Charles Day (Steels) Ltd was established in 1976 providing a flame cutting service. From that date, Charles Day has evolved into one of the largest and most diverse specialist profile cutting companies in the UK.

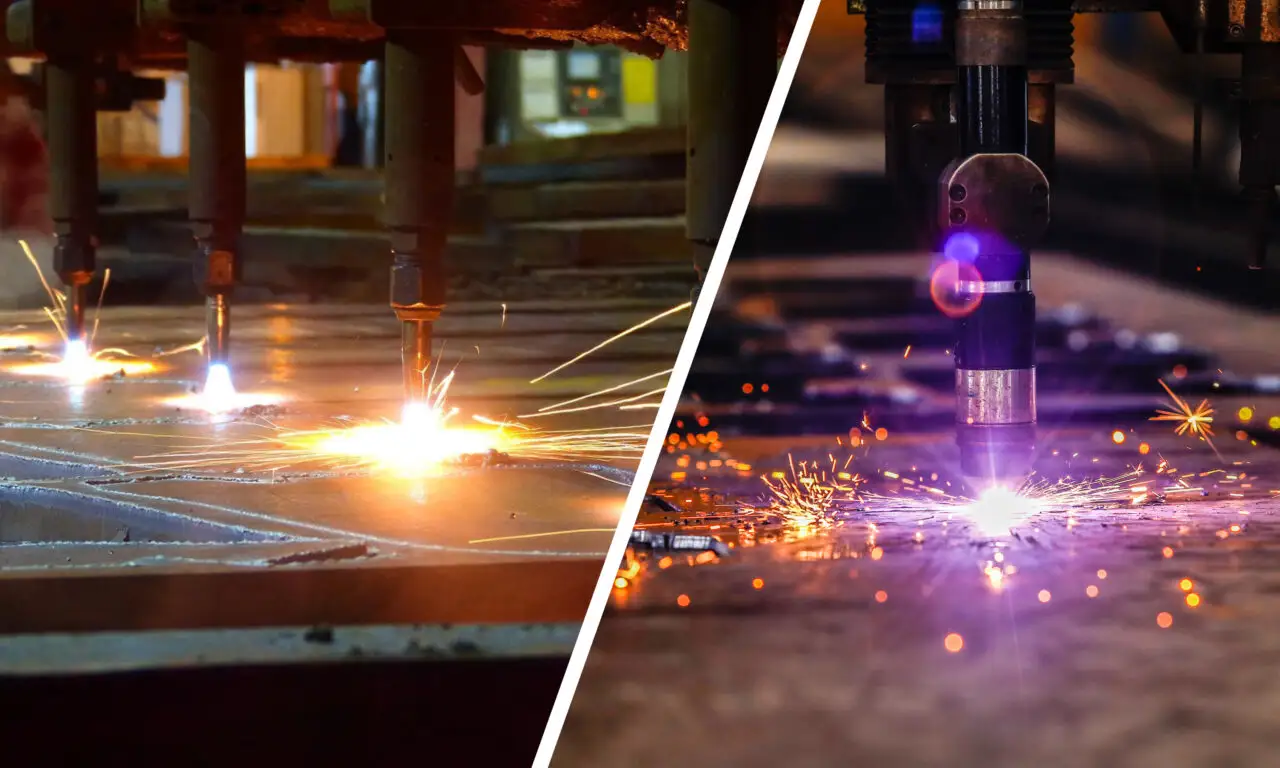

Experts in Laser, Flame, Waterjet and Plasma

Based in the city of steel, we operate from premises minutes away from the birthplace of stainless steel and we now offer not only flame cutting but plasma, waterjet and laser cutting.

We continue to invest in the latest cutting technology to provide our customers with the best quality profile cut parts.

In addition to our portfolio of cutting and profiling services our sister company, The Laser Cutting Co Ltd also boasts an offering of four dedicated tube, box, angle and channel laser cutting systems.

Quality Assurance

Quality. Accuracy. Compliance.

From drawing to delivery, Charles Day take pride in delivering quality profile cutting services to boost downstream efficiency and profitability.

Factory production controls comply with construction product regulation BS EN 1090 EXC4 for intricate cutting of construction and nuclear regulation profiles.

Certified to BS EN ISO 9001:2015 for all profiling requirements.

Profiling Expertise

Founded in 1976 as a flame profiling service, over the next 3 decades we have expanded our services portfolio to include laser, waterjet and plasma while still retaining our flame cutting capabilities. In turn, this has enabled us to establish ourselves as one of the largest and most diverse specialist profile cutting companies in the UK.

