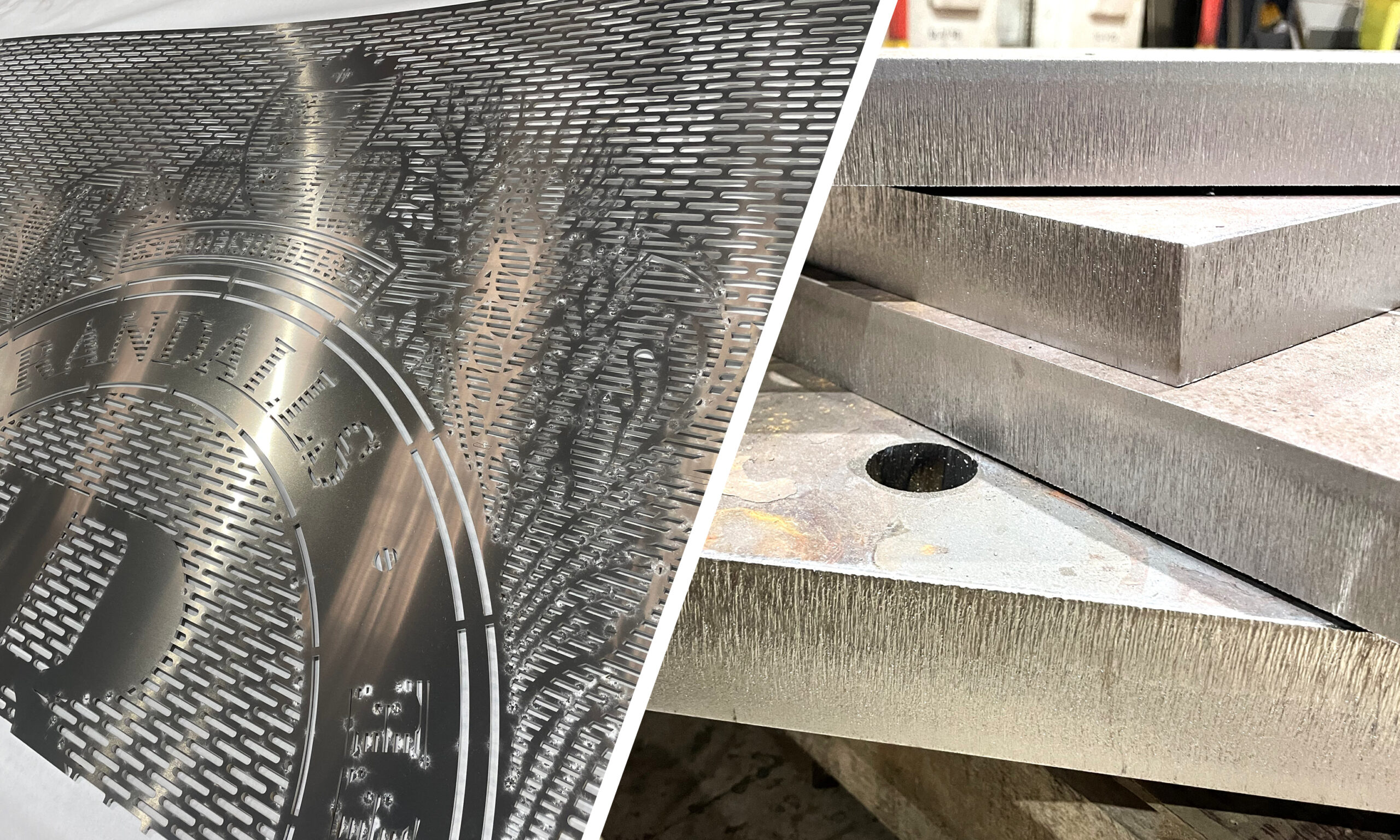

Offering a diverse array of metal profiling capabilities and services, we offer both deburring and vibro-deburring services to save you time and money.

At Charles Day, we take pride in offering professional deburring and vibro-deburring services to help you achieve perfectly finished components. With our expertise and advanced techniques, we can enhance the quality, functionality, and safety of your products by eliminating burrs, rough edges and ridges. With over 4 decades of hands-on experience, you can trust Charles Day to deliver outstanding results and exceed your expectations.

Typically utilised for finishing metal components following cutting, grinding, and turning processes, deburring hosts a range of benefits, and with our in-house capabilities, we aim to reduce the number of steps in the supply chain for your precision metal parts; saving you time and money, whilst never compromising on quality.

Deburring and Vibro-deburring Services

Going beyond aesthetics, removing burrs from cut parts helps to not only provide a quality finish but also helps to improve their longevity and durability; significantly reducing the risk of corrosion and undesired friction. An essential process in finishing cut parts, it’s important that this process is carried out to ensure part functionality long-term.

