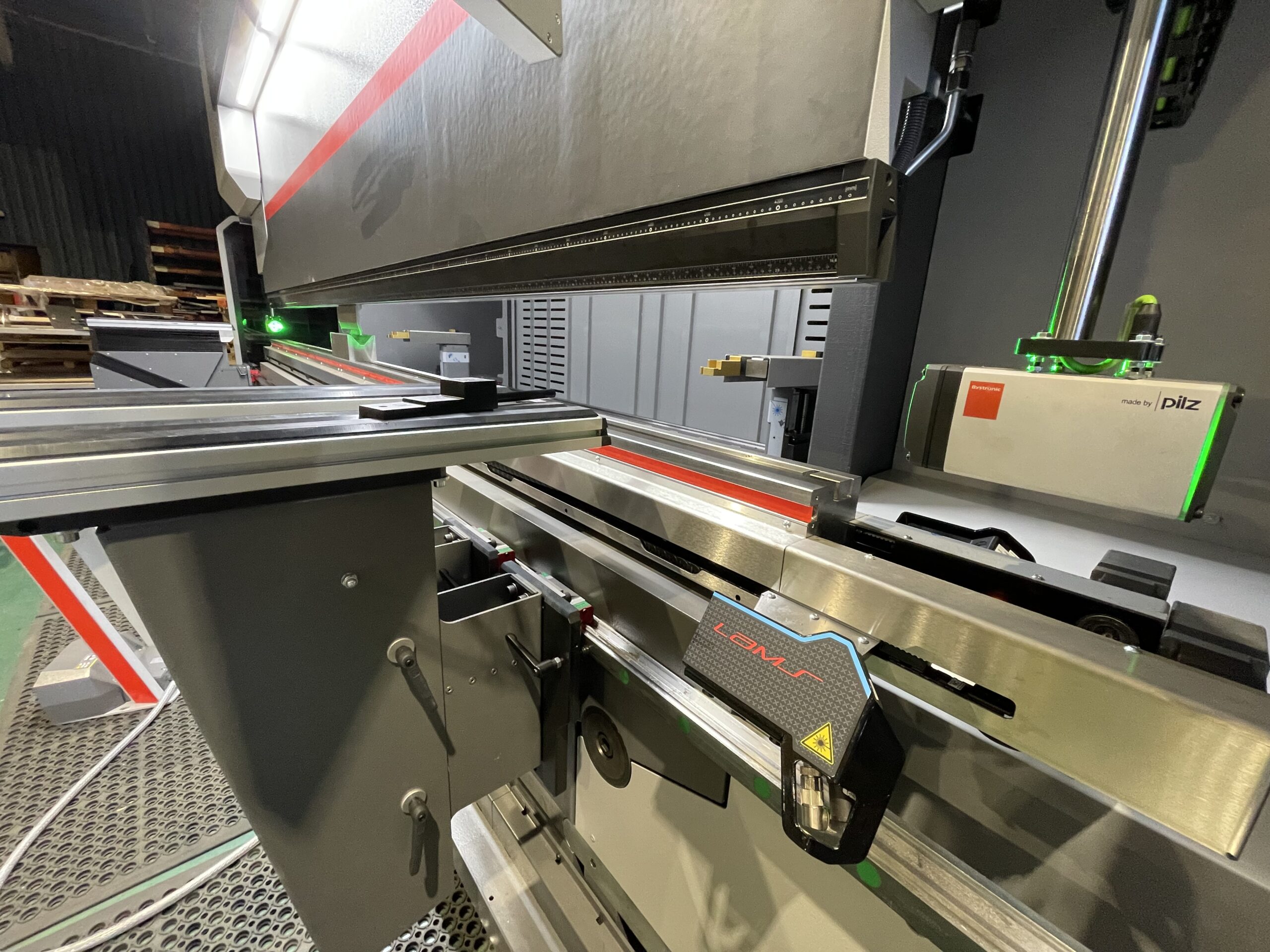

Boasting over four decades of experience and rooted in Sheffield’s rich steel heritage, Charles Day Steels is thrilled to introduce our latest cutting-edge machinery acquisition – a new Bystronic Xpert Pro 320/4100 Press Brake. This state-of-the-art machine is engineered to cater to a wide spectrum of bending requirements with unparalleled efficiency and quality; emphasising our ongoing investment strategy and commitment to advancing our bending and sheet metal pressing services.

