How to Clean and Maintain Tarnished Stainless Steel

Key Points: Stainless steel is an incredibly popular, versatile and tensile metal, particularly renowned for its corrosion resistance. Utilised across both industrial and domestic applications,

Key Points: Stainless steel is an incredibly popular, versatile and tensile metal, particularly renowned for its corrosion resistance. Utilised across both industrial and domestic applications,

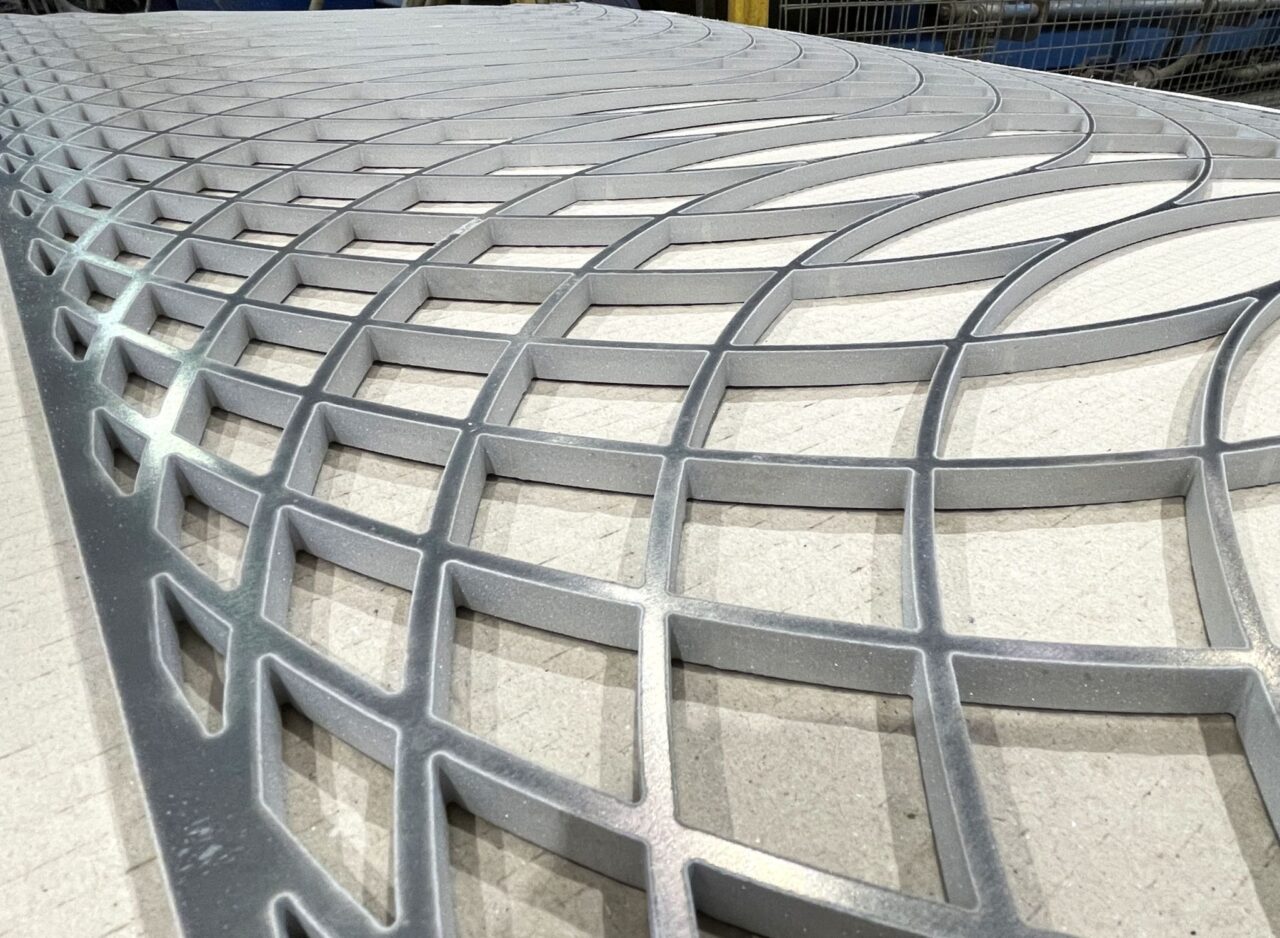

Key Summary Within the manufacturing industry, maximising material efficiency is a prime focus, particularly when it comes to profile cutting. Whether working with metals, plastic,

To prepare engineering and manufacturing with the best start, it’s integral to choose an effective material that is not only high in quality, but can

