High-Quality Sheet Metal Pressing & Profiling

Here at Charles Day, we take immense pride in our range of expert metal profiling services, and always go above and beyond to develop innovative new solutions to solve even the most complex or intricate of metal profiling requests.

With over 4 decades of industry experience, our team of profile bending and pressing professionals are committed to providing an exceptional product every time, and always goes above and beyond to provide unique and efficient solutions that save you both time and money.

Innovative Profile Bending & Sheet Metal Pressing Solutions

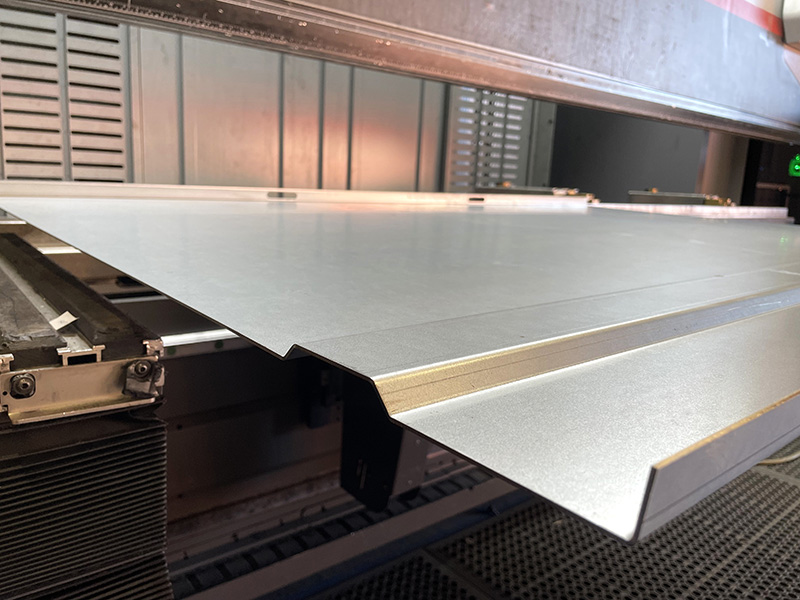

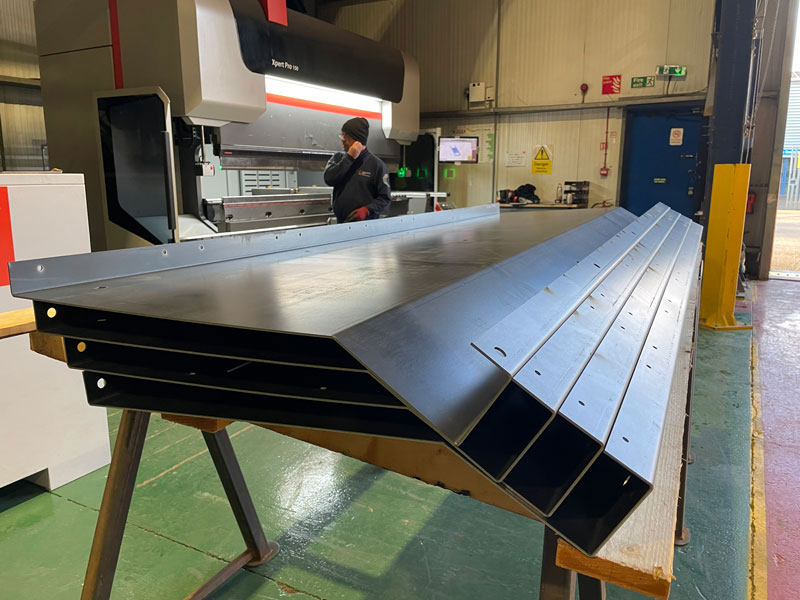

