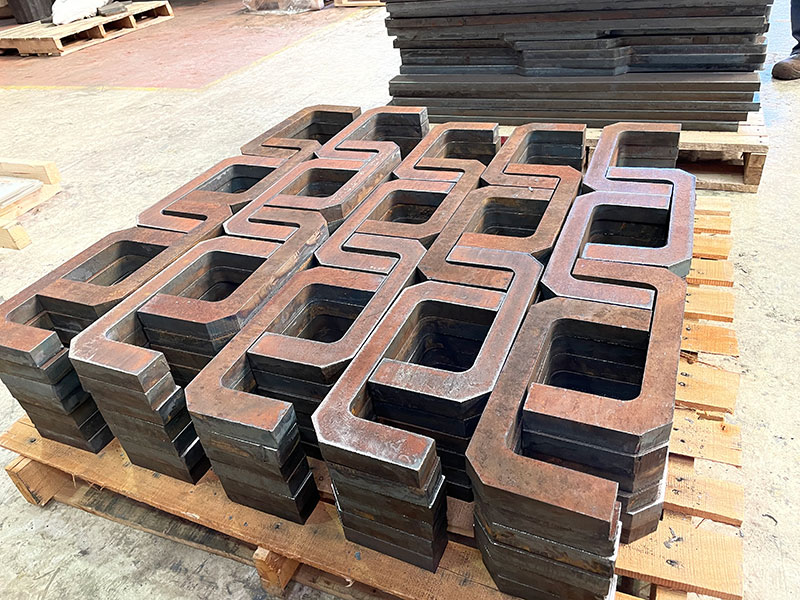

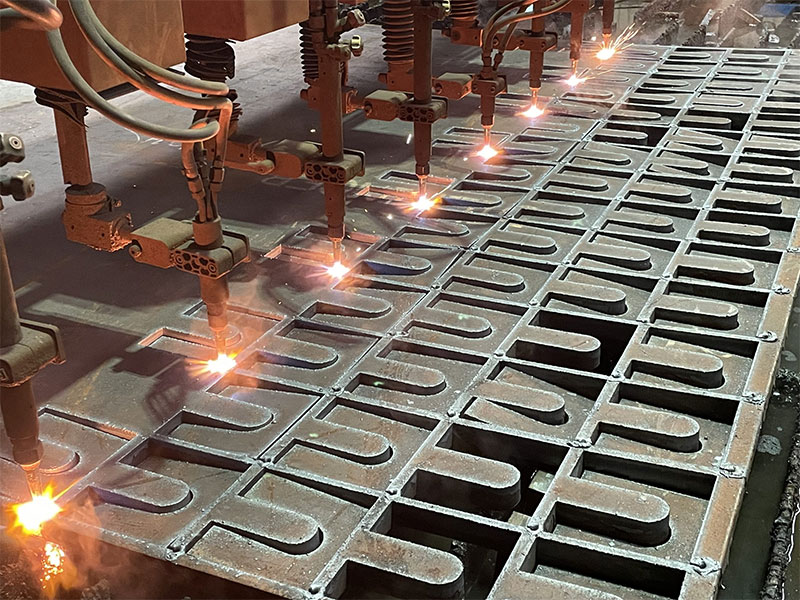

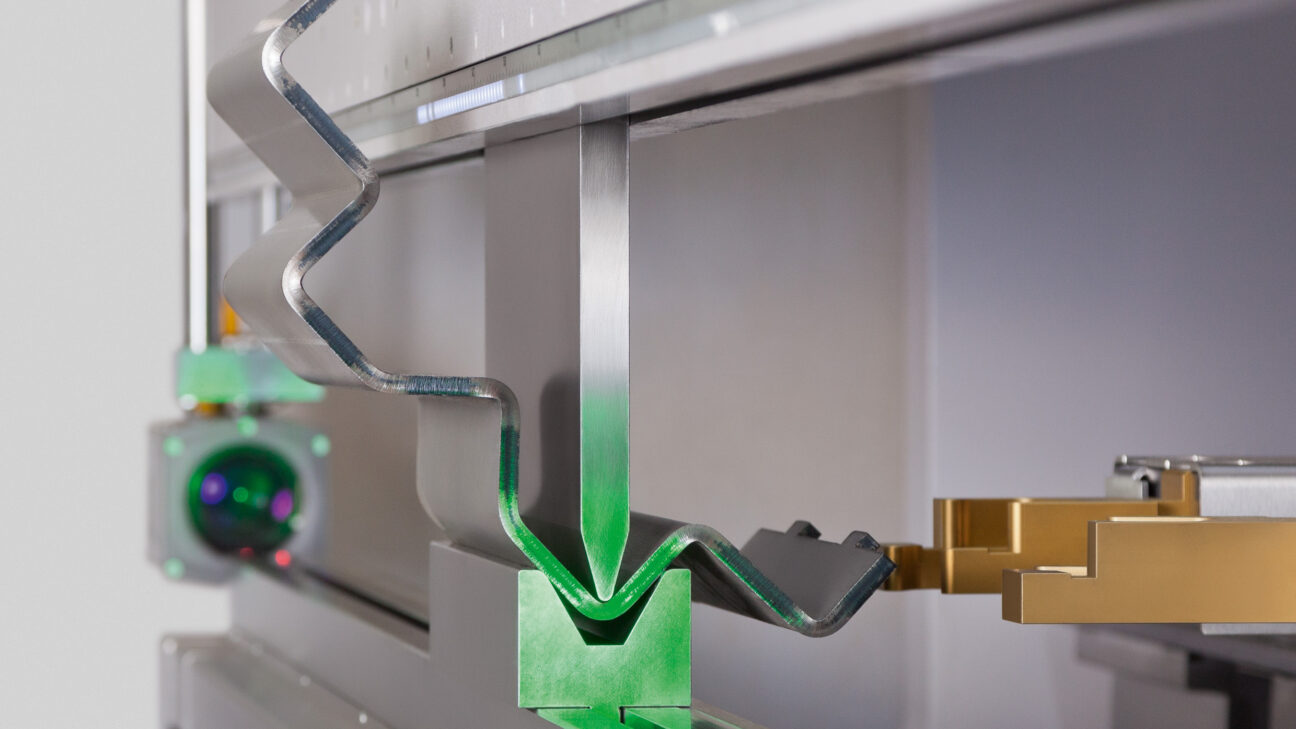

Flame cutting steel, otherwise known as oxy-acetylene cutting, is an efficient and cost-effective method of profiling steel.

At Charles Day Steels, we have over 45 years’ of experience as flame cut steel suppliers. Our accurate in-house programming ensures cost-effective processing and material is finished and treated to customer’s own individual specifications.