Providing Cutting-Edge Solutions For 40+ Years

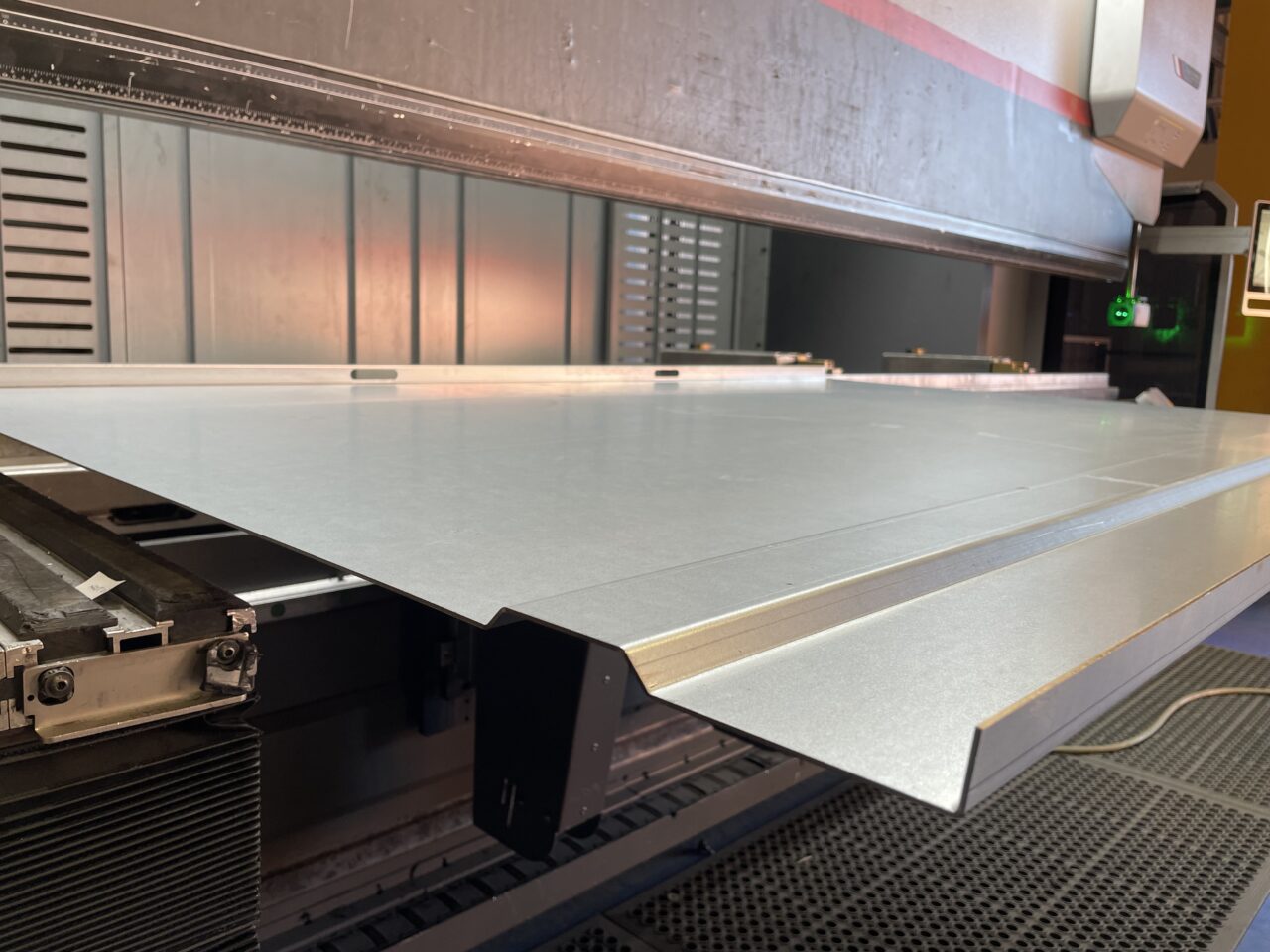

Building on a foundation of excellence and innovation, our latest in a long line of machine investments underscores our commitment to providing customers with cutting-edge solutions. This strategic move not only improves our in-house capabilities but also broadens the range of services available to our clientele. Boasting a tonnage of 320 tons and a bending length capacity of 4100 mm, this newest investment marks a significant upgrade over our previous capabilities; allowing us to accommodate larger and thicker materials, and expand our service offerings to include more complex and demanding projects. With this investment, Charles Day Steels reinforces our position as a leader in the metal processing industry, catering to a diverse range of client needs with precision and flexibility.

Renowned for its unparalleled precision and flexibility, this machine investment is a game-changer in the industry, equipped with dynamic crowning and Pressure-Reference technology to ensure the highest repetition accuracy and consistent quality across all projects. Its modular machine concept, coupled with a broad power spectrum, allows for the optimal configuration for specific sheet metal work, significantly enhancing production efficiency and flexibility.