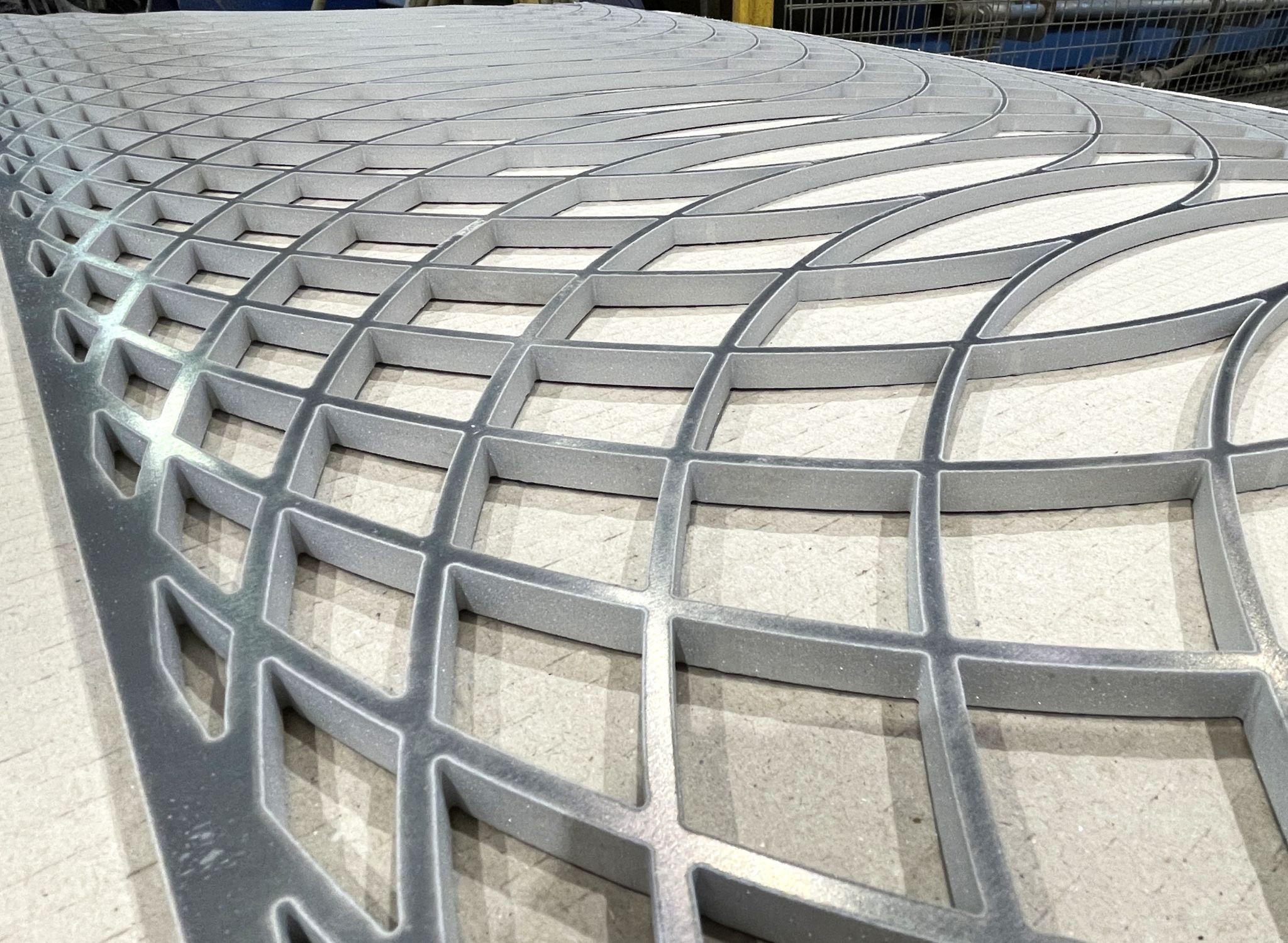

As industry professionals, we understand that every project is different and has different requirements, which is why offer various methods to meet the diverse needs of our customers; our standard deburring, known as centrifugal barrel finishing, is ideally suited to heavy-duty requirements, whereas our vibro-deburring service tends to be suited to large or voluminous parts.

Why Choose Charles Day for Deburring and Vibro-deburring?

Our dedication to exceptional quality is exemplified by our suite of high-spec machinery and extensive tooling libraries, and our commitment to consistent re-investments into only the very best state-of-the-art technology is always at the forefront of our practices; striving to deliver exceptional products in impeccable lead-times and at cost-efficient rates, no matter what.

Unrivalled Capacity

With a host of the latest machinery and state-of-the-art technology available on-site, 24-hour production, cost-effective solutions, and nationwide delivery, we are able to offer industry-defining services without ever compromising on quality.

Exceptional Quality

Charles Day guarantee to deliver a quality product and service every time; giving our customers peace of mind and confidence that their orders will be correct, delivered promptly, and produced to the very highest industry standards.

Extensive Experience

Established in 1976, we are proud to boast over 40 years of direct industry experience. Our extensive experience and expertise are always at the forefront of our practices, and inform every stage of your production process.

Deburring FAQs

What is a burr?