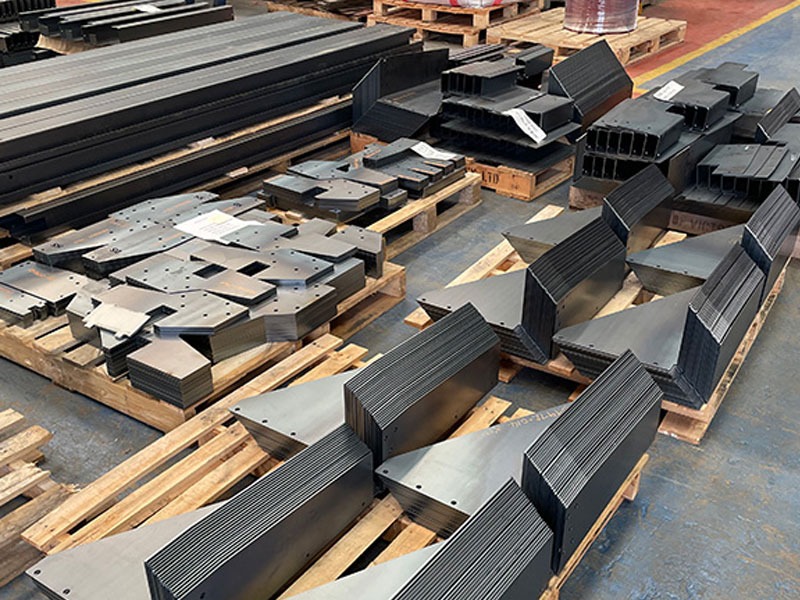

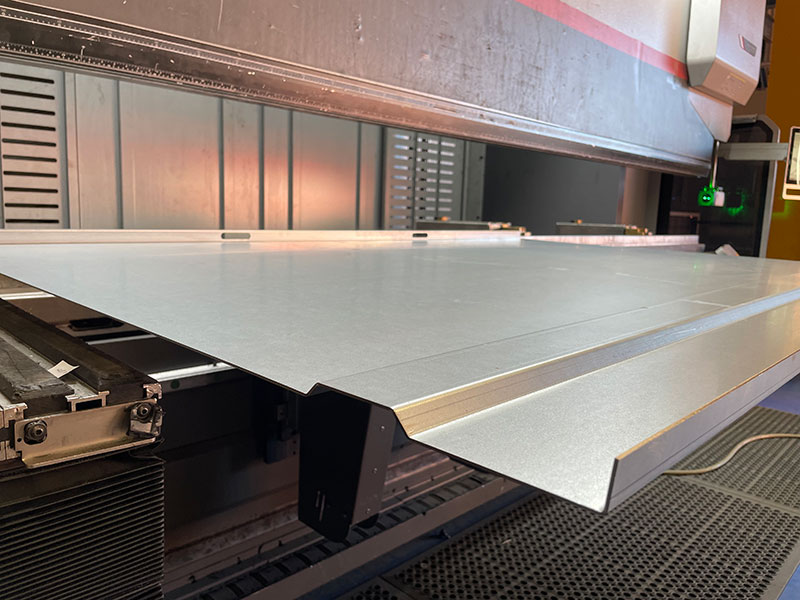

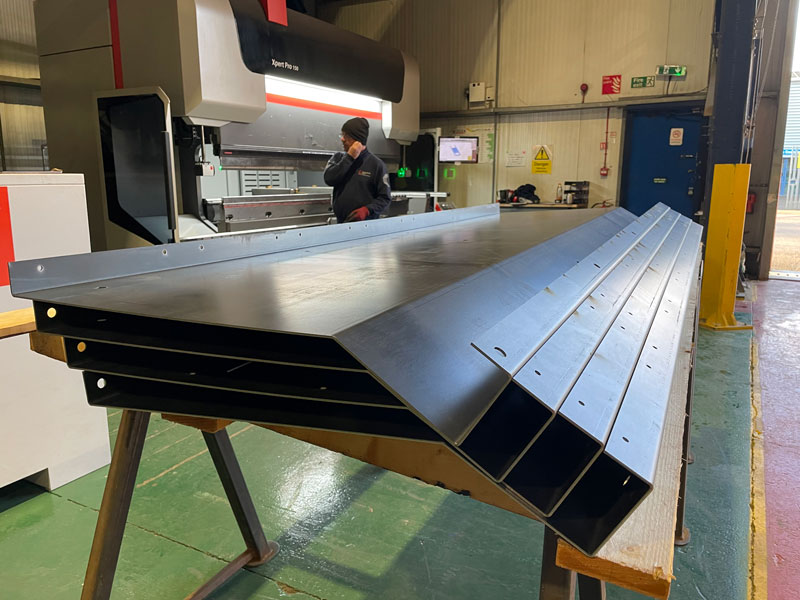

With in-house facilities for profile bending and sheet metal pressing, the team at Charles Day, as well as sister company The Laser Cutting Co., are able to meet a range of project and material requirements, and with state-of-the-art press brake machines on site, turnaround is fast, and quality is always superior. Whether your material of choice is mild or stainless steel, aluminium, or something different, we here at Charles Day are able to profile and press materials to the very highest quality and capabilities.

Why Choose Charles Day For Profile Bending & Sheet Metal Pressing?