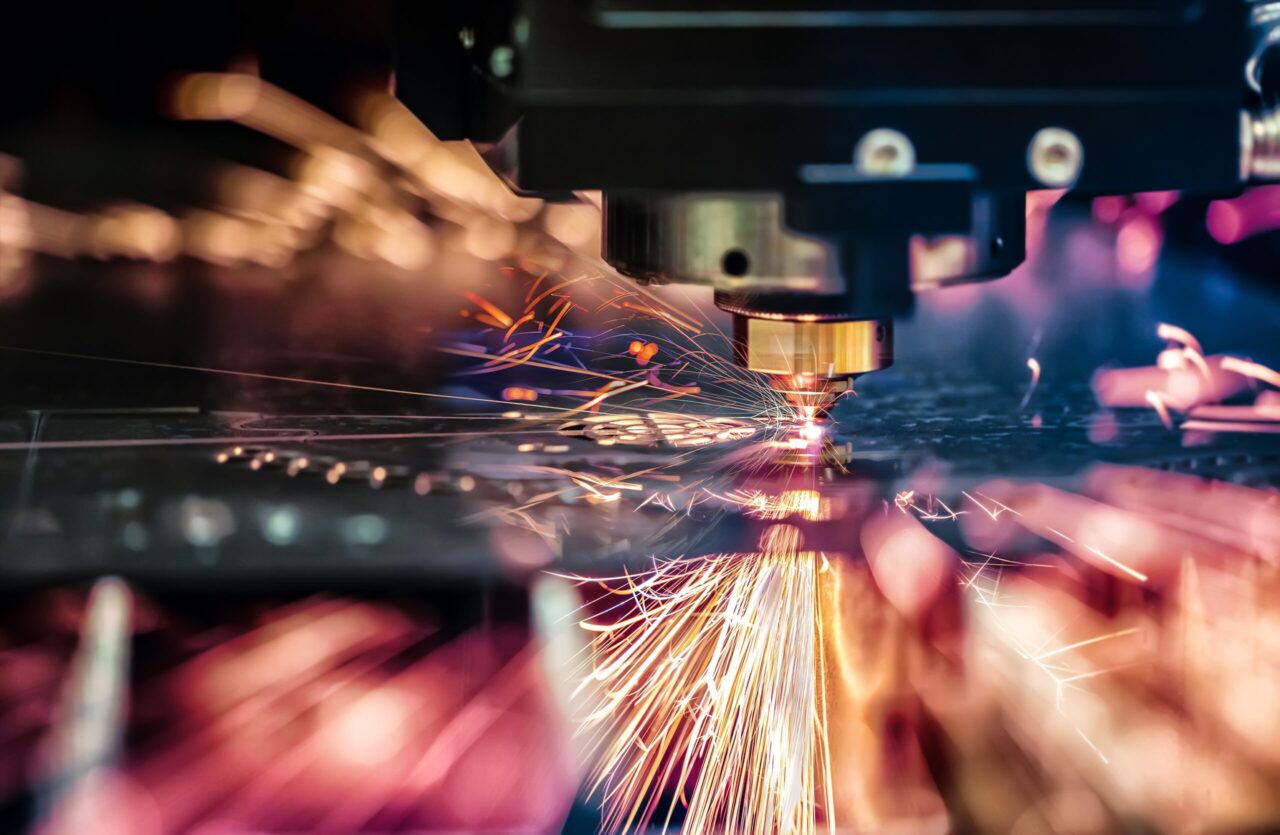

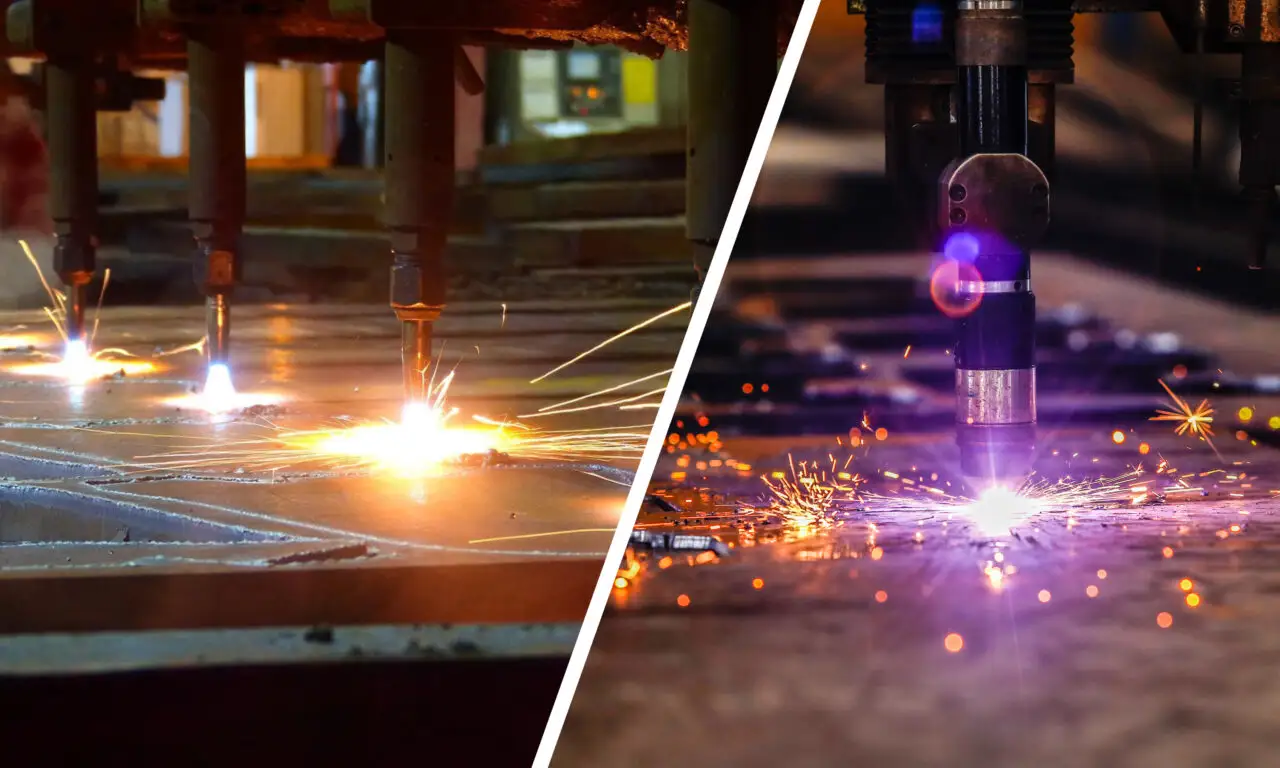

Metal cutting plays a vital role across various manufacturing sectors to facilitate the unique requirements of several industries. With its diverse capabilities, the steel industry

Stainless steel is regarded as a highly durable and