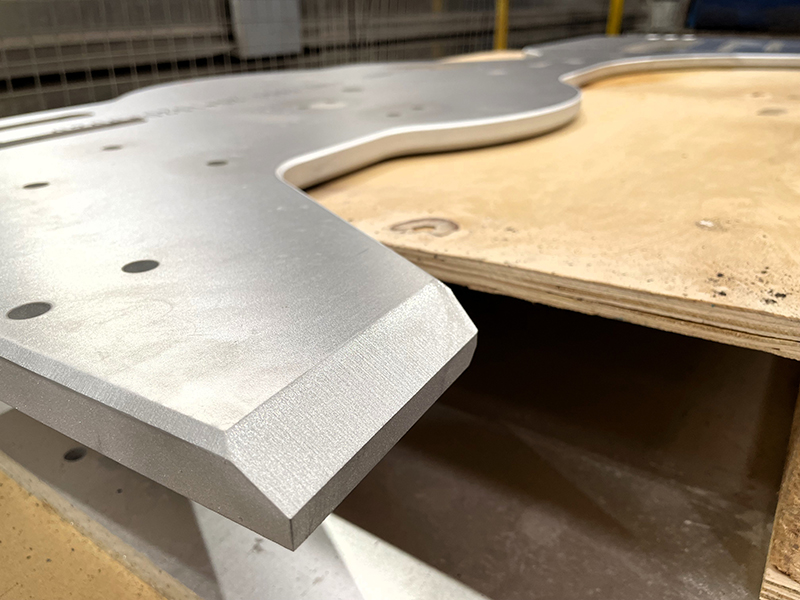

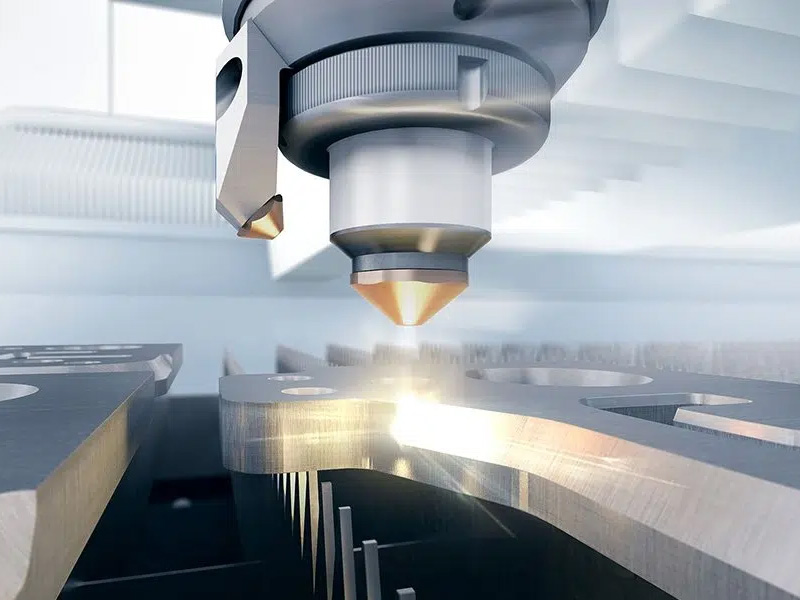

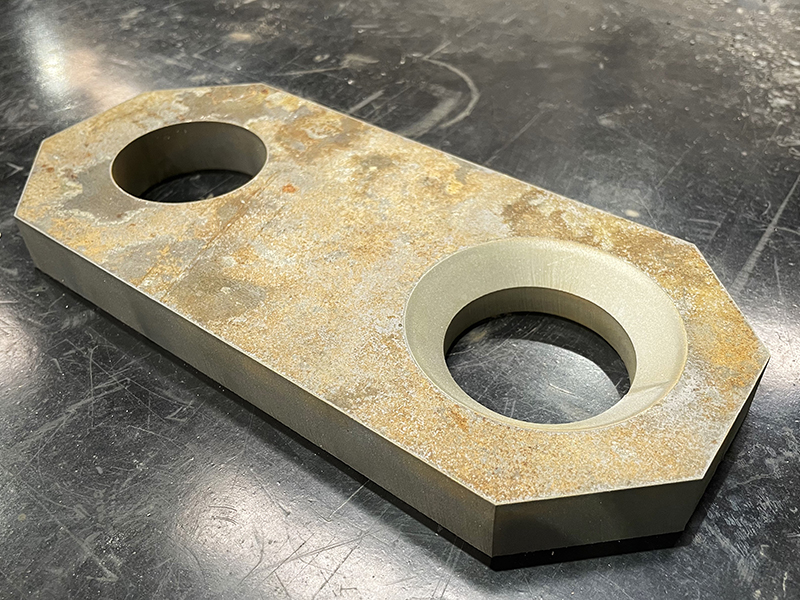

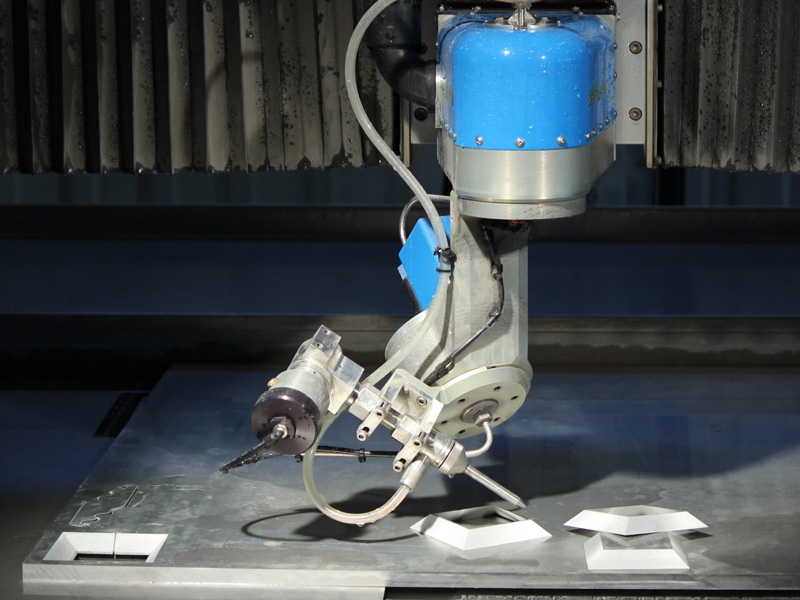

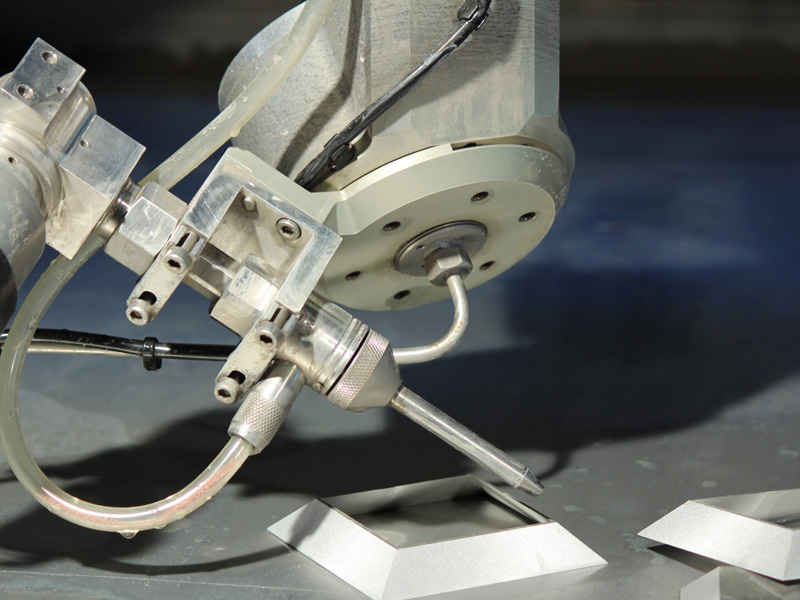

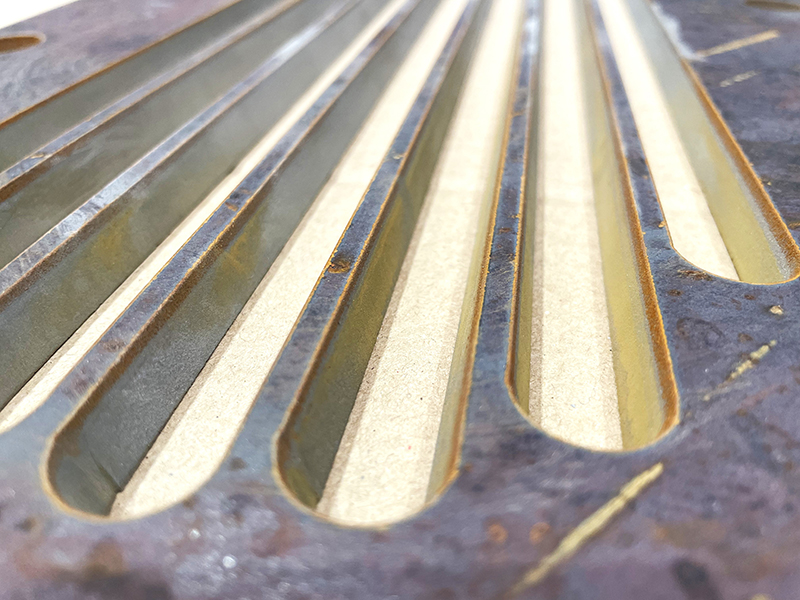

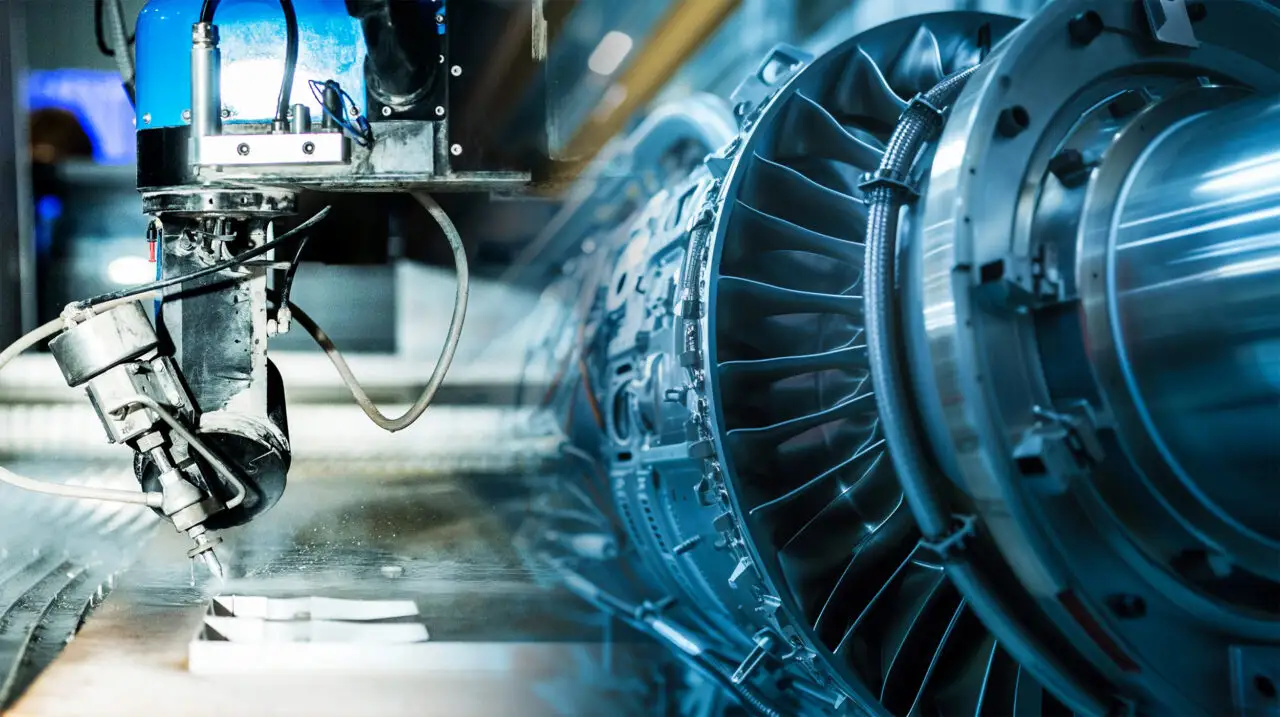

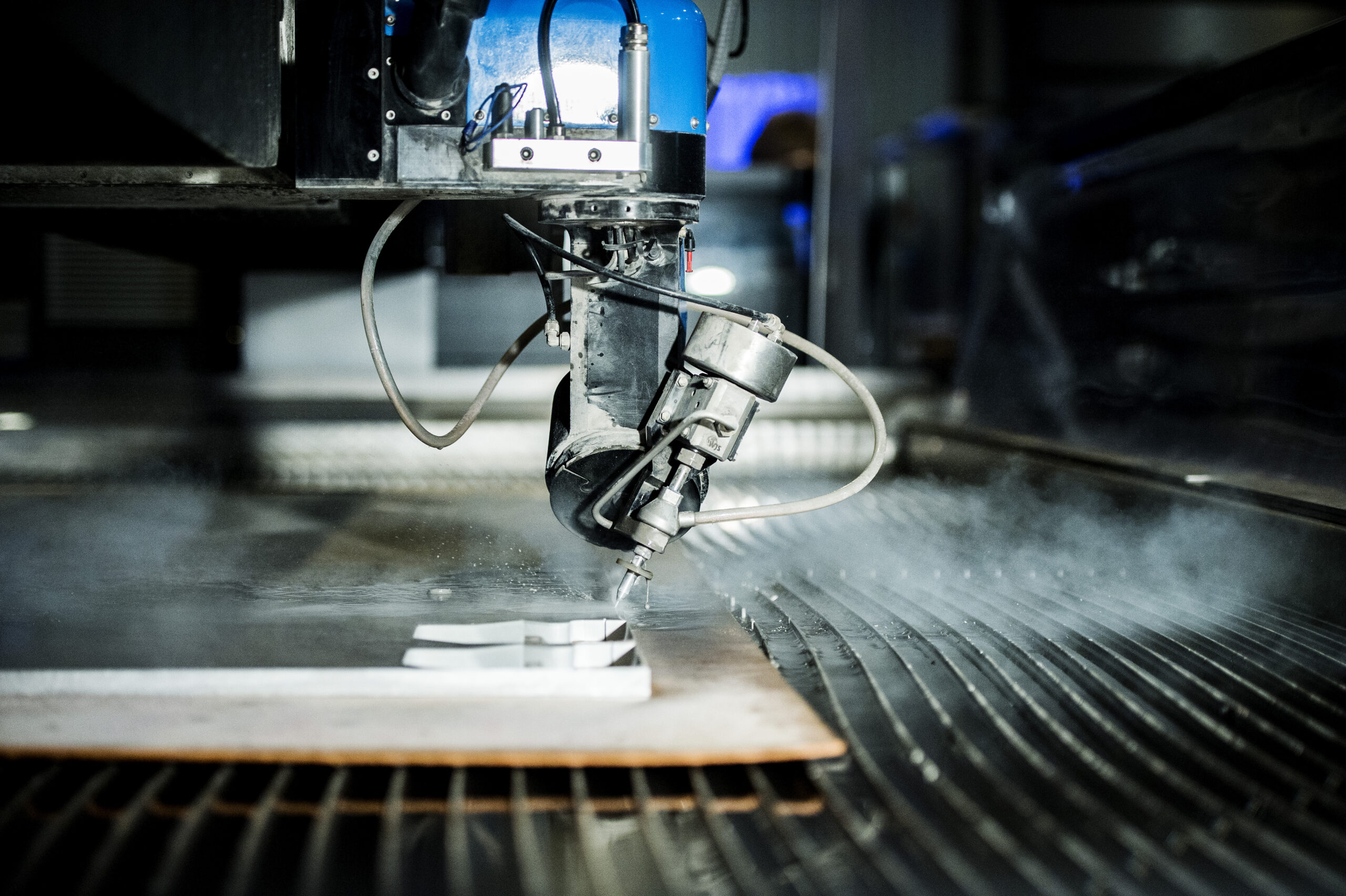