Versatile Capability

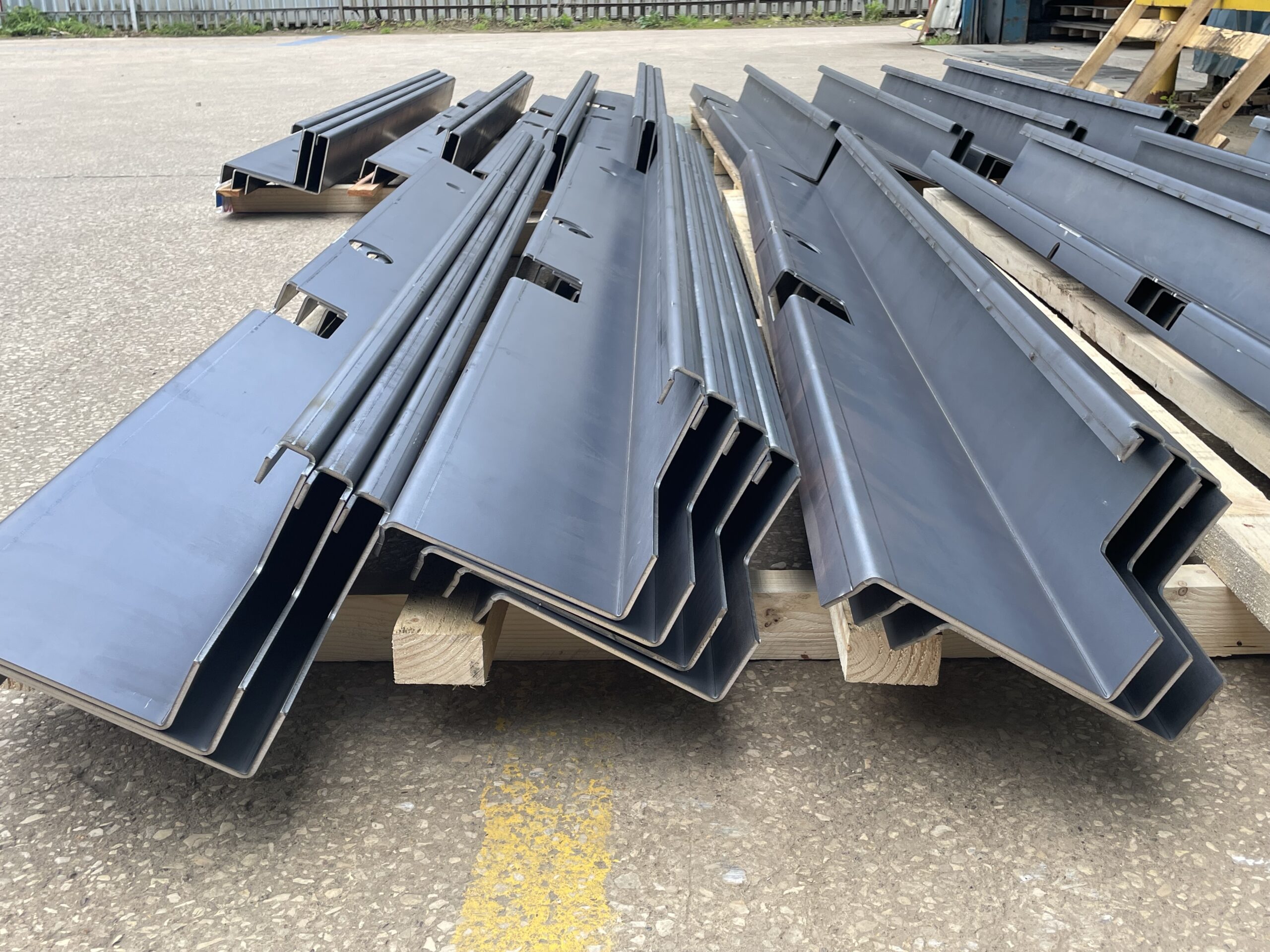

Having a range of machinery, complimented by extensive tooling libraries, allows for stress-free procurement – even on the most complex of projects. Capable of pressing parts up to 3100mm (and 4000mm+ via our trusted partner network), Charles Days makes sense for your pressed components.

In-House Programming

With a dedicated CAD team and technology on-site, we use the latest software to support you at the early design stage and ensure your parts are correct, accurate, and on time.

One Stop Shop

From sourcing material at competitive prices, cutting and bending, through to on-time delivery, we make procuring parts and materials for your project easy.

