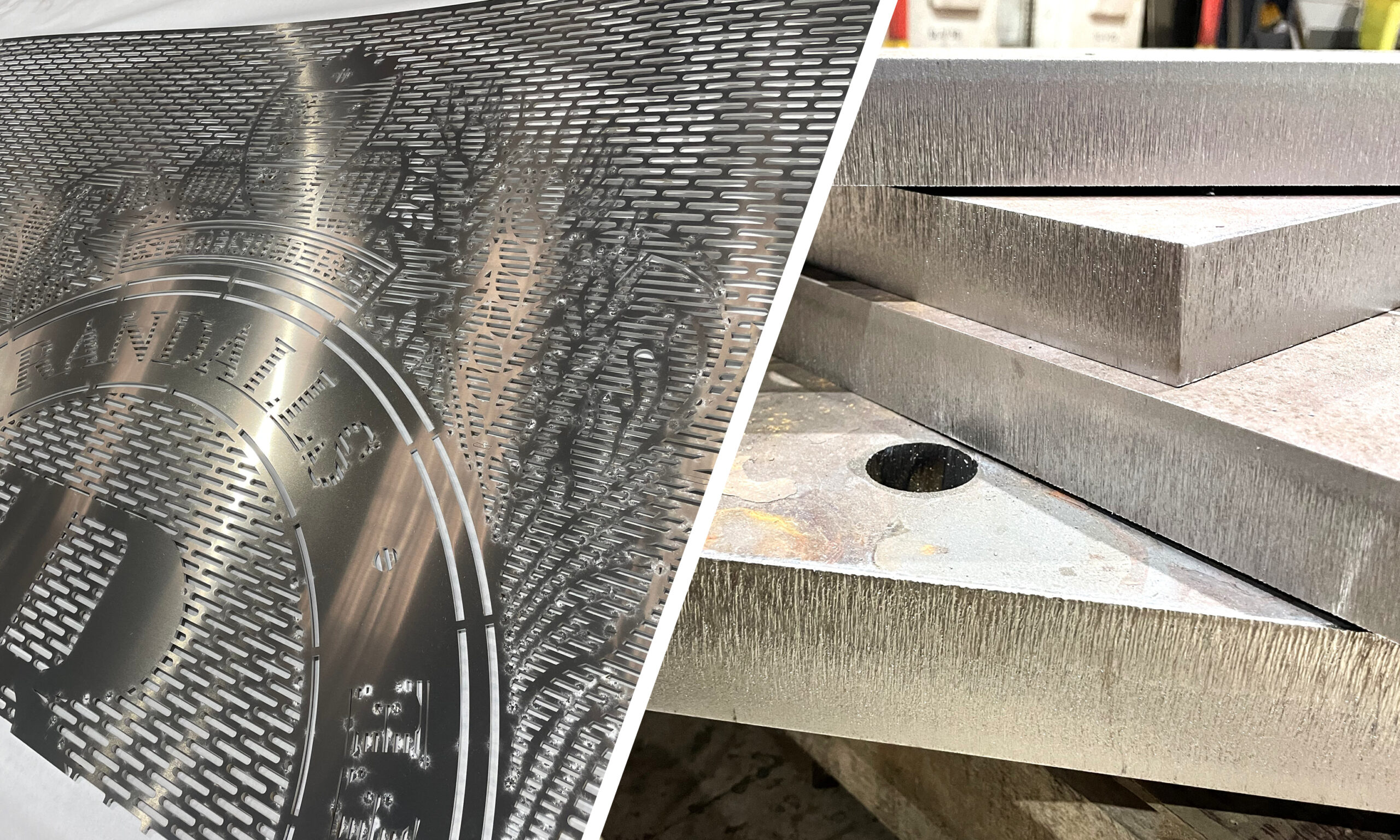

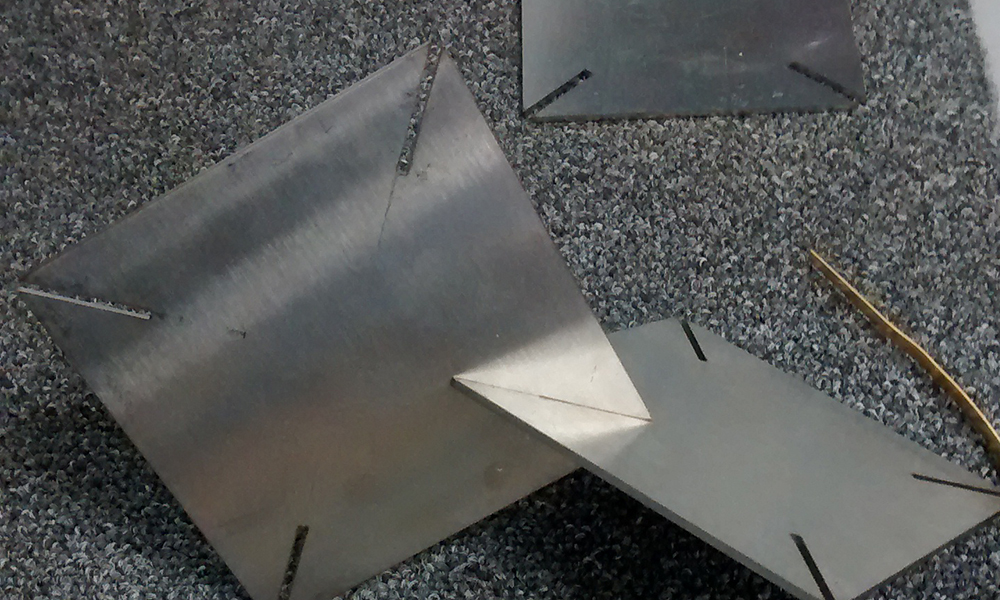

Stainless Steel Cutting Services: Precision Profiling and Fast Turnaround

One of the most popular and versatile metals on the market, stainless steel’s corrosion resistance and high-quality finishes make it widely used within numerous industries throughout the world. We possess extensive experience in cutting stainless steel sheets for a range of clients in the medical, design, architecture and male grooming sectors.

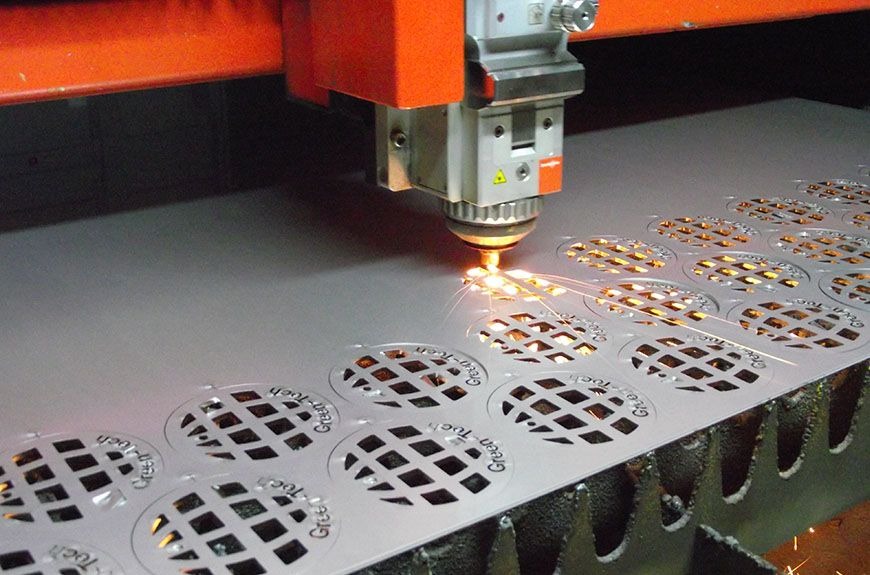

Our suite of powerful CNC laser cutting machines operates around the clock, capable of profiling a wide range of stainless steel grades and alloys with thicknesses of up to 50 mm. We maintain a diverse inventory of stainless steel grades and thicknesses in stock, and if unavailable, we can readily source them for you.

We keep a wide range of stainless steel grades and thicknesses in stock, however, If we don’t have a material in stock, we can usually source it within 24 hours. We can also cut your free-issue material, and test certificates can be supplied when requested.

We offer services to cut your free-issue material, and we supply test certificates upon request. Our 6 flatbed laser cutting machines and automation systems enable us to work seamlessly and ensure prompt delivery from drawing to delivery.

Why Choose Charles Day Steels for Stainless Steel Cutting?

As one of the UK’s leading metal profiling companies, our commitment to providing and improving upon our comprehensive stainless steel cutting facilities underscores our ethos of continuous self-reinvestment; always going above and beyond to provide our customers with the efficient, reliable and professional service they deserve. This commitment is exemplified by our dedication to quality assurance, diverse cutting and profiling portfolio, 24-hour production, range of metals in various sizes and thicknesses and competitive pricing.