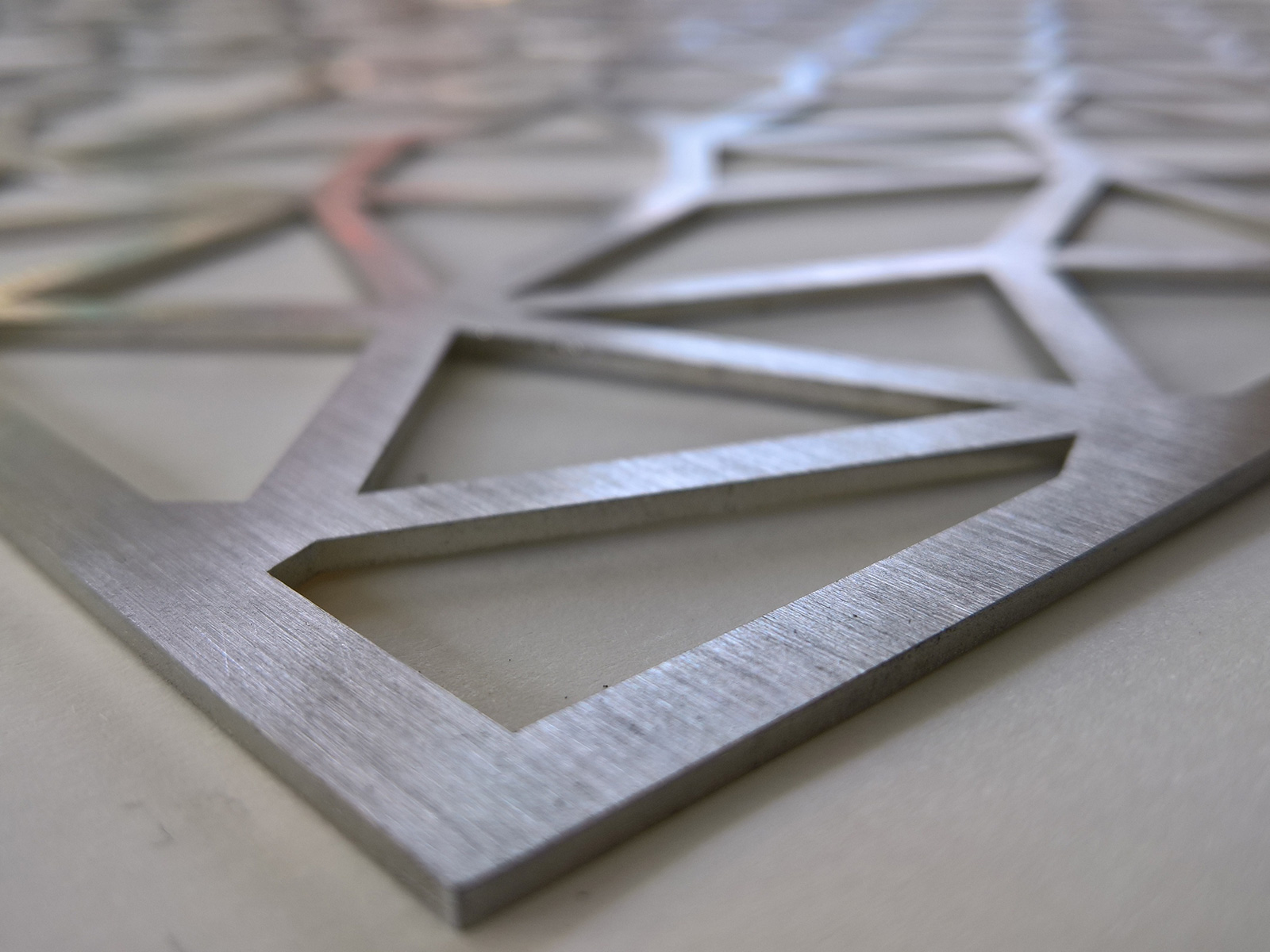

A burr is a raised or rough edge that is still attached to a workpiece, such as sheet metal, after modifications such as cutting, grinding, and turning. They are typically removed with a deburring tool to improve part efficiency, safety and longevity.

What is deburring?

Deburring is the process of removing ridges, rough edges, and excess material left on the edge of a cut part after material processing.

What is vibratory deburring?

Vibratory deburring, or vibro-deburring, removes rough edges and ridges from cut parts by placing them inside a vibratory chamber with polishing chips where they are vibrated; causing the polishing chips to rub against the workpieces – effectively removing excess material.

Why is deburring important?

Deburring your cut parts is extremely important, as by removing excess material, rough ridges and edges from your workpieces, you can significantly reduce friction between your workpieces and machines, improve longevity and durability, simplify operation, and improve the aesthetic of the machines themselves.

Contact our Team of Professionals

For professional metal profiling services, get in touch with our team of professionals today.

Quality Assurance

Quality. Accuracy. Compliance.

From drawing to delivery, Charles Day take pride in delivering quality profile cutting services to boost downstream efficiency and profitability.

Factory production controls comply with construction product regulation BS EN 1090 EXC4 for intricate cutting of construction and nuclear regulation profiles.

Certified to BS EN ISO 9001:2015 for all profiling requirements.