Robust Partner Network

For those more challenging projects and bends, whether they be heavy-duty or complex, we work closely with our trusted partner suppliers to ensure the highest levels of quality and reliability on even the most demanding of projects.

Contact our experienced sales team

Let Charles Day help lower your costs.

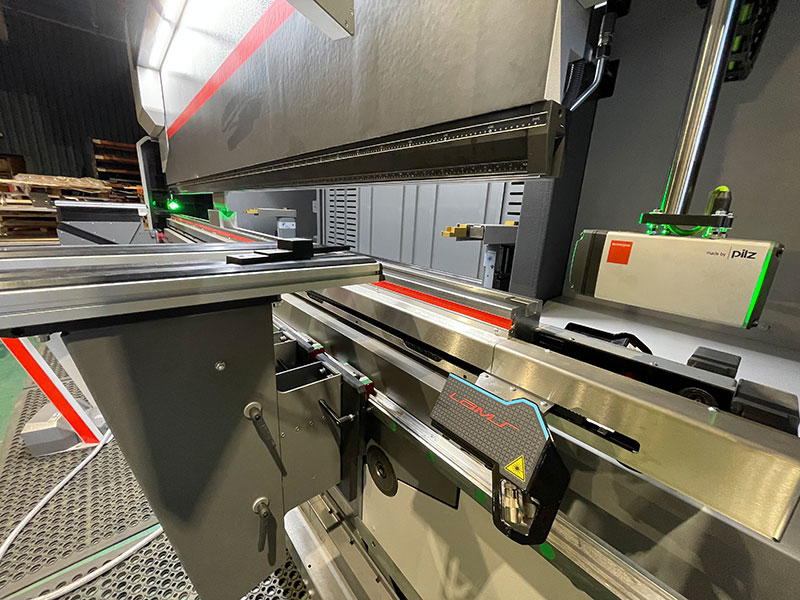

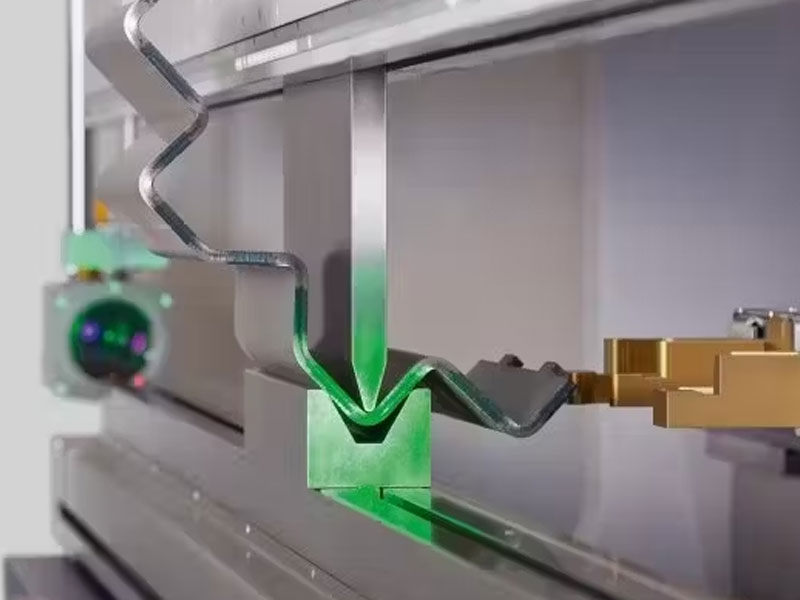

Bystronic Xpert Pro 150/3100

Tonnage: 150

Bending Length: 3100mm

Open Height: 840mm

Max Work Speed: 32mm/s

Bystronic Xpert 40

Tonnage: 40t

Bending Length: 1030mm

Open Height: 570mm

Max. working speed: 25mm/s

Bystronic Xpert Pro 320/4300

Tonnage: 320t

Bending Length: 4300mm

Open Height: 640mm

Max. working speed: 650mm/s

Quality Assurance

Quality. Accuracy. Compliance.

From drawing to delivery, Charles Day take pride in delivering quality profile cutting services to boost downstream efficiency and profitability.

Factory production controls comply with construction product regulation BS EN 1090 EXC4 for intricate cutting of construction and nuclear regulation profiles.

Certified to BS EN ISO 9001:2015 for all profiling requirements.

FAQs

What is profile bending?

