Aluminium Cutting Services: Proficient and Dependable Profiling

Traditionally a difficult metal to laser cut, our 10kW, 15kW, and 20kW fibre lasers can easily profile aluminium and aluminium alloys up to 40mm thick. Our high-quality sub-contract aluminium laser cutting services provide exceptional part output and precision. Due to the reflective nature of aluminium, it is difficult to cut on traditional CO2 lasers. Profiling aluminium on our fleet of 6 Fibre laser machines is not only quicker but also considerably cheaper.

What sets aluminium apart from other materials is its high corrosion resistance and high strength compared to its weight. For these reasons we have been cutting aluminium for a range of industries including aircraft design and building, boat building and construction industries, to name a few. Trailing behind iron, aluminium is now the world’s second most widely used metal.

We keep a number of aluminium sheets and thicknesses in stock, if we don’t have the specific material you require, we can usually source it within 24-48 hours. We’re also happy to cut your free-issue material if required.

For aluminium plates from 0.1mm to 40mm thick, we recommend our fibre lasers, for materials thicker than this up to 230mm we suggest using our waterjet cutting service.

Why Trust Charles Day Steels for Aluminium Cutting?

As one of the UK’s leading metal profiling companies, we take immense pride in having some of the best aluminium cutting facilities available in the industry. With a commitment to continuous self-reinvestment and fully informed by over four decades of metal profiling expertise, our comprehensive range of in-house metal profiling services means we always exceed expectations; providing our customers with an efficient, dependable, and professional service every time.

Our dedication to quality assurance, diverse cutting and profiling capabilities, 24-hour production, extensive range of metals in varying sizes and thicknesses, and competitive pricing collectively demonstrate our commitment to excellence.

Benefits of Laser Cut Aluminium by Charles Day Steels

Laser cutting aluminium steel offers a diverse array of benefits, from cost-effectiveness to versatility, aluminium cutting is the preferred material across various industries for its robust nature and light weight. Some of the key advantages of laser cut aluminium include:

Precision Cutting

Aluminium is known for its excellent thermal conductivity, which helps in dissipating heat quickly during laser cutting. This property enables precise cuts with minimal distortion, resulting in high-quality finished products.

Versatility

Aluminium can be easily cut with lasers, regardless of its thickness or alloy composition. This versatility makes it suitable for a wide range of applications across various industries, from aerospace to automotive to electronics.

No Surface Contact

Laser cutting is a non-contact process, meaning the material being cut is not physically touched by cutting tools. This characteristic is particularly advantageous for aluminium, as it minimises the risk of surface damage and contamination.

Clean Cutting Edge

Laser cutting produces clean and smooth edges without the need for secondary finishing processes. This reduces post-processing time and labour costs, making it an efficient manufacturing solution for aluminium parts and components.

Complex Shapes

Laser cutting allows for the fabrication of intricate and complex shapes with high precision. This capability is especially valuable for industries that require intricate designs or custom components.

Cost-Effectiveness

Laser cutting offers cost advantages for aluminium processing compared to traditional methods like milling or punching. It requires minimal setup time, reduces material waste, and can be automated for mass production, leading to overall cost savings.

Typical Aluminium Cutting Applications

Due to its versatility, aluminium can be used for a huge range of applications spanning various industries. Some aluminium cutting applications include, but are not limited to:

Ship Building

Architectural/Civil Engineering

(street furniture, structural sections, decorative panels)

Automotive

(vehicle bodies, trailers, truck frames)

Road Signs

Hospitality

(Food industry containers)

Construction

(window frames, doors, curtain walls, and structural components)

Aerospace

(aircraft frames, fuselages, wings, and various structural components)

Electronics

(electronic enclosures, heat sinks, and components due to their conductivity and corrosion resistance)

Marine Structures

(boat hulls, masts)

Sheet Metal Laser Cutting Thicknesses

Laser Material Thickness

Laser Cut Thickness (mm)