With over four decades of experience and expertise in producing laser cut stainless steel solutions, we here at Charles Day Steels are proud to be your metal profiling partner.

THE ALL-IN-ONE

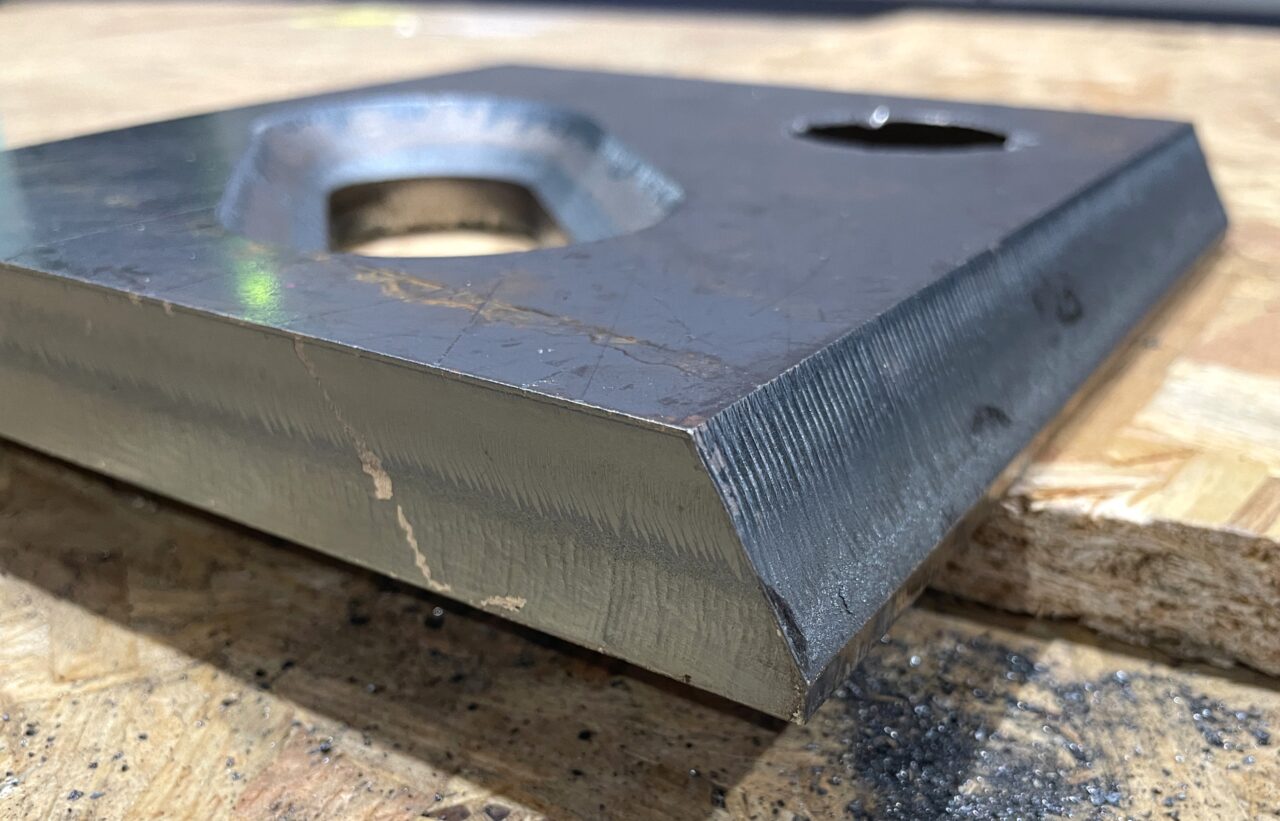

Boost Efficiency with Laser Bevel Cutting!

Save time and reduce costs with our advanced 50-degree Laser Bevel Cutting. Get fabrication-ready parts with built-in weld preps, eliminating manual grinding and speeding up assembly. Stronger joints, faster turnaround, lower costs.