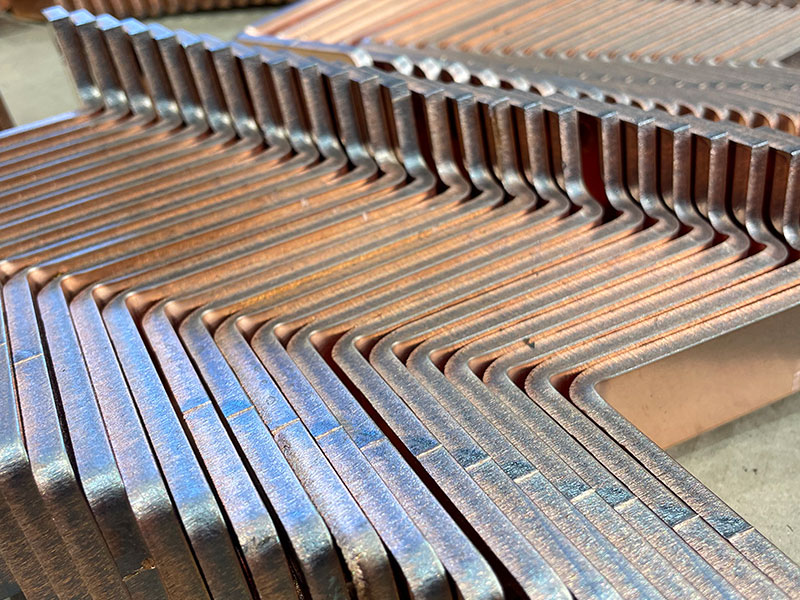

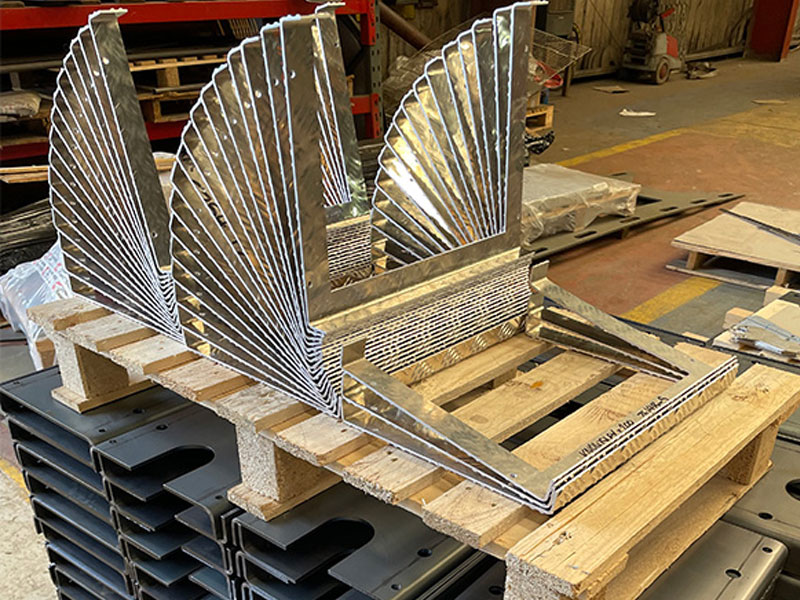

Profile bending, also known as section bending, is a metal forming process that creates curvature or bends in the cross-sectional profile of a metal piece. This process can be applied to various shapes, including angles, bars, beams, channels, and tubes, using our series of professional profile bending and pressing machines.

What is pressing in metalworking?

Pressing in metalworking refers to a process where force is applied to a workpiece to alter its shape without adding or removing material. This is achieved through the use of our press machines, which can perform operations such as punching, embossing, bending, and forming on metal sheets or plates.

What materials can be processed with profile bending and pressing?

Here at Charles Day Steels, our in-house capabilities mean we can process a wide range of materials, including aluminium, stainless steel, carbon steel, copper, and brass. The choice of material depends on the required strength, flexibility, and application of the finished product.

What industries use profile bending and pressing?

Profile bending and pressing processes are vital in numerous industries, such as construction, automotive, aerospace, shipbuilding, machinery manufacturing, and architectural applications. They are used to produce parts for structures, vehicles, machinery, and decorative elements.

What are the advantages of profile bending?

Profile bending by Charles Day Steels offers several advantages, including the ability to create complex shapes and curves, high precision and consistency in production, and the possibility of processing a variety of profile shapes and sizes. It also allows for the efficient use of materials and can enhance the structural integrity of the bent profiles.