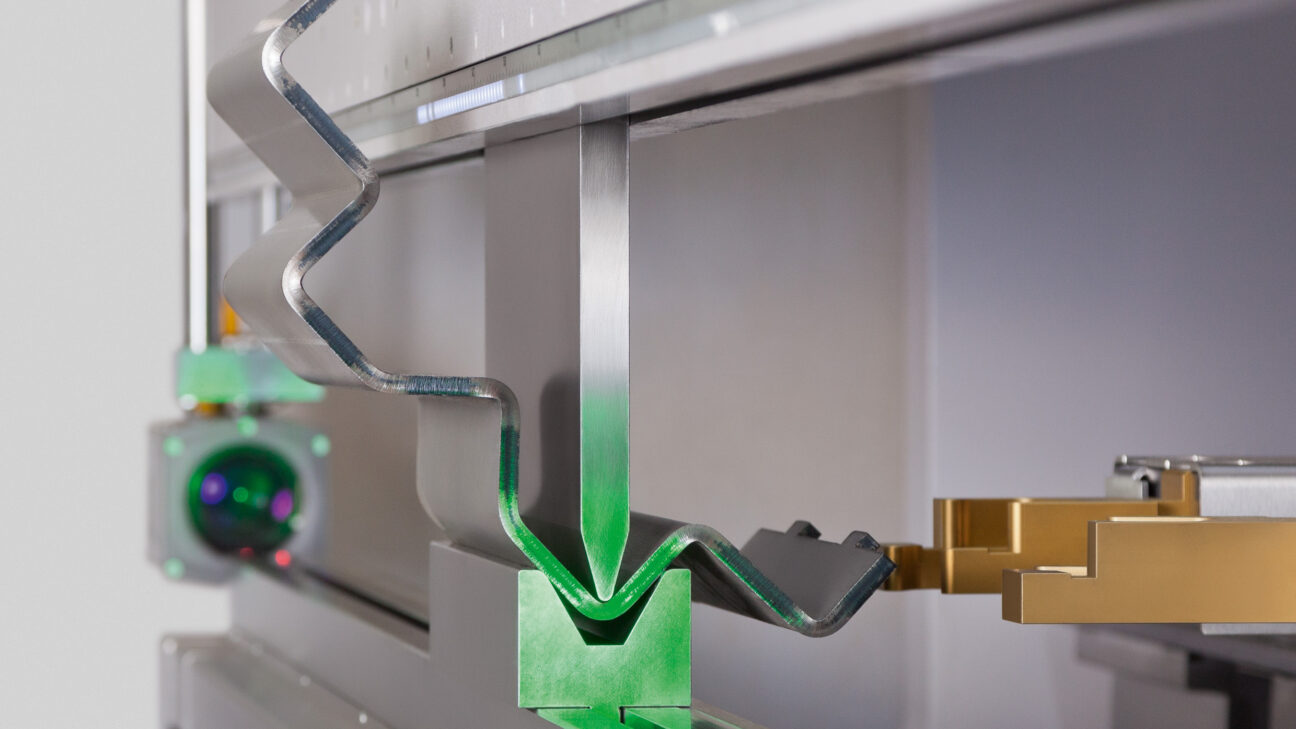

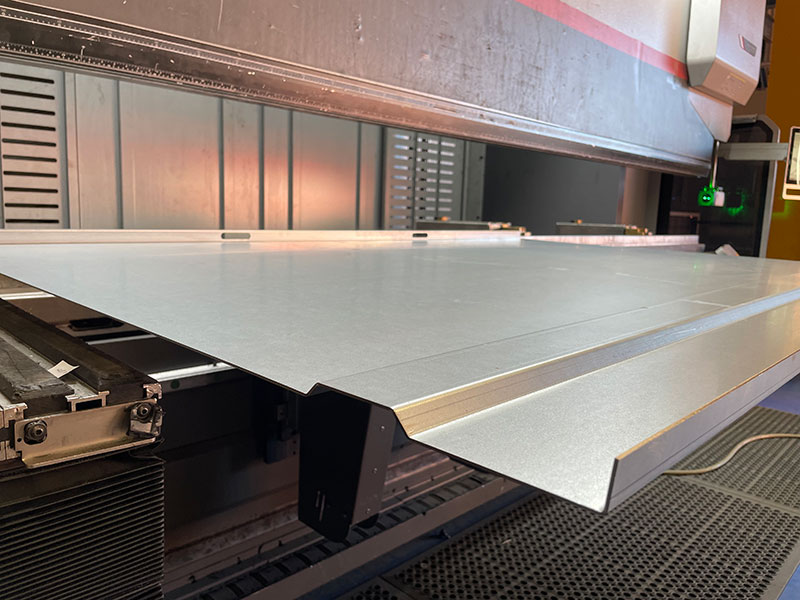

In-House Bending and Pressing

Charles Day Steels enhances our flatbed cutting solutions with comprehensive in-house metal bending and pressing services. Our facility supports swift project completion and continuous 24-hour production, streamlining your project’s assembly phase while ensuring top-tier quality.

Our capabilities extend to bending and pressing an extensive variety of materials, including mild steel, stainless steel, aluminium, copper, and others. For further details about our metal bending and pressing offerings, please reach out to our team.

Aluminium Cutting Grades and Capabilities

Aluminium Laser Cutting Capabilities

Maximum Cutting Size

6m x 2.5m (6000mm x 2500mm) – For larger sheet sizes we recommend waterjet or plasma cutting.

Maximum Material Thickness

40mm

Minimum Material Thickness

0.4mm (Technically we can cut thinner than this but given the malleability of aluminium at such low thickness it can be tricky.)

Complex Details

Our CNC-driven laser-cutting machines are able to process even the most complex and intricate designs.

Cutting Tolerances

View our laser cutting tolerances here.

Cutting Edge Quality

Laser cutting aluminium and aluminium alloys provide a smooth finish quality, although this is sometimes degraded slightly on thicker sheets. As we shroud the laser in Nitrogen gases, it prevents oxidisation ensuring we achieve a clean, blemish-free cut, ready for welding without any extra machining.

We’re able to laser cut aluminium plates and sheets in all grades as well as numerous aluminium alloys. Some of the more common grades we get asked to cut include:

- 1050A

- 1200

- 2014

- 5083

- 5251

- 6061

- 6082

Even if the grade you require is not listed, we could still source and cut it for you. Please contact us with your preferred grade and requirements.