We’re proud to announce that we have invested in two brand new, high powered CNC laser cutting machines from Bystronic UK, a clear sign of our ongoing commitment to remain at the forefront of the laser profiling industry.

After the extraordinary success of our previous two Bystronic 3kW Bysprint Fibre 3015 and 6kW Byspeed Pro 3015 lasers installed back in 2013, we chose Bystronic lasers again as we further expand our laser cutting capacity. Our investment includes the latest cutting-edge technology with the 6kW Bysprint Fibre 4020 and 6kW Bysprint Pro 4020.

The decision to invest in a second fibre laser has already helped us tap into sectors we previously would have struggled to be competitive as well as helping us improve our offering to our existing customers.

What does this mean for our customers?

- Faster lead times on laser cut profiles

- Cost savings passed onto customers due to lower running costs

- Lower environmental impact

- Reflective metals such as brass and copper can be cut up to 10mm on laser

- We now have 6 laser machines running 24/7

- A larger 6m x 2.5m cutting bed on our fibre laser

