As a leading provider of profile cutting services, including laser, waterjet, flame, and more, we here at Charles Day Steels understand more than most that the marriage of technology and expertise has revolutionised the landscape of metal fabrication, enabling the delivery of high-quality, custom-cut parts with unparalleled precision and speed.

Established in 1976, we have continually pushed the boundaries of innovation, investing in the latest technologies to meet the evolving needs of our clients. One such technology that has played a pivotal role in our success is the use of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software.

What is CAD/CAM?

CAD/CAM refers to the use of computer technology to aid in the design and manufacturing of products. CAD/CAM software serves as the digital backbone of the precision profile cutting process, allowing for the seamless translation of design concepts into tangible, precisely cut components.

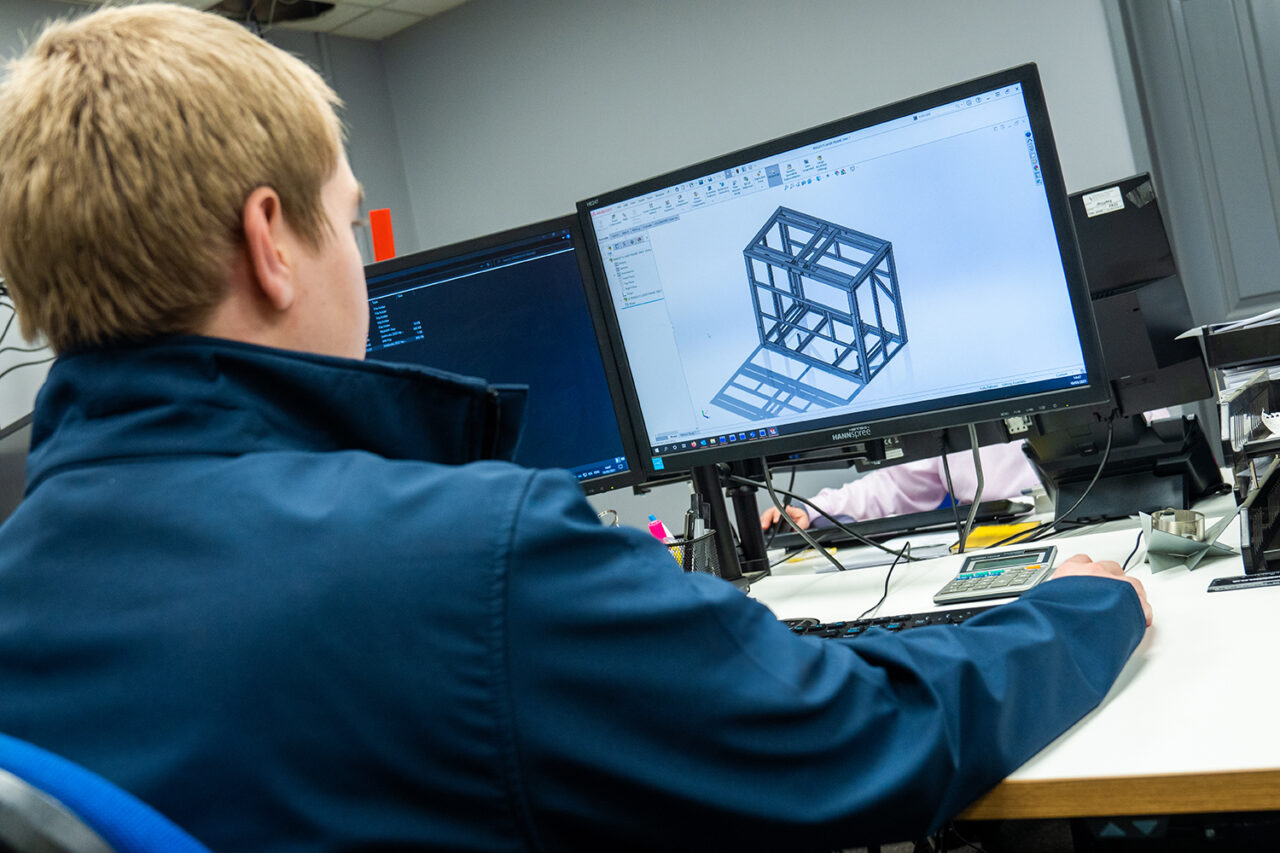

Computer Aided Design involves the creation, modification, and optimisation of a design using computer software. Engineers, architects, and designers use CAD software to create detailed 2D or 3D models of products, buildings, or parts. These models can be easily manipulated, refined, and analysed before the manufacturing process begins.