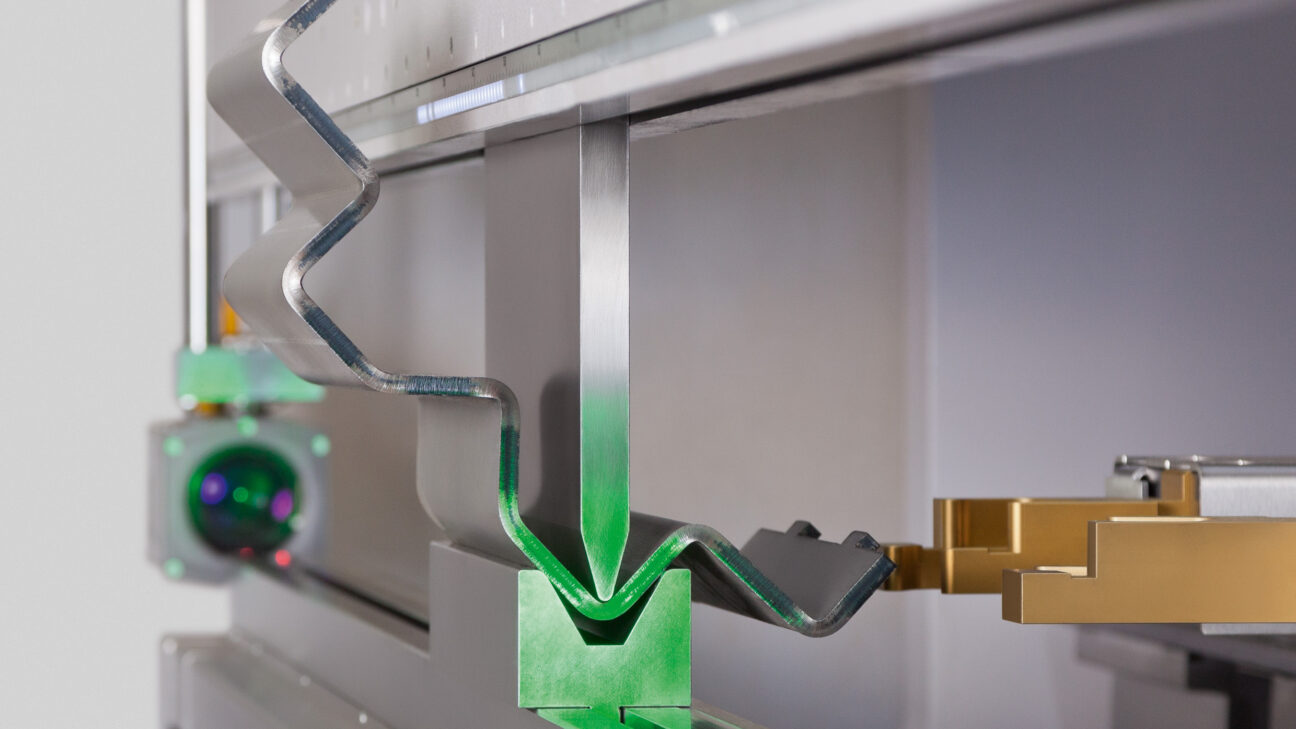

How does the metal pressing process work?

Pressing involves placing a metal sheet or plate between a punch and a die set within a press machine. When the press is activated, the punch moves towards the die, applying pressure that deforms the metal into the desired shape. The specific operation (e.g., bending, punching) depends on the die and punch shapes.

Can profile bending and pressing be automated?

Yes, both processes can be automated to increase production speed, improve precision, and reduce labour costs. Automated systems can be programmed to perform repetitive tasks with minimal human intervention, ensuring consistent quality and higher productivity.

How is quality ensured during profile bending and pressing?

At Charles Day Steels, quality is ensured through proper machine setup, regular maintenance, the use of precision tooling, and adherence to operating parameters suited to the material and desired outcome. Additionally, inspection procedures, such as visual inspection and dimensional checks, are applied throughout the production process and maintained through out ISO 9001 Quality Accrediation.

Where can I find services for profile bending and pressing?

Services for profile bending and pressing can be found through specialised metalworking and fabrication companies. Here at Charles Day Steels, we offer the right expertise, equipment, and capacity to meet the specific requirements of your project, with a bending width of up to 4300mm and 320 tonnes, theres very little we can’t achieve.

How is the bending radius determined?

The bending radius is determined based on the material’s properties, the cross-sectional shape of the profile, and the desired final shape. Factors such as material thickness, width, and the type of bend (e.g. tight radius vs. large radius) also play a crucial role in determining the bending radius.