting beds. These powerful multiheaded waterjet machines are accurate to +/-0.25mm. A highly versatile cutting technology, waterjet is able to cut through almost any material and produce highly complex profiles.

The ability to create precise cuts without causing substrate heat damage, known as heat affected zone or HAZ, is particularly useful for specialist applications such as nuclear and aerospace. Manufacturers working to meet stringent material specifications can rely on a cold cutting process like waterjet as the ideal solution to avoid material damage and deformation.

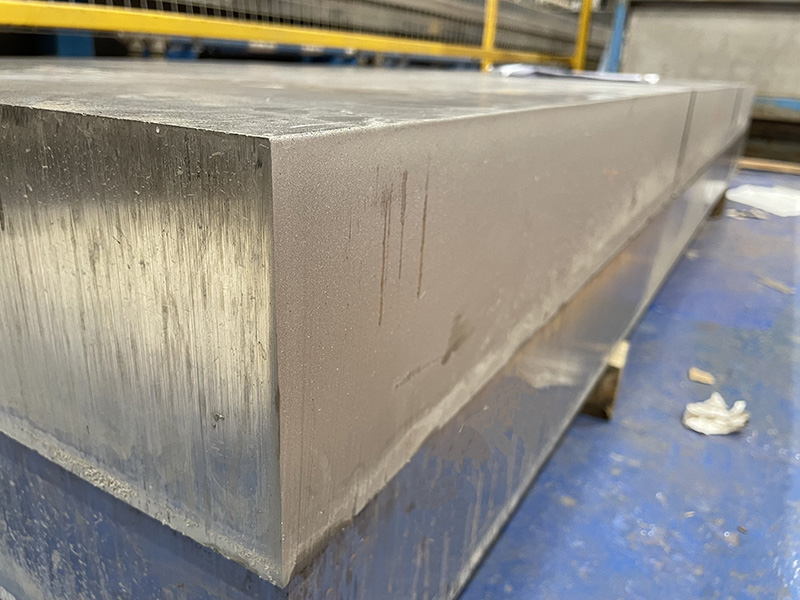

Waterjet cutting is suitable for a wide range of materials measuring up to 9 metres x 4 metres:

- Mild & Carbon Steels

- Aluminium & Alloys

- Stainless Steels

- Brass & Bronze

- Copper

- Carbon Fibre

- Plastics & Acrylic

- Glass

- Marble and Granite

Fast and Accurate Cutting

Charles Day Steels operate a 24-hour waterjet cutting service. Using a suite of three high-pressure multiheaded machines provides an unrivalled service capable of cutting highly complex profiles, fast. Continuous investment in water pump power and large cutting beds puts Charles Day at the forefront of outsourced waterjet cutting.

Established in 1977, waterjet operatives bring expertise to every job, delivering fast turnaround times without compromising of edge quality. Charles Day Steels draw on all relevant technologies to provide customers with a no-hassle, reliable cutting service – including mild and stainless steels, aluminum, marble, plastics, and more.

We can provide as much or as little of a one-stop-shop as our customers need. From sourcing material and passing on the benefits of our aggregated buying prices to fully optimised nesting via our in-group Smart Design Production service, we help customers achieve more with less.

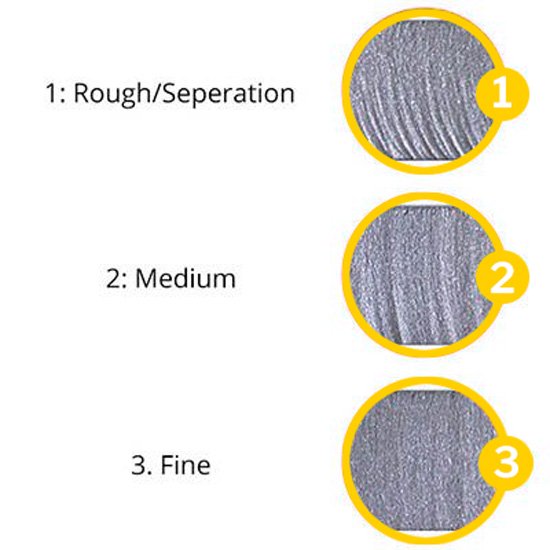

Edge Quality Scale

Waterjet is a highly accurate cutting process, capable of producing complex cuts in almost any material, hard or soft. Using a range of flow speeds, waterjet delivers differing grades of quality. Where edge quality is not critical, the fastest waterjet speed produces a rough edge. Faster throughput delivers the lowest price to manufacturers outsourcing cutting requirements.

The slowest flow speed produces the finest edge quality with a cut width of 1mm. Reduced throughput means achieving fine edge quality results in a higher cutting cost. The median point is a balance of medium flow speed to produce medium edge quality.

Abrasive waterjet cutting is primarily used for the hardest materials and allows Charles Day Steels to cut almost any material. Garnet, an abrasive agent, is added to the waterjet stream to boost cutting speeds for the hardest materials. Differing grades of abrasive, from course to fine, provide additional control to optimise both throughput and edge quality.

Unrivalled Cutting Capability

Waterjet is one of the most versatile cutting technologies. Able to achieve a top surface profiling tolerance of +-0.25mm and edge squareness of 1° draft angle through the material. Charles Days Steels provide both abrasive and pure waterjet cutting of almost any material.

Largescale Cutting

9m x 4m bed size

Highly Accurate

Tolerance of +-0.25mm

Fast Turnaround

Powerful, multiheaded cutting

FAQs

What is Waterjet Cutting?

Waterjet cutting is a precision cutting technique that uses a high-pressure stream of water, often mixed with an abrasive substance, to cut a wide variety of materials. This method is renowned for its accuracy, versatility, and clean cuts.

What Are the Key Benefits of the Waterjet Sweden BevelJet 60?

The BevelJet 60 features a dual head system (3D and 2D) for simultaneous cutting at pressures up to 6200 bars. Its 125hp pump and adjustable pressure ensure rapid cutting speeds. The large cutting bed (4m x 8.5m) accommodates large-scale projects, significantly reducing production times.

How Does the Waterjet Sweden BevelJet 60 Enhance Waterjet Cutting Precision?

With the Waterjet Sweden BevelJet 60, we can achieve a top surface profiling tolerance of ±0.25mm and edge squareness of 1° draft angle, ensuring highly accurate and precise cuts for complex profiles.

What Materials Can Be Cut with Waterjet Cutting?

Our waterjet cutting service at Charles Day Steels can handle a diverse range of materials, including metals like mild and carbon steel, aluminium, glass, marble, and more. The versatility of waterjet cutting makes it suitable for numerous industries.

How Thick Can Materials Be for Waterjet Cutting?

The waterjet cutting process is capable of cutting through materials of various thicknesses, typically up to several inches thick, depending on the material type and the specifics of the cutting machine.

What Are the Advantages of Waterjet Cutting Compared to Laser Cutting?

Waterjet cutting does not generate heat, making it ideal for materials that are sensitive to high temperatures. It also allows for cutting thicker materials and can handle some materials that laser cutting cannot, such as certain composites and metals.

How Precise is Waterjet Cutting?

Our waterjet cutting services offer high precision; accurate to +/-0.25mm. This level of accuracy makes it suitable for intricate designs and precise cutting requirements.

How Can I Get a Quote for Waterjet Cutting Services?

You can request a quote for our waterjet cutting services by contacting us directly with your project details, including material type, thickness, and design specifications. Get in touch with Charles Day Steels today and our team will provide a detailed and competitive quote.