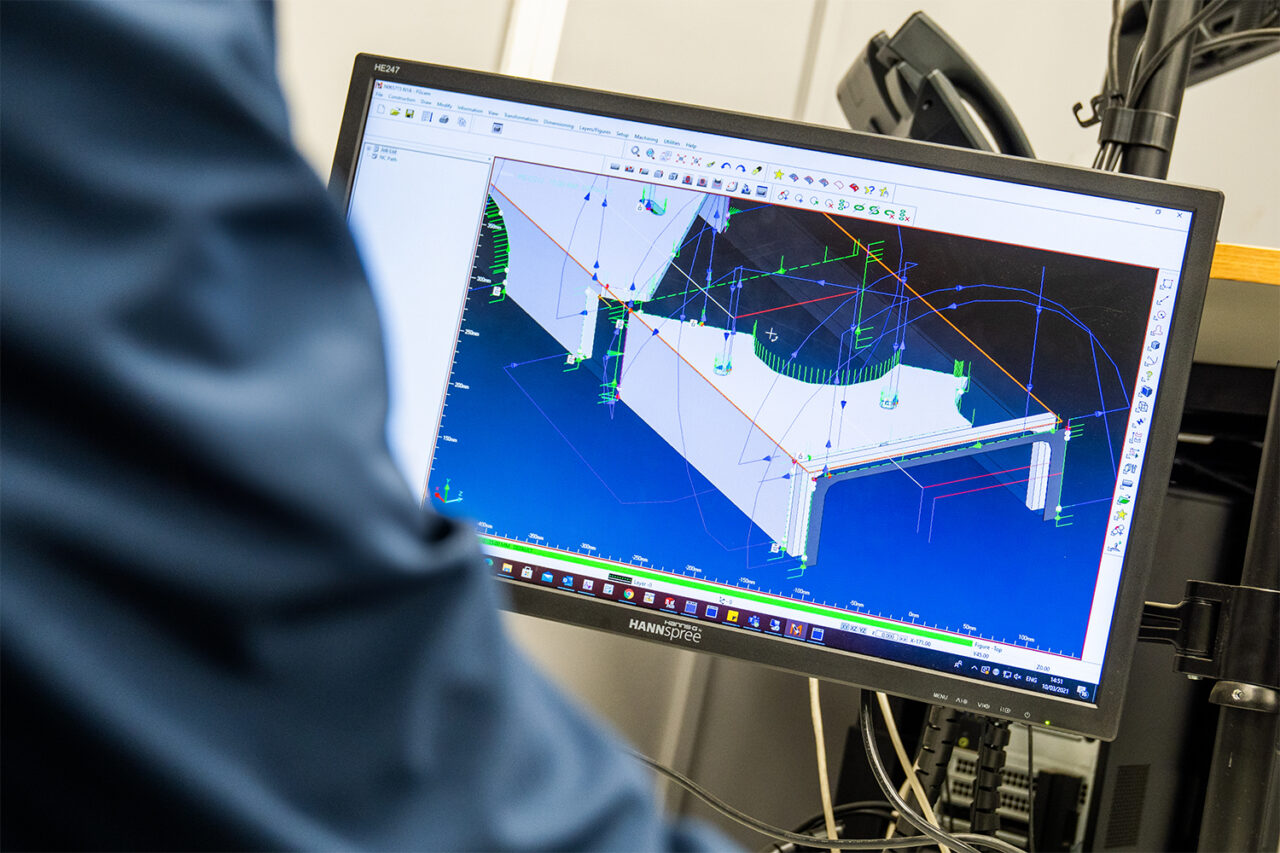

Computer Aided Manufacturing, on the other hand, involves using computer software and machinery to control and automate manufacturing processes. This includes activities such as machining, milling, turning, and other processes involved in turning raw materials into finished products. CAM software takes the design created in CAD and generates instructions for machines to follow, guiding them through the manufacturing process with precision and efficiency.

How Does CAD/CAM Improve Precision Profile Cutting?

From intricate geometries to complex contours, CAD/CAM software empowers engineers and fabricators to visualise, simulate, and optimise every aspect of the cutting process before a single piece of metal is touched, and significantly improves precision profile cutting in several ways:

Accurate Design Representation

CAD software allows engineers and designers to create precise digital models of the desired parts or components. These models can be created with exact dimensions, tolerances, and geometric features, ensuring that the final product matches the intended design.

Simulation and Visualisation

CAD software often includes simulation capabilities that allow users to visualise the cutting process before it occurs. This helps in identifying potential issues or errors in the design that could affect the precision of the cutting process.

Optimised Toolpath Generation

CAM software takes the digital design created in CAD and generates toolpaths for the cutting machine to follow. CAM algorithms optimise these toolpaths to minimise material waste, reduce machining time, and ensure precise cutting of the desired profiles.

Automatic Error Correction

CAD/CAM can automatically detect and correct errors in the design or toolpath generation process. This helps in maintaining precision throughout the cutting process and reduces the need for manual intervention.