low-maintenance material, making it a popular and widely used metal across the globe due to its

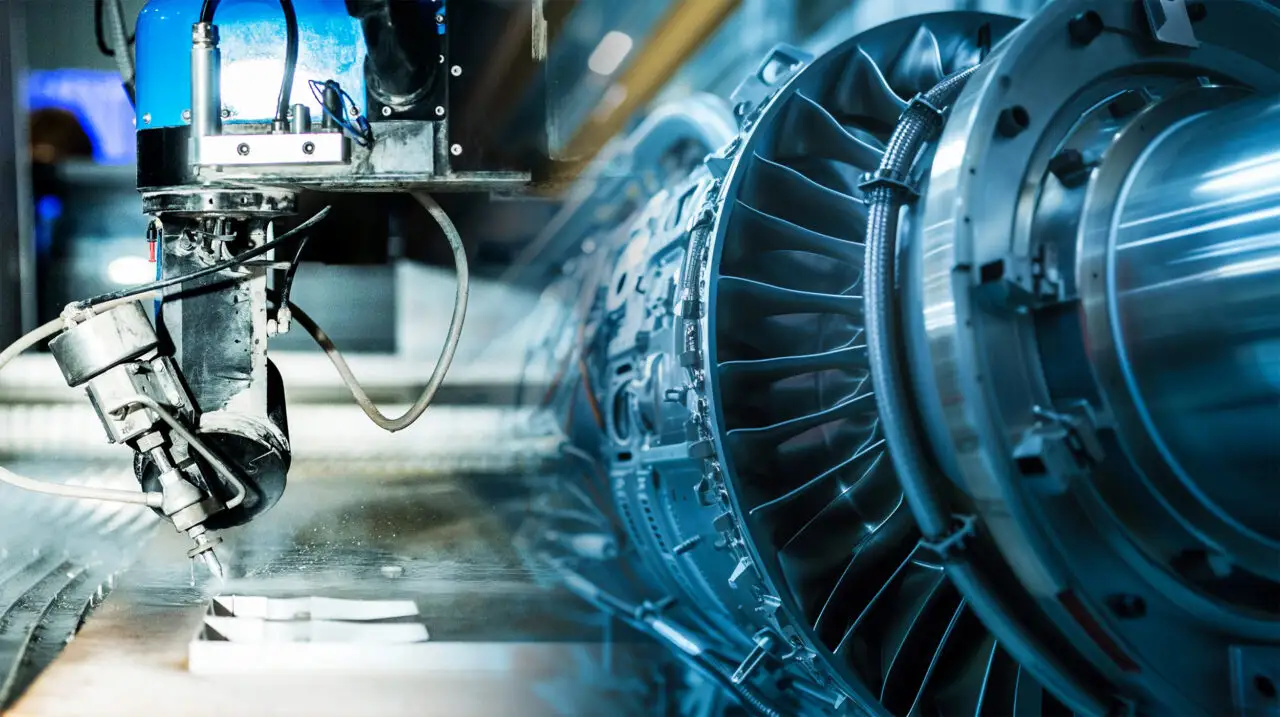

The use of aluminium has become indispensable across several sectors, most notably within automotive and aerospace industries where there is an essential requirement for lightweight