Charles Day Steels are proud to extend our professional profiling services to now include bespoke waterjet bevel cutting, thanks to our revolutionary new machine investment, the Waterjet Sweden Beveljet 60 cutting head and 125hp pump.

Regarded as one of the best and most profound pieces of machinery available in the laser cutting and metal profiling industries, the Waterjet Sweden Beveljet 60 offers unparalleled cutting capabilities that are simply unrivalled by any other profiling specialist in the country.

Charles Day’s Bevel Cutting Services

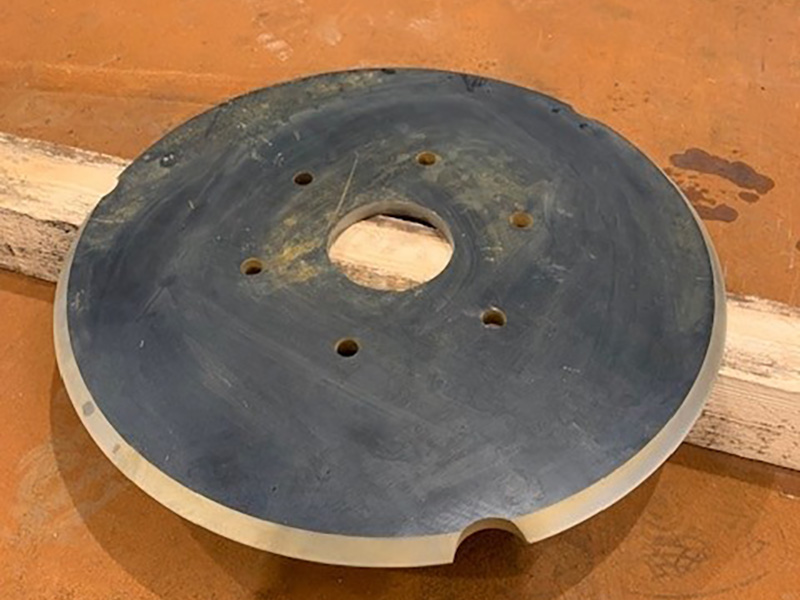

With over 4 decades of professional profile cutting expertise, our latest service addition is our most impressive and advanced yet. With typical waterjet pumps only capable of producing 3,000-4,000 bar of cutting pressure at 50-60hp, our latest addition produces an impressive 6,200 bar pressure at a massive 125hp; a strong addition to our already incomparable level of service.