Integration with CNC Machines

Many CAD/CAM software packages are designed to seamlessly integrate with CNC (Computer Numerical Control) machines. This integration allows for direct communication between the software and the cutting machine, ensuring that the programmed toolpaths are executed accurately.

Complex Geometric Capabilities

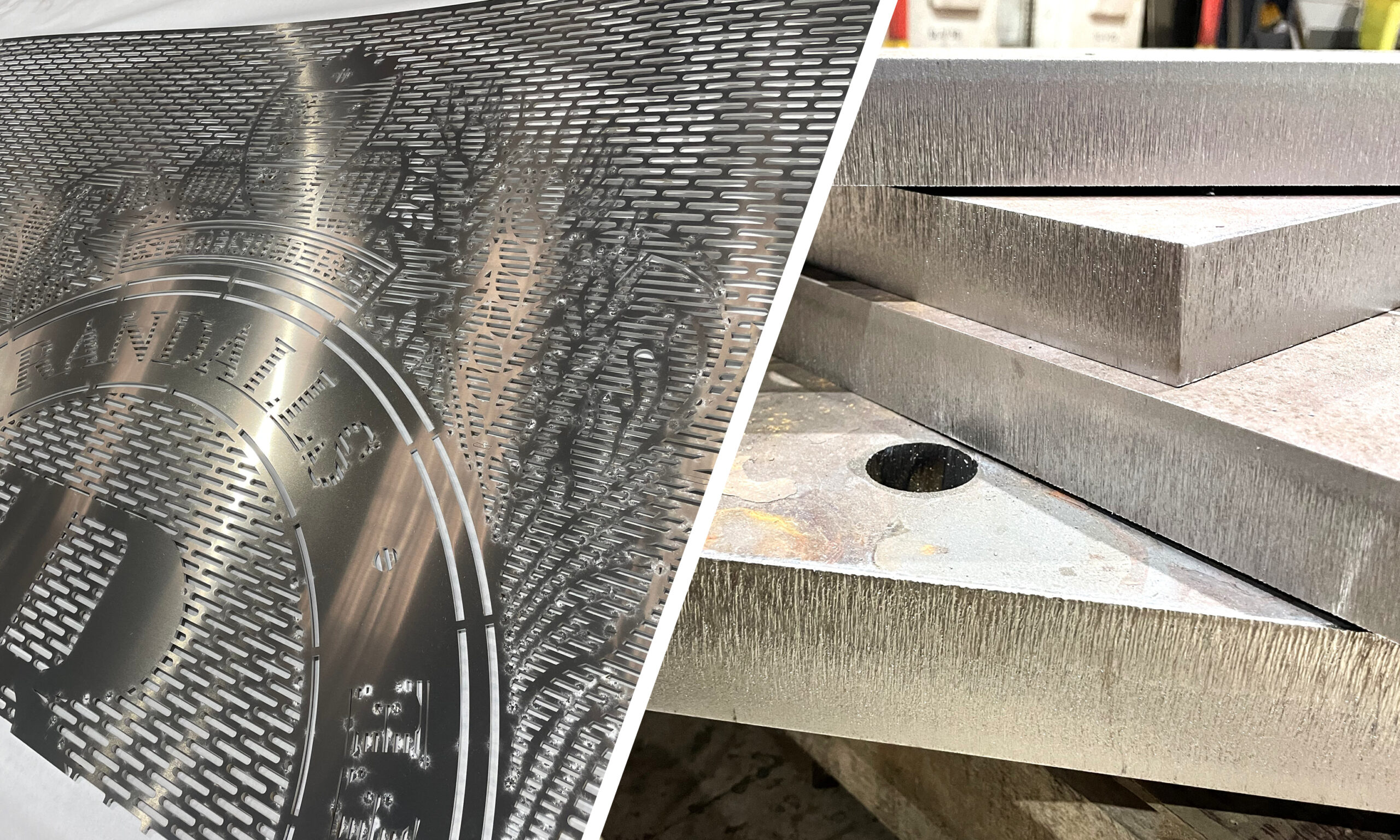

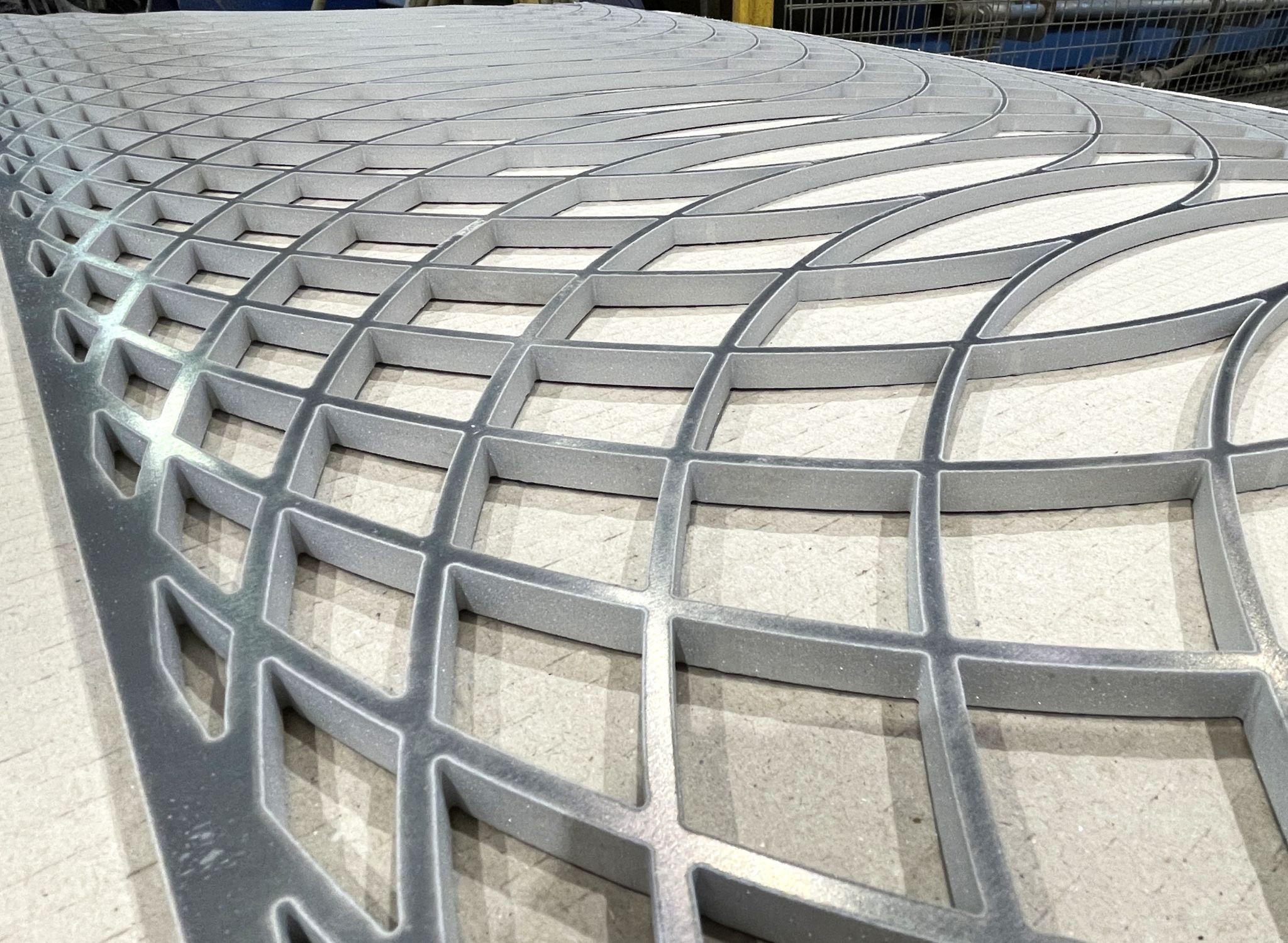

CAD/CAM software can handle complex geometric shapes and profiles with ease, allowing for the precise cutting of intricate designs that would be difficult or impossible to achieve manually.

Repeatable Accuracy

Once a cutting program is created using CAD/CAM, it can be saved and reused for future production runs. This ensures consistent, repeatable accuracy across multiple batches of parts or components.

How Charles Day Steels Uses CAD/CAM to Our Advantage

Our commitment to quality and expertise is reflected in our meticulous approach to utilising CAD/CAM. By leveraging industry-leading software platforms, our team of skilled engineers can accurately model and simulate the entire cutting process, identifying potential issues and optimising cutting parameters for maximum efficiency.

The power of CAD/CAM software lies not only in its ability to design and simulate, but also in its seamless integration with our fleet of cutting machines. Through advanced Computer Aided Manufacturing functionalities, such as toolpath optimisation and nesting algorithms, Charles Day Steels can maximise material utilisation, minimise waste, and reduce production times, ultimately delivering cost-effective solutions to our clients. This starts at point of enquiry, with CAD/CAM built into our quoting system customers receive quick responses with accurate prices.

Contact Charles Day Steels for CAD/CAM Precision Profile Cutting

CAD/CAM software serves as the backbone of Charles Day Steels’ diverse profile cutting services. Whether it’s cutting intricate patterns for components or fabricating large-scale structural sections for architectural projects, our state-of-the-art CAD/CAM capabilities ensure precision, accuracy, and consistency across every job.