Benefits of Laser Cut Stainless Steel by Charles Day Steels

Laser cutting mild steel offers a range of benefits and is recognised for its cost-effectiveness, high precision, and versatility, making it a preferred material for various industries. From structural fabrication and machinery and equipment to agricultural equipment and storage tanks and containers, mild steel offers unrivalled reliability and durability. Some of the key advantages of laser cut mild steel include:

Precision

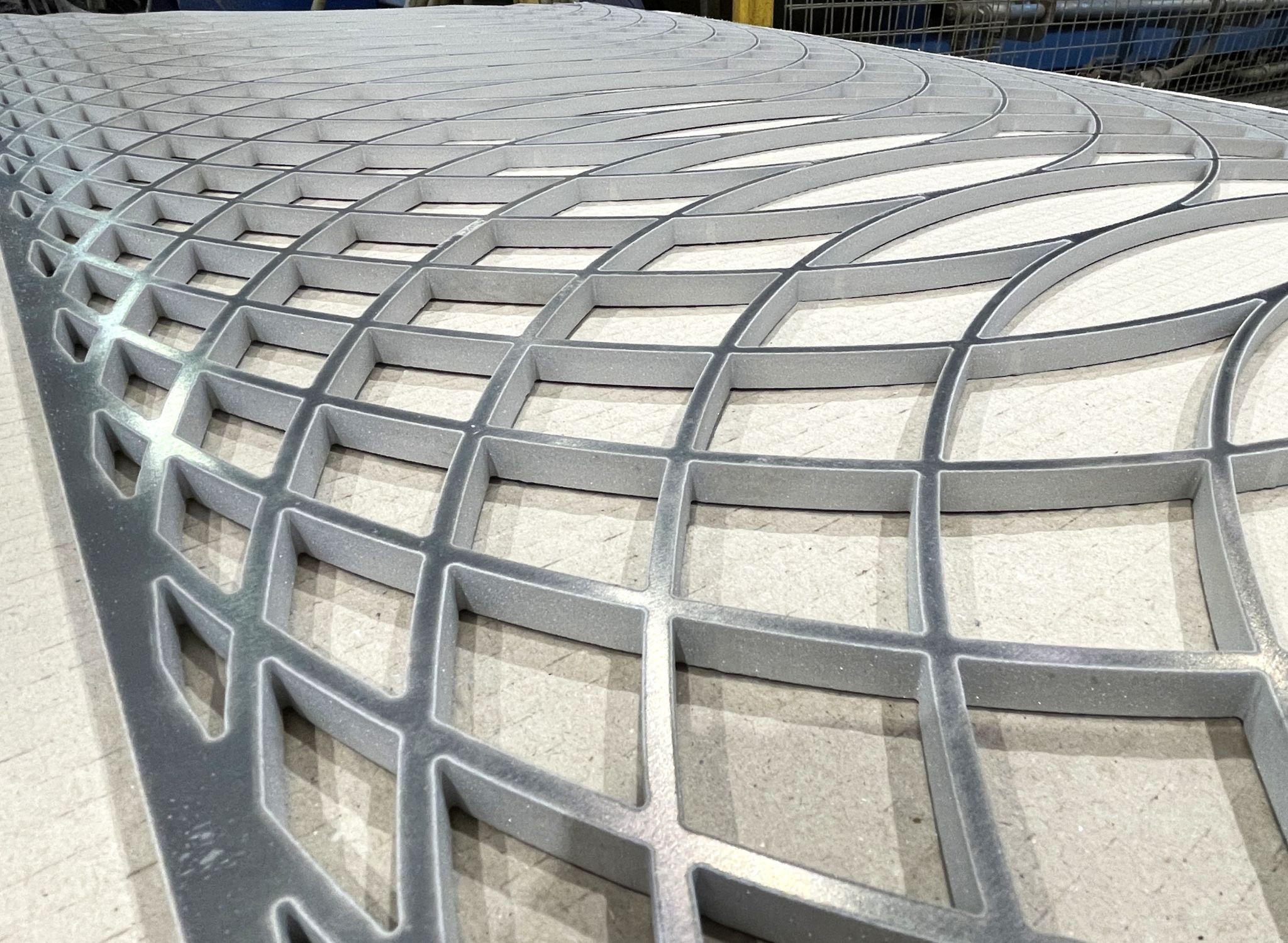

Mild steel can be cut with high precision and accuracy, allowing for intricate and complex designs to be cut with minimal error.

Versatility

Mild steel is highly versatile and can be easily fabricated into different shapes and sizes, making it suitable for various applications, and providing flexibility in design and construction.

Non-contact Cutting

Laser cutting is a non-contact process, which means there is no direct mechanical force applied to the material. This reduces the risk of material distortion or damage.

Minimal Material Waste

Laser cutting minimises material waste due to its precision cutting capabilities. This helps optimise material usage and reduce costs associated with material scrap.

Clean Cuts

Laser cutting produces clean, smooth edges without the need for secondary finishing processes, reducing the need for additional machining or deburring. This helps save time and labour costs.