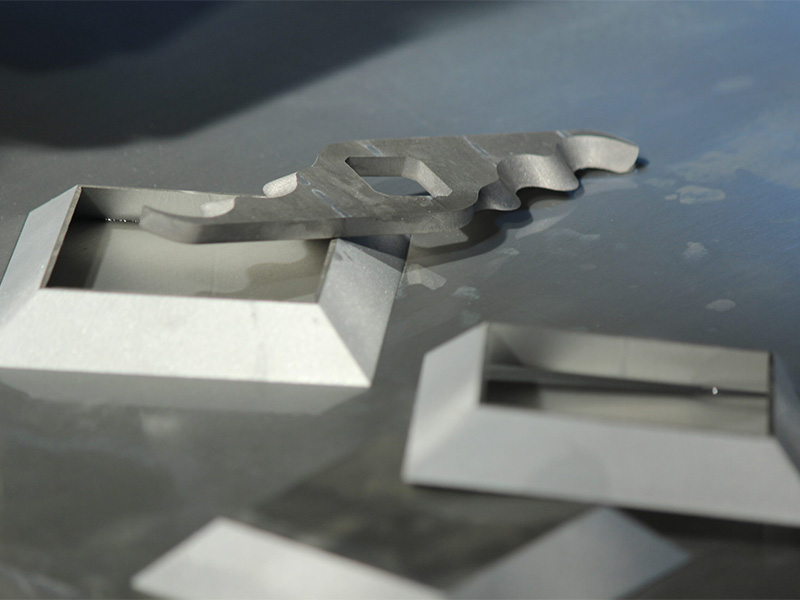

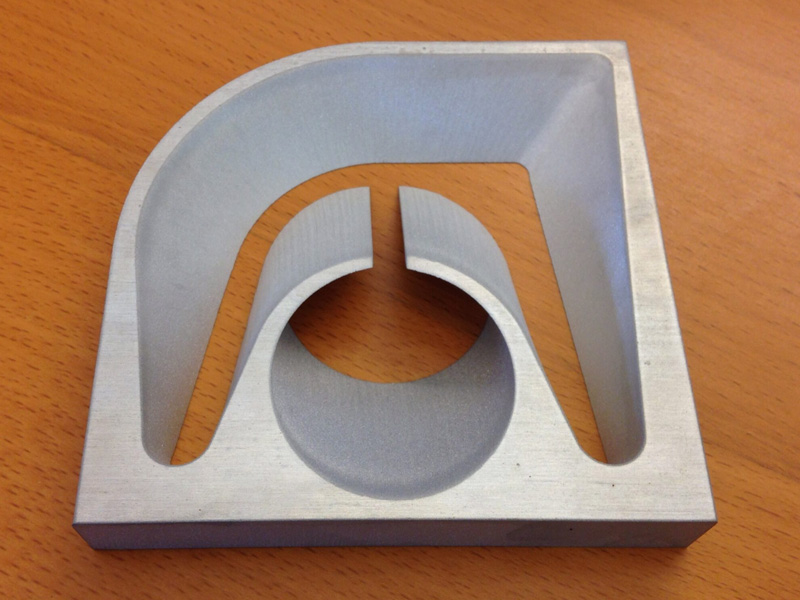

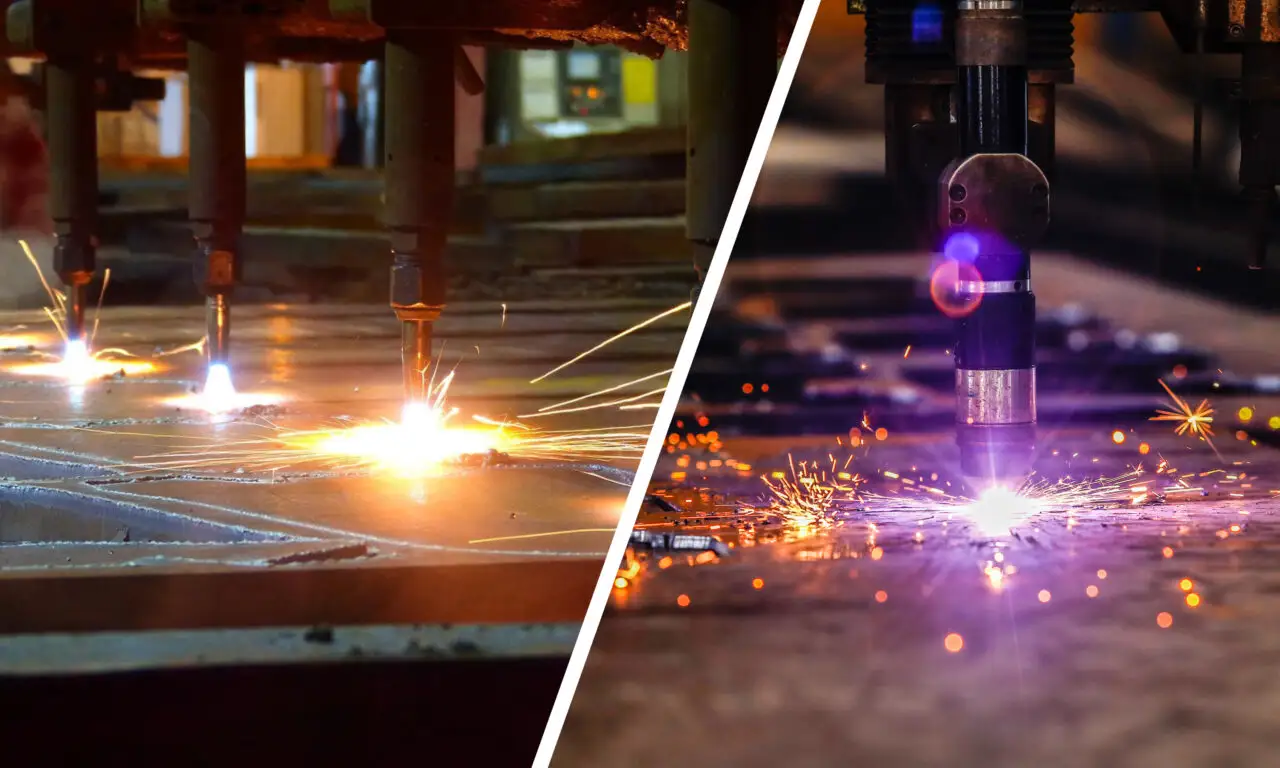

Hosting an unrivalled suite of industry-defining profile cutting machines, including laser, water, flame, and plasma, our newest addition means we are now able to offer 3D bevel cutting. Offering our waterjet cutting service for over 20 years, this newest addition secures our position as market leaders and innovators; providing an impressive turnaround with dramatically increased cut speed, at an extremely competitive price.

