Committed to consistent reinvigoration, we invest in only the very best technology, machinery and materials available in the industry – all for the benefit, simplicity and convenience of our customers. Providing expert profile cutting solutions in the heart of Sheffield for over 4 decades, our company ethos has always centred around providing a fully comprehensive and seamless service; from material procurement, to metal processing, shot blasting and metal finishing. Our diverse cutting facilities and downstream efficiency means we are able to offer competitive lead capacities, with rapid turnaround.

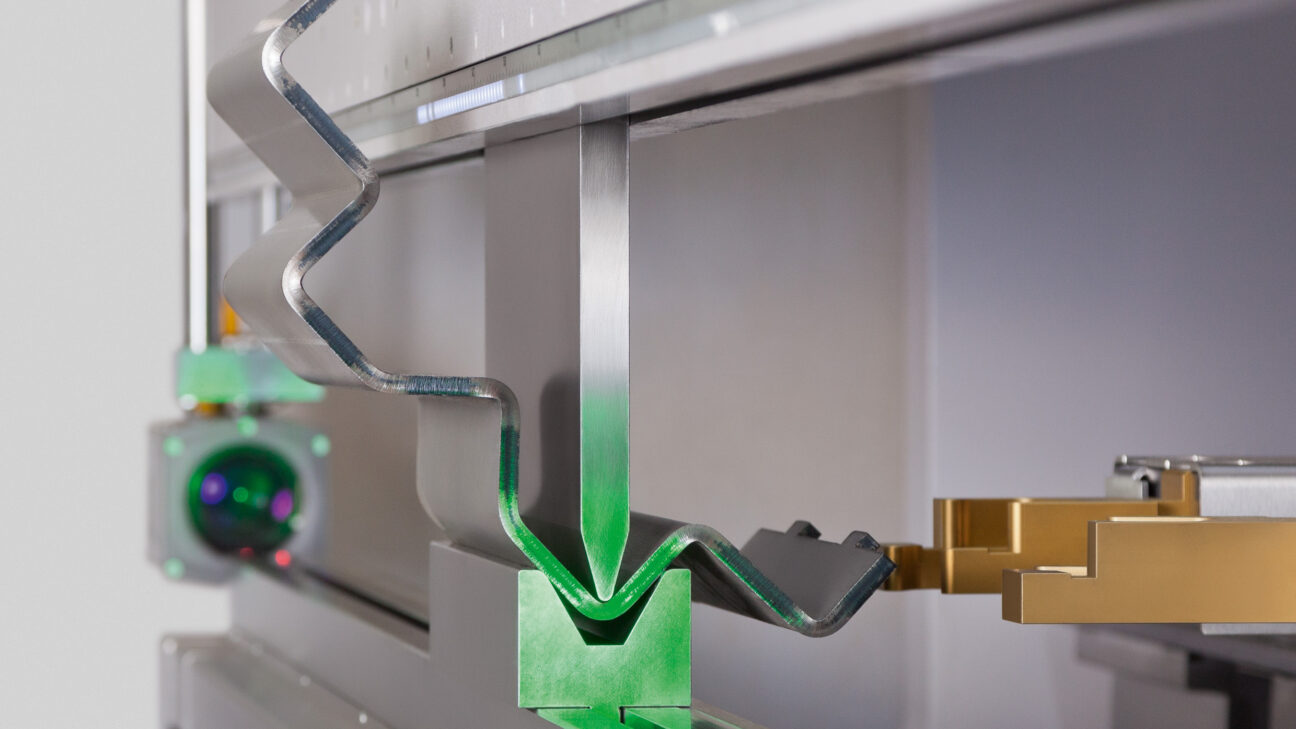

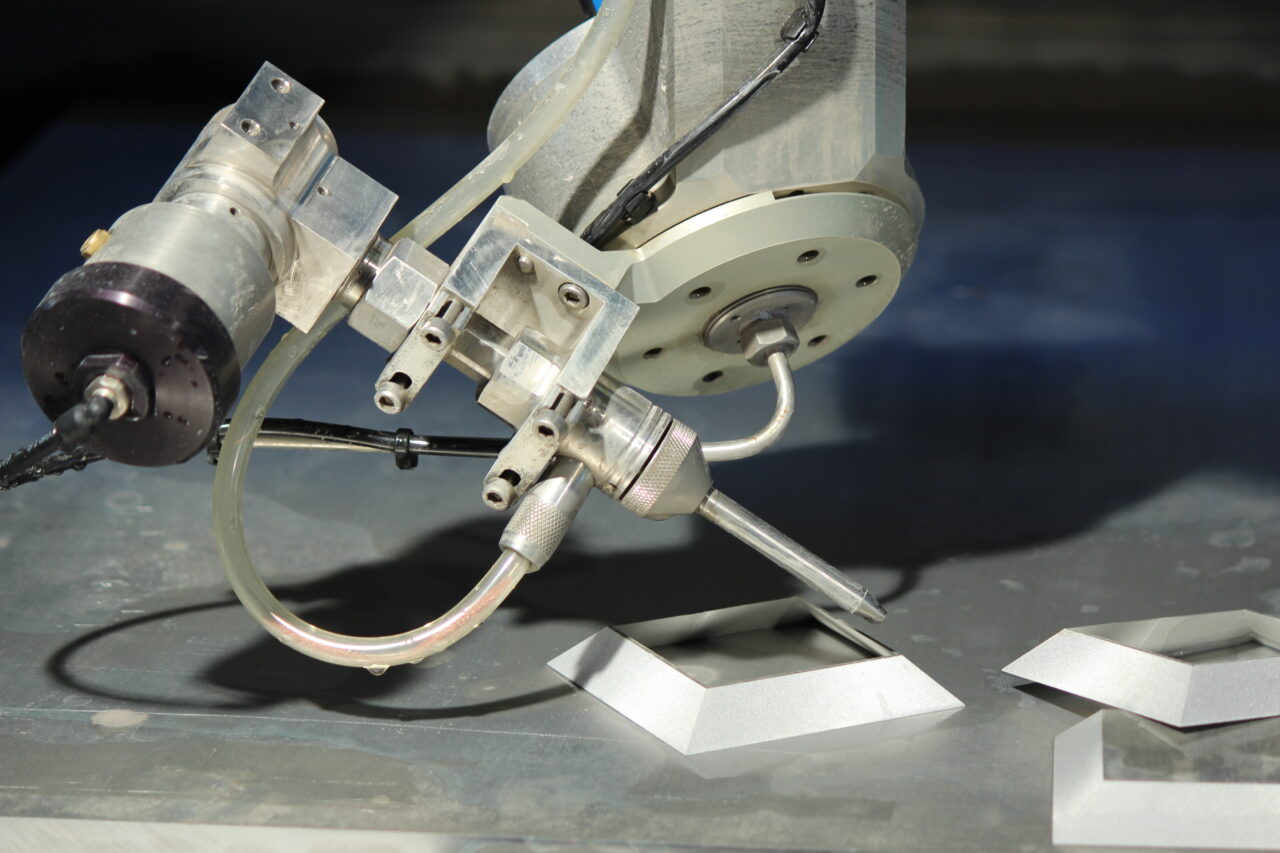

Our latest investment is a state-of-the-art Waterjet Sweden Beveljet 60 waterjet cutting machine, alongside a 125hp pump. Equipped with an unrivalled suite of industry-defining profile cutting machines, including laser, water, flame, and plasma cutting, our latest addition allows us to extend our already expansive services to include 3D bevel cutting. Now with our latest addition, our facilities are simply unrivalled; hosting some of the most expansive and diverse range of profiling machinery available in the UK, all under one roof.