A pioneer in metal profiling, Charles Day Steels, proudly announces the launch of their progressive 50-degree Laser Bevel Cutting machine. This innovative addition to their

Since 1976, Charles Day Steels has campaigned for green initiatives in the laser cutting industry. We have strived to make environmentally conscious decisions as part

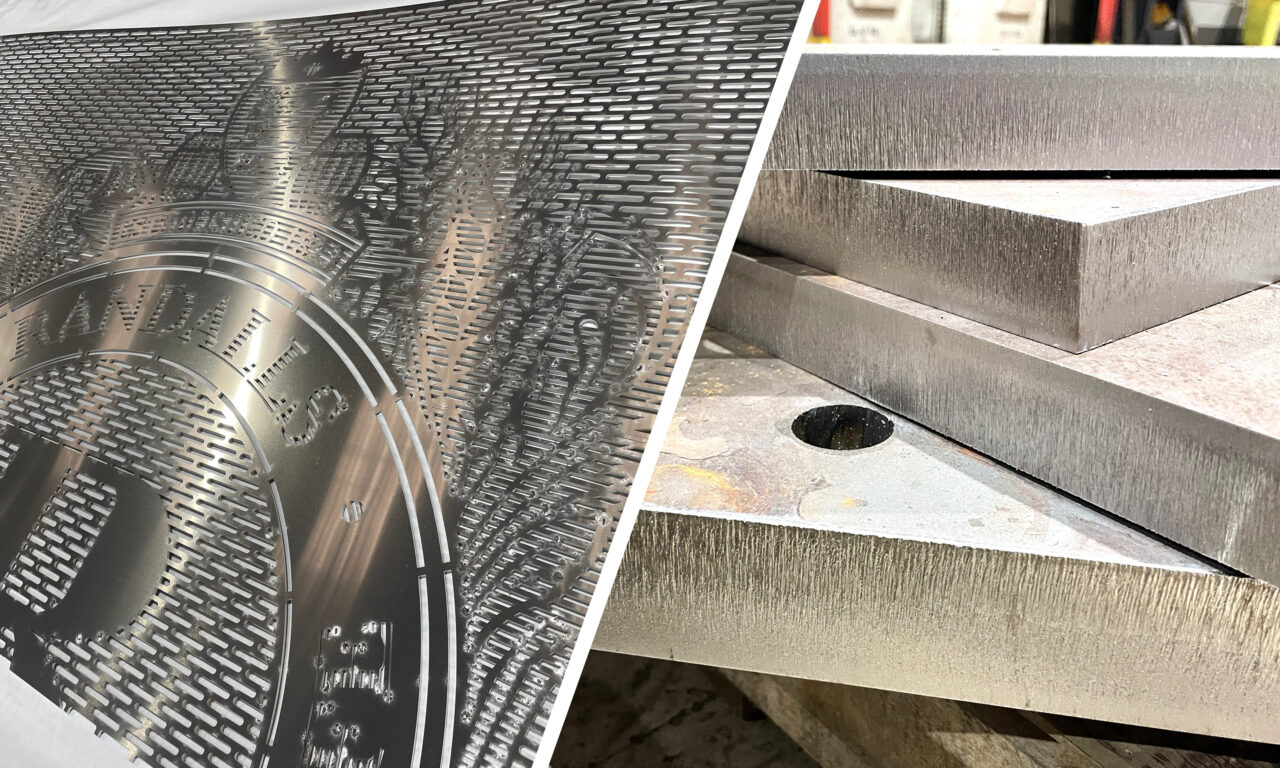

At Charles Day Steels, we understand the difference between laser etching and laser engraving can be confusing. With over 45 years of expertise, we know

At Charles Day Steels, we understand that quality and compliance are non-negotiable when it comes to industrial manufacturing. Our commitment to delivering exceptional metal profiling

Bevel Cutting Applications in Aerospace Engineering The aerospace industry, known for its high standards and precision requirements, often turns to advanced cutting techniques to meet

Here at Charles Day Steels, our many years of experience and expertise mean that we understand more than most the importance of selecting the correct

From 1976 Charles Day (Steels) has evolved into one of the largest and diverse specialist profile cutting companies in the UK.

Charles Day Steels,

6 Downgate Drive,

Sheffield, S4 8BT

Phone: 0114 244 5544

Email: sales@daysteel.co.uk

Copyright © Charles Day Steels. Website built by Fenti Marketing