Waterjet Bevel Cutting

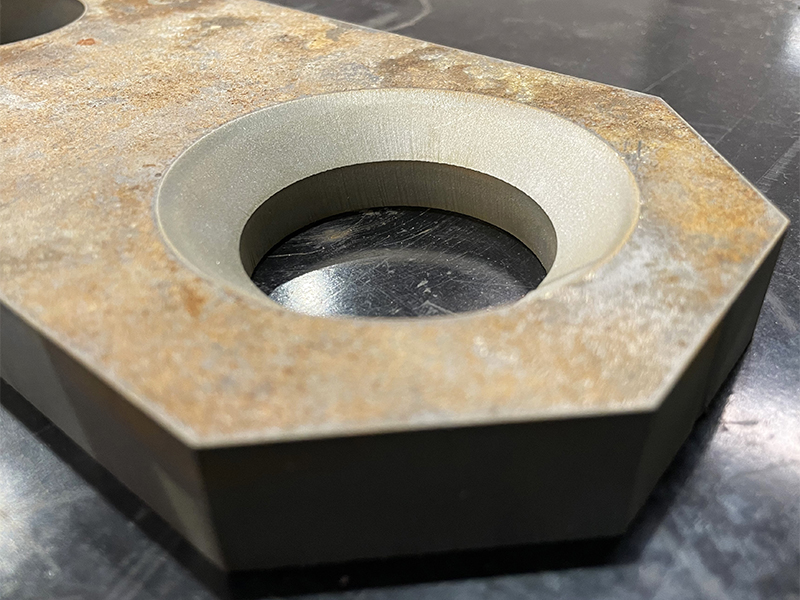

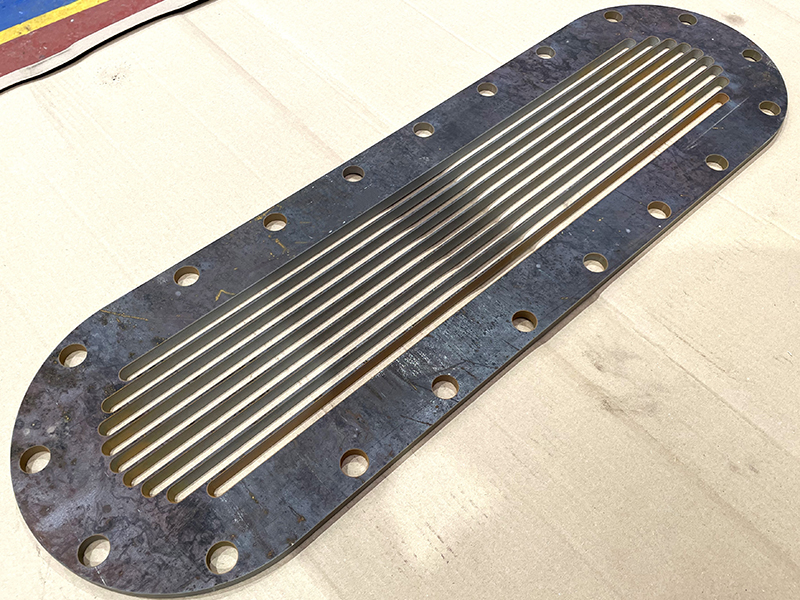

Now with unrivalled water bevel cutting capabilities available in-house, we are able to provide completely accurate and bespoke water bevel cut parts and materials quickly and efficiently, for impressive cost-efficiency that can then be passed down to our customers. With all the capabilities of laser cutting, but with double the capacity, the dual heads on the Waterjet Sweden Beveljet 60 allow for simultaneous cutting.