Flame Cutting Capabilities

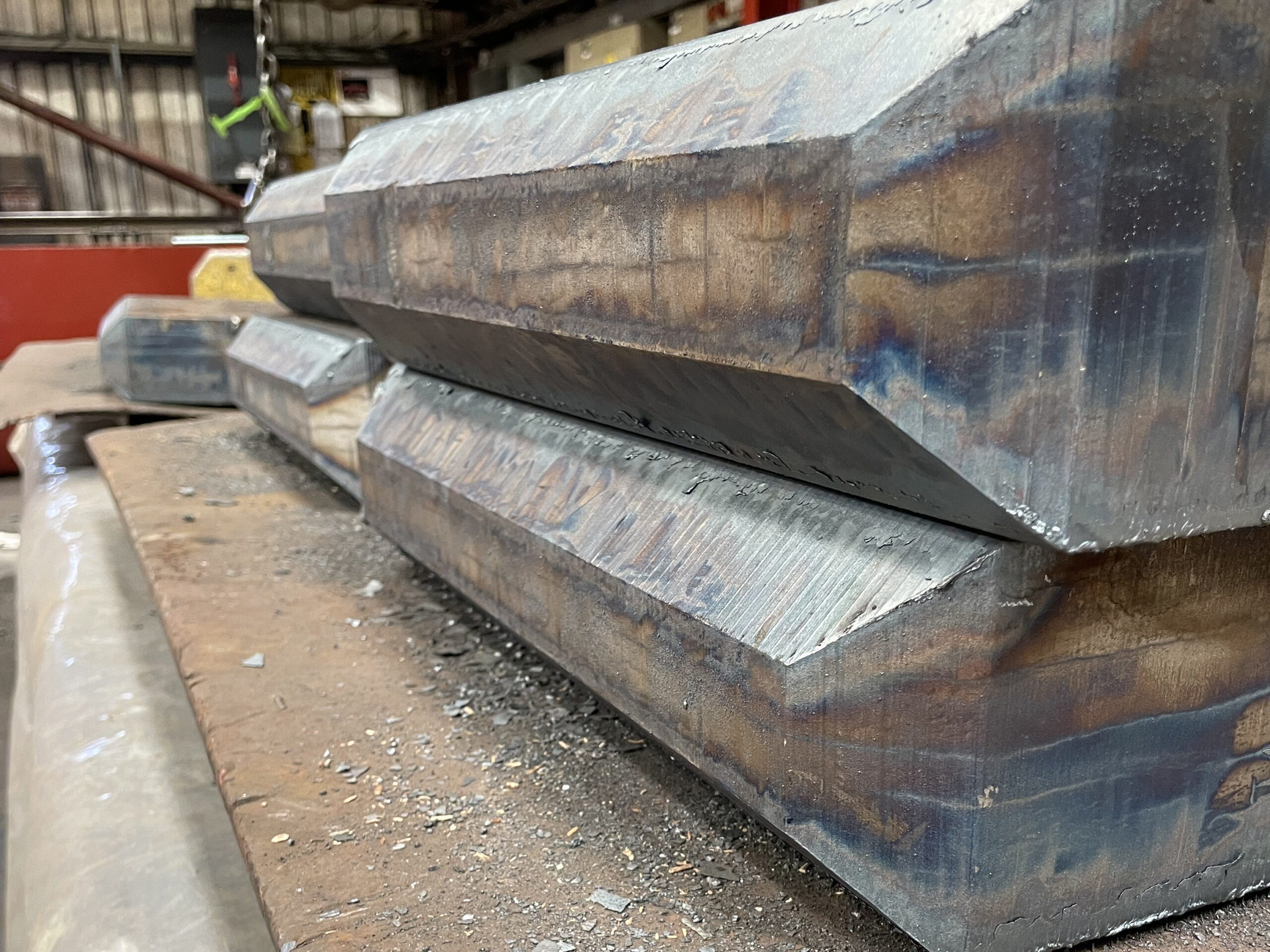

With multi-head cutting machines we can offer excellent cost savings on large production runs even on thick material such as mild steel up to 270mm thick. Our large cutting beds (42m x 5m), coupled with our multi-head flame profiling machines, make flame cutting the ideal choice for performing high production runs on short lead times at a low cost per part.