Diverse Cutting Methods

We’re proud to be one of the few profiling companies able to offer 4 different cutting methods under the same roof. This enables our customers to have a choice of 4 different cutting methods, enabling them to find and utilise a service perfectly fitted to their requirement. It also allows us to offer alternative profiling methods which may be more cost effective for our clients.

CE Marking (BS EN 1090-1)

The construction industry forms a large part of our customer base and so we understand the importance of being able to provide CE Marked profiled parts. Due to this, Charles Day underwent extensive auditing and now have a Factory Process Control system in place for the laser/flame/plasma cutting of CE Marked materials due to be used within the construction industry.

Large, Purpose-Built Facilities

Our 40,000 square foot purpose built faculties are large enough to house all our profiling machines under one roof. This puts us in the position to handle almost any requirement regardless of size, quantity and cutting methods required.

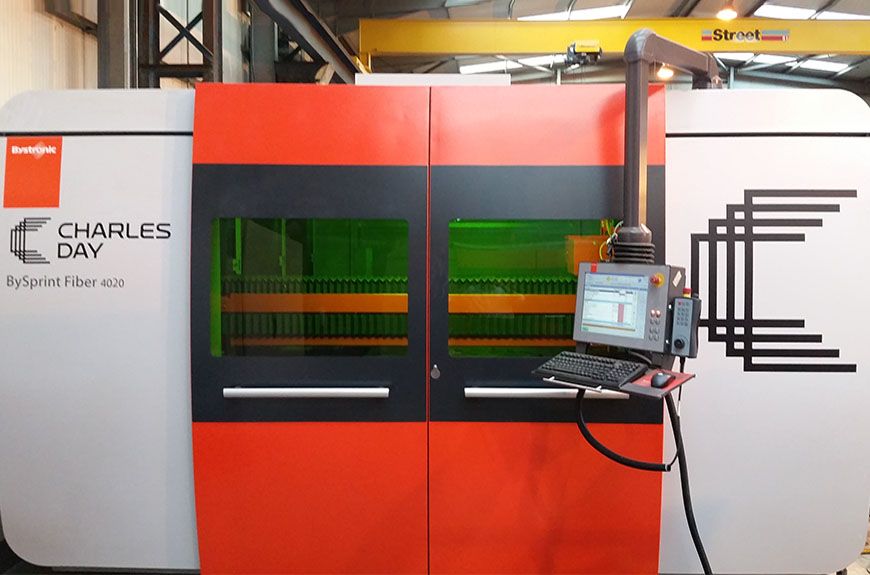

State-of-The-Art Machines

We know that our customers expect the best possible product and so we continually invest in the latest cutting technology to provide our customers with the highest quality profile cut parts.

24hrs, 7 Days a Week Cutting

Our CNC driven cutting methods and automation system allows us to provide “lights-out” production. With our machines cutting around the clock, our clients get a more cost effective service and reduced lead times.

ISO9001:2015 Accredited

We are accredited to ISO 9001:2015 and strive to provide our customers with a quality service. Our accreditation ensures that we meet the needs of our customers. We’ve had ISO9001 accreditation for over 14 years, longer than most of our competitors have been in business!

EU Metal

We always strive to use metals sourced from within the European Union due to the higher quality and more consistency of the product. However dependant on the material and requirement, this may not always be possible

Large Stock Levels

We keep a wide range of different metals in a range of sizes and thicknesses in stock. However, if we don’t have a particular material in stock, we can usually source it within 24-48 hours.

CAD Software

Possessing the latest CAD systems and CNC technology, we can guarantee a high precision profile regardless of the complexity of the requirement.

Nationwide Delivery

We know how important it is for our clients to receive their goods on time, therefore we strive to provide a quality, on-time delivery service for our clients throughout the UK. With our own fleet of vehicles plus close working relationships with third-party couriers we aim to ensure that every order arrives where it should, when it should.

Regardless of your requirement, if you need something cut, we can help.

Our various different cutting methods allows us to profile virtually any material in thicknesses up to 230mm.

Through our considerable and continual investment in new technology, Charles Day can effortlessly fulfil each of these services for customers. In addition to this, we can also arrange such services as Flattening, Shot-blasting, Rumbling, Bending, Surface Grinding, Heat Treatment, Machining, Drilling and Fabrication.