Benefits of the Waterjet Sweden Beveljet 60

Some of the many benefits of our state-of-the-art waterjet bevel machine investment include…

- Beveljet 60 head allows for 3D parts to be processed up to 60°

- 125hp pump allows for 6200 bar cutting

- Dual heads (3D and 2D) allows for simultaneous cutting of up to 6200 bars of pressure through each head

- Reduced production times

- Adjustable pressure for rapid cutting speed

- Cutting bed measuring 4m x 8.5m

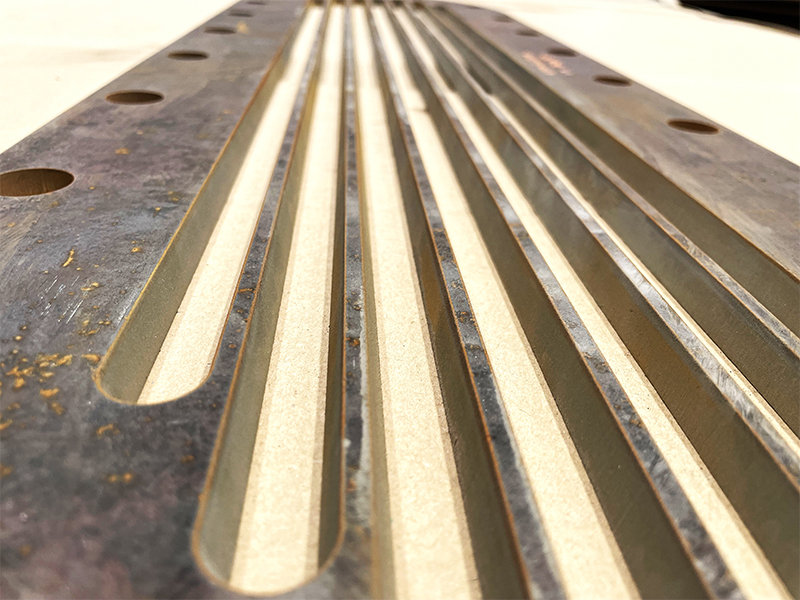

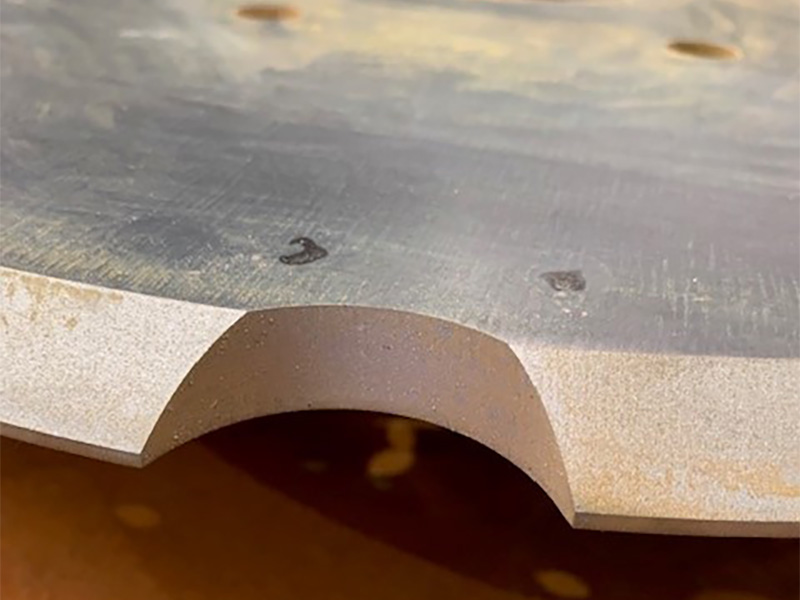

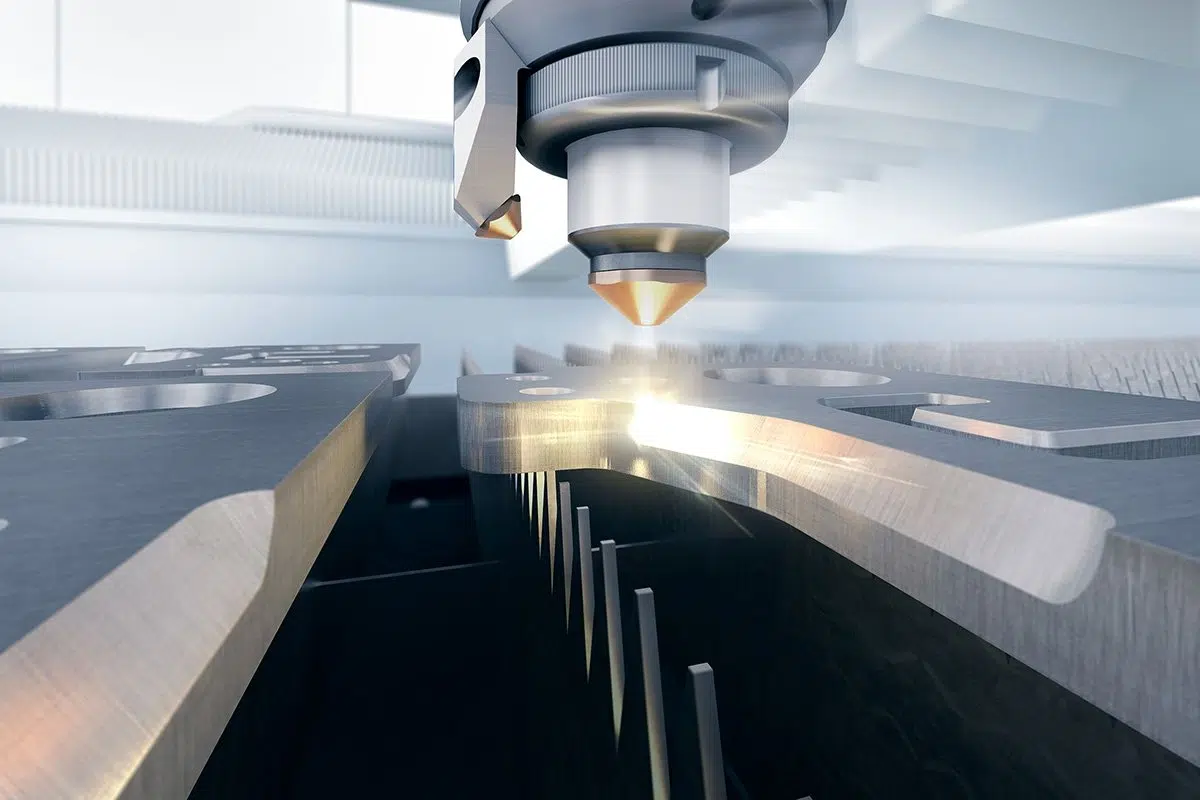

Laser Bevel Cutting

We offer bespoke laser bevel cutting for cost-effective and efficient bevel procurement. Capable of automatically cutting bevels at 45°, our laser cut bevels can be produced in any size on both inner and outer contours.

With our fully-automated laser bevel process, you can rest assured that your laser cut bevels are completely accurate, with zero margins for error. Great for both small and large-volume projects, manual weld preparation can be removed altogether; ensuring a seamless service from start to finish.

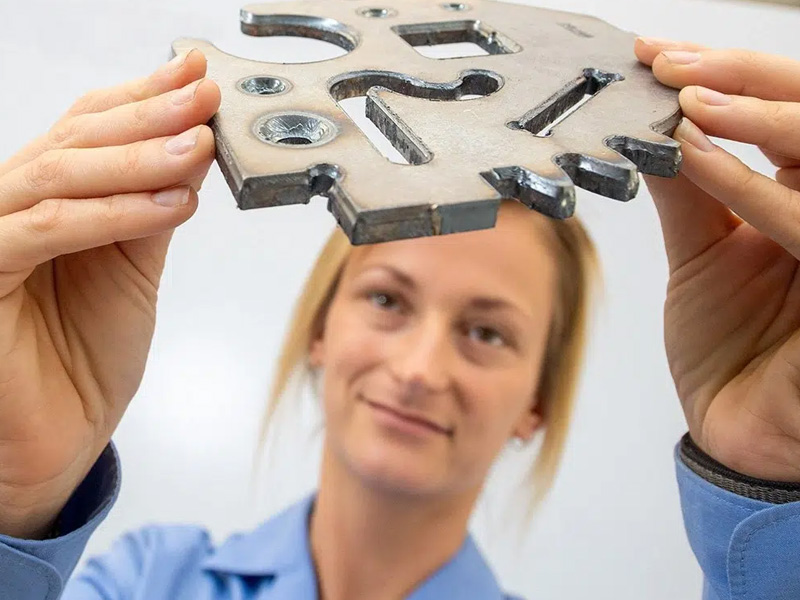

Quality Assurance

Quality. Accuracy. Compliance.

From drawing to delivery, Charles Day take pride in delivering quality profile cutting services to boost downstream efficiency and profitability.

Factory production controls comply with construction product regulation BS EN 1090 EXC4 for intricate cutting of construction and nuclear regulation profiles.

Certified to BS EN ISO 9001:2015 for all profiling requirements.

Bevel Cutting FAQs

What is the difference between a miter and a bevel cut?

A miter cut is a cut that is made at any angle except from 90°, with the blade vertical, whereas a bevel is an angled cut that can be made at any degree apart from 90° with the blade tilted over.

Why is bevel cutting done?

Bevel cutting is utilised for a range of applications, including carpentry, crafting, and welding, and is designed to soften the edge of a piece of material for either aesthetic purposes, safety, joining pieces, creating custom shapes, and increasing weather resistance.

What is the difference between a bevel cut and a chamfer?

Technically speaking, a chamfer is a type of bevel, however, the main difference that distinguishes the two is that a chamfer is an edge designed to connect two surfaces together at a 45° angle, and a bevel’s angle can be anything except 60° or 45°.

What is a compound cut?

A compound cut is the combination of both a miter and a bevel cut and allows for a variety of cutting angles. Exceptional for creating projects that require angled cuts in two separate planes. Compound cuts are typically used for crown moulding and other complex configurations.