Charlie Day, grandson of the founder and Sales and Business Development Director at Charles Days, had this to say about their latest investment:

“With our larger cutting beds and higher power lasers, the demand from customers for larger, thicker, and more complex parts is growing, so naturally we invest to satisfy that demand.”

Expanding On Excellence

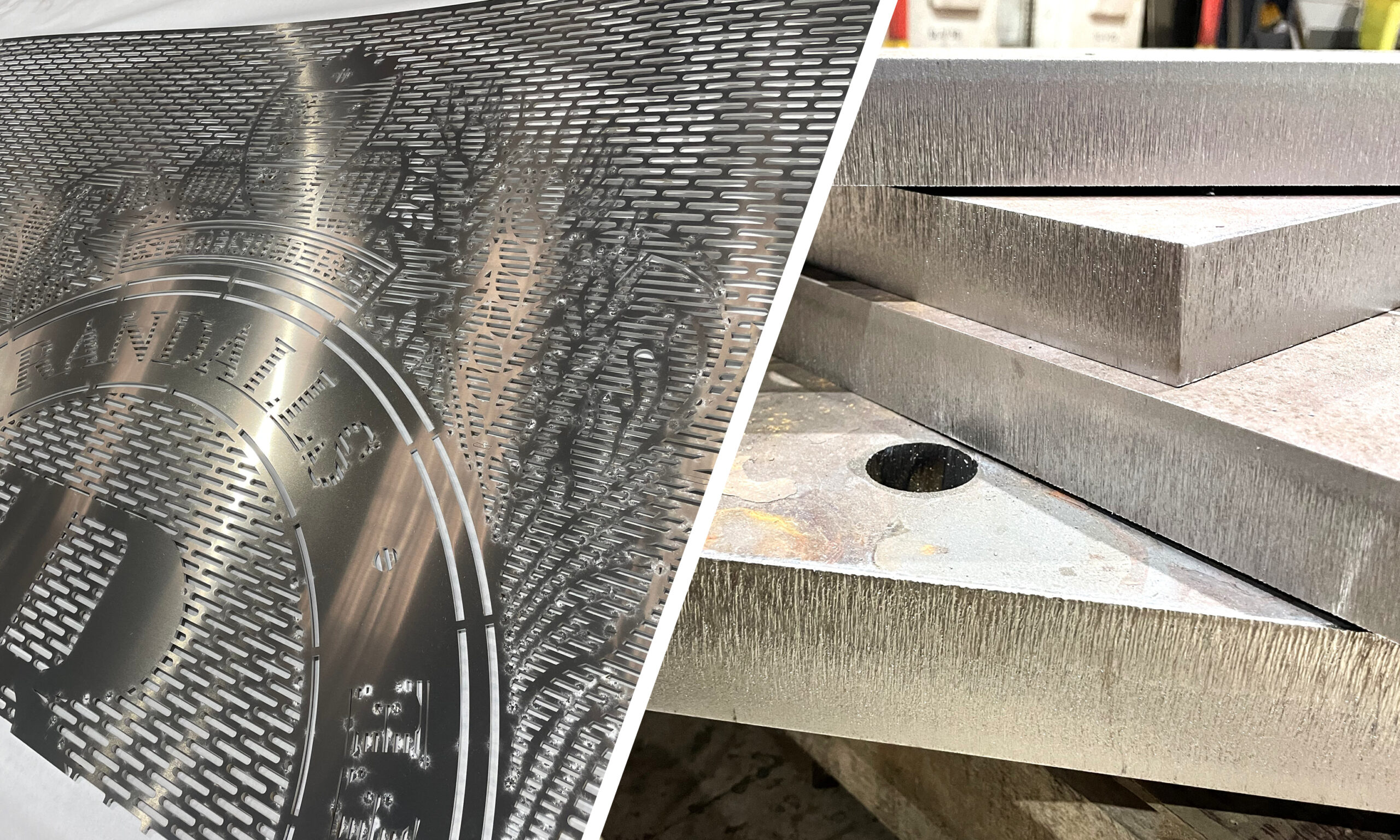

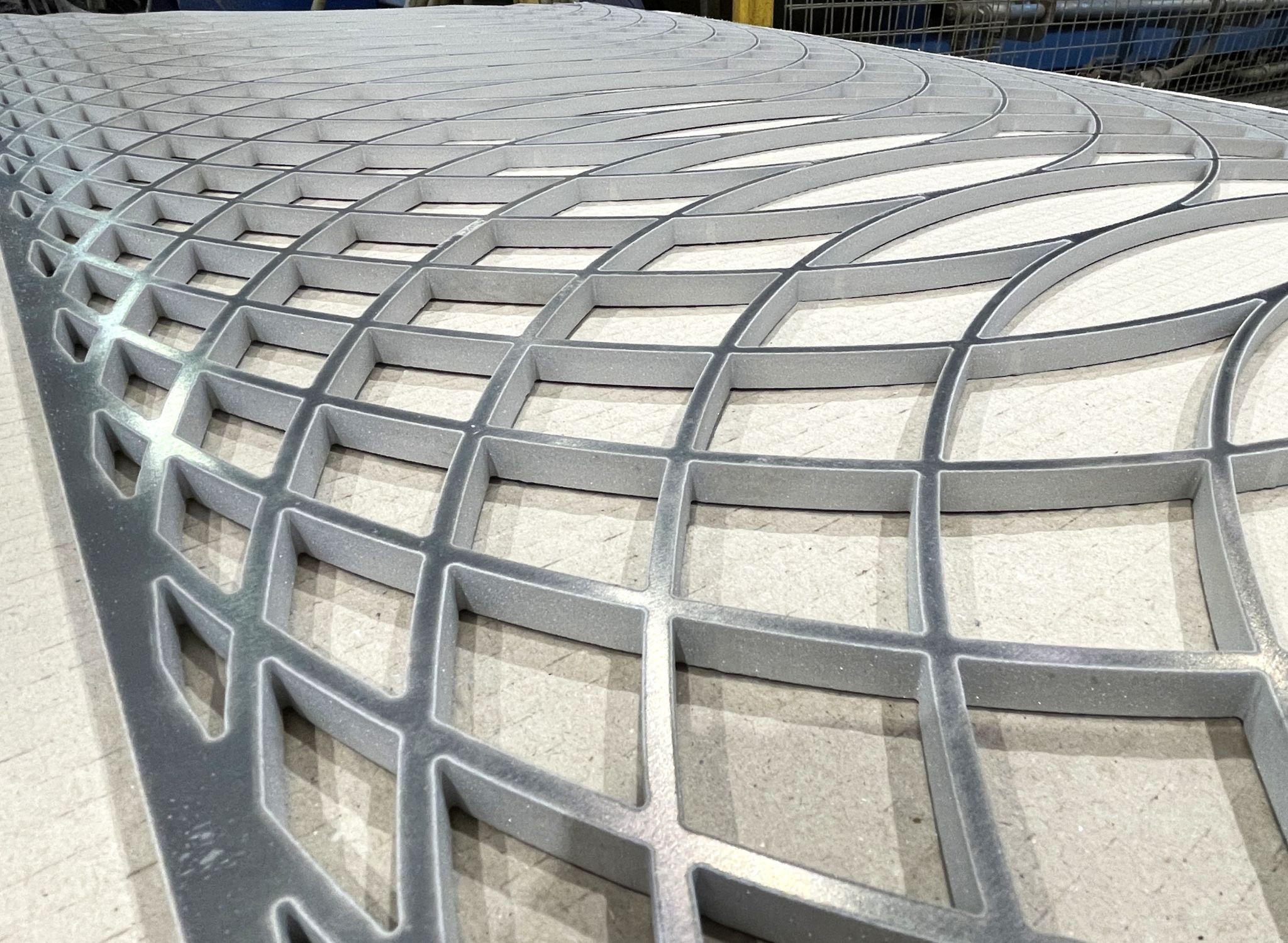

This new addition seamlessly integrates with Charles Day Steels’ existing array of services, including laser cutting, waterjet cutting, bevel cutting, and etching, to offer a comprehensive one-stop shop for metal processing solutions; effectively downstreaming production and enhancing customer experience. The higher tonnage and extended part length capabilities of the new machine allow for the bending of thicker materials across larger dimensions than ever before. Supported by a robust tooling library, Charles Day Steels is well-equipped to handle the most complex part requirements, further establishing our commitment to providing versatile and high-quality solutions to our clients.

This strategic investment is a testament to our commitment to innovation and excellence; complimenting our already impressive array of machinery and services, and further establishing our dominance in the market. With this addition, Charles Day Steels is poised to offer even more competitive pricing, faster turnaround times, and the ability to undertake a broader range of projects, from simple parts to complex, high-precision components.

For more information about our services, or to inquire about how the Bystronic Xpert Pro 320/4100 Press Brake can benefit your next project, please get in touch today.