Affordability

Mild steel is relatively inexpensive compared to other metals, making it a cost-effective choice for many applications; making it accessible for a wide range of projects and industries.

Typical Stainless Steel Cutting Applications:

Due to its versatility, stainless steel can be used for a huge range of applications, some of which include:

Domestic (cutlery, sinks, razor and knife blades)

Architectural/Civil Engineering (steel furniture, structural sections, decorative panels)

Oil, Gas and Petrochemical

Medical (surgical equipment, hospital equipment)

Hospitality (catering equipment, brewing, distilling)

Storage (water storage tanks, garage doors)

Sheet Metal Laser Cutting Thicknesses

With a plethora of in-house laser cutting capabilities, we can laser cut sheet metal in a variety of thicknesses depending on the material selected.

Laser Cut Thickness (mm)

Stainless Steel Cutting Capabilities

Maximum Cutting Size

6m x 2.5m (6000mm x 2500mm) – For larger sheet sizes we suggest plasma or waterjet cutting.

Maximum Material Thickness

50mm

Minimum Material Thickness

0.25mm

Complex Details

Our CNC driven laser cutting machines are able to process even the most complex and intricate designs.

Cutting Tolerances

View our laser cutting tolerances here.

Cutting Edge Quality

Laser cutting stainless steel provides a smooth finish quality, although this is sometimes degraded slightly on thicker sheets. As we shroud the laser in Nitrogen gases, it prevents oxidisation ensuring we achieve a clean, blemish-free cut, ready for welding without any extra machining.

Stainless Steel Cutting Grades

We’re able to laser cut stainless steel in all grades, some of the more common grades we get asked to cut include:

- SS304 / 1.4301 Austenitic

- SS304L / 1.4307 Austenitic

- SS316 / 1.4401 Austenitic

- SS316L / 1.4404 Austenitic

- 3CR12 / Nirosta 4003 / 1.4003 Ferritic

We also offer laser profiling of specialist stainless steels such as:

- 316Ti

- 321 / S32100

- SS316 / 1.4401 Austenitic

- 430 / 1.4016 Ferritic

- Duplex

- Super Duplex

- Zeron

- Shim Steel

We are laser cutting more and more nickel based, stainless steel alloys, also know as “exotic metals” including:

- Inconel Alloy 625

- Incoloy Alloy 800/800H

- Incoloy Alloy 825

- Hastelloy Steel

If the stainless steel grade you require is not in this list, we should still be able to source and cut it. Please contact us with your exact grade requirements.

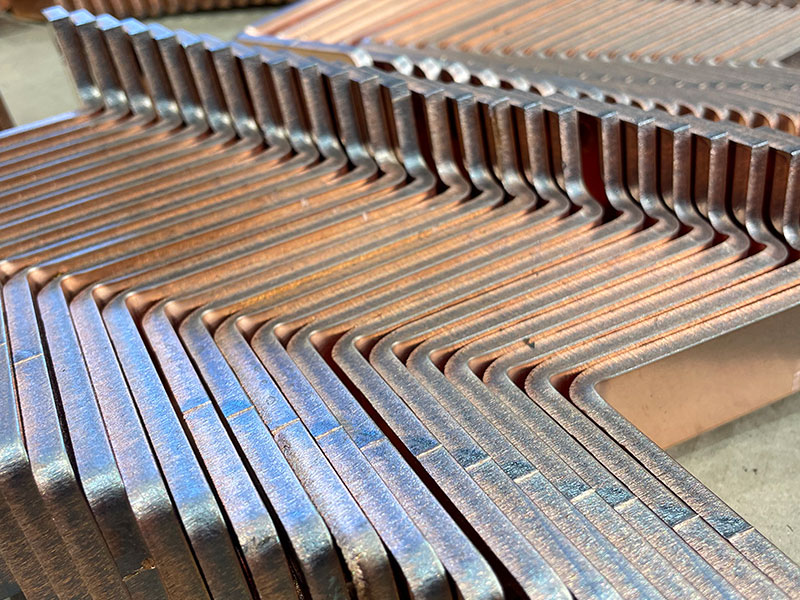

In-House Bending and Pressing

Charles Day Steels enhances our flatbed cutting solutions with comprehensive in-house metal bending and pressing services. Our facility supports swift project completion and continuous 24-hour production, streamlining your project’s assembly phase while ensuring top-tier quality.

Our capabilities extend to bending and pressing an extensive variety of materials, including mild steel, stainless steel, aluminium, copper, and others. For further details about our metal bending and pressing offerings, please reach out to our team.