Benefits Of Using a Waterjet Sweden Bevel 60 Machine

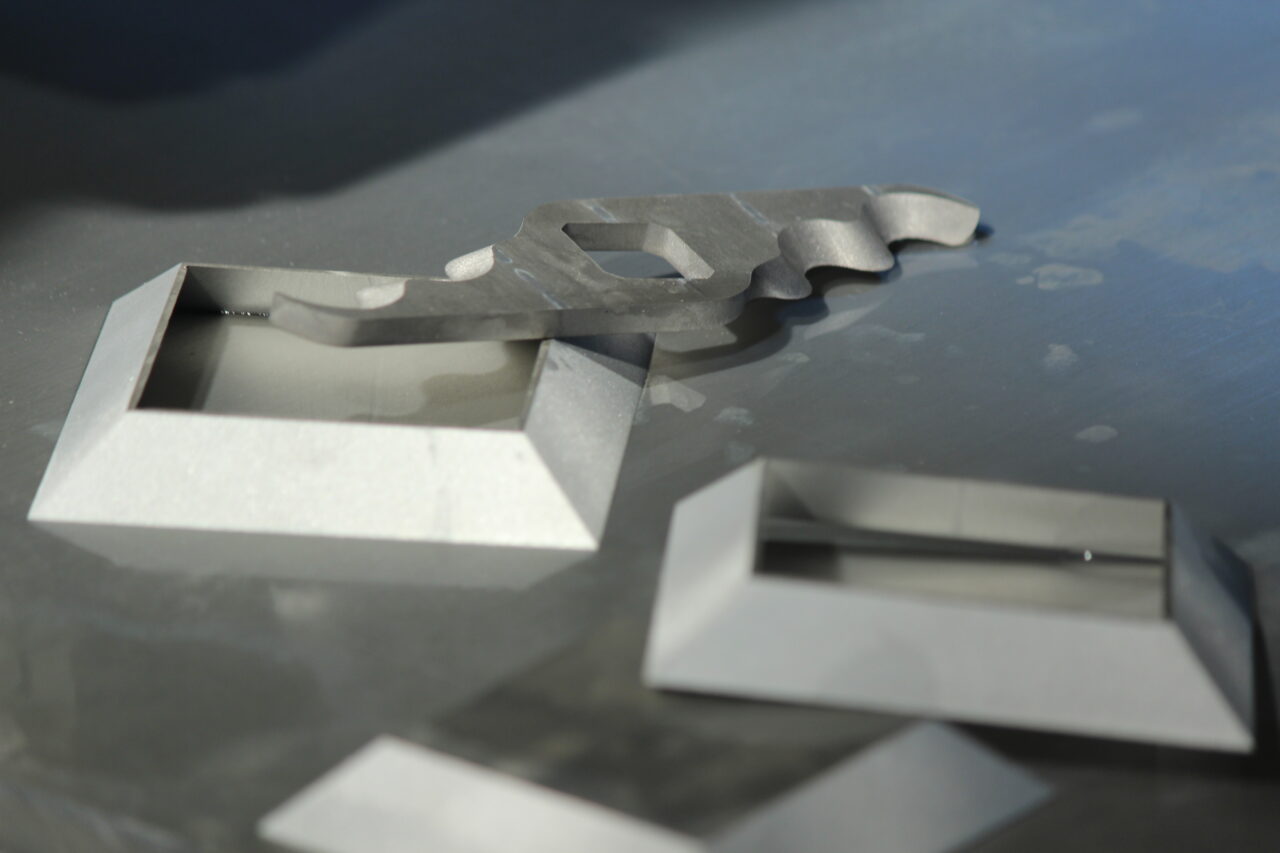

The Waterjet Sweden Beveljet 60 machine developed by industry leaders, Water Jet Sweden, offers some of the most advanced waterjet cutting capabilities available on the market. Extremely versatile, this waterjet cutting machine rapidly increases the speed at which waterjet parts can be processed.

With typical waterjet pumps only offering between 50-60hp on average, the pump Charles Days has invested in is able to produce up to 125hp; creating exceptional cutting speeds, and even more competitive pricing for customers. This increase in efficiency and capability, coupled with our BSEN 1090 EXC4 accreditation, also allows us to comfortably service both the nuclear industry, and the aerospace industry in accordance with ISO9100.

Benefits

- Beveljet 60 head allows for 3D parts to be processed up to 60 °

- 125hp pump allows for 6200 bar cutting

- Dual heads (3D and 2D) allows for simultaneous cutting of up to 6200 bars of pressure through each head

- Reduced production times

- Adjustable pressure for rapid cutting speed

- Cutting bed measuring 4m x 8.5m

Waterjet Sweden Beveljet 60 Applications

- Metal profiling for aerospace & defence industries

- Metal profiling for oil & gas industries

- Metal profiling for nuclear industries

- Specialist metal profiling, fabrication & sheet metal cutting

Additional Features

- Harmonic drive gearbox

- Maintenance free lifetime lubrication

- Fanuc nano interpolation

- 3D free form cutting

Why Choose Charles Day For Bespoke Profile Cutting?

Boasting an unrivalled collection of the latest and most advanced profiling machinery at our purpose-built facility, including our latest waterjet cutting machine, we here at Charles Day always go above and beyond to ensure our customer’s every requirement is met. As an ISO 9001:2015 accredited manufacturer and supplier, exceptional quality is always at the forefront of our practices; with 24-hour production, large-scale cutting capabilities, and nationwide delivery, an accurate, efficient and professional product is always guaranteed.

Get In Touch For a Bespoke Waterjet Cutting Quote

As leading providers of waterjet cutting, we are always happy to provide our customers with any guidance and advice they may require. If you’re interested in acquiring a bespoke waterjet cutting quote, get in touch with the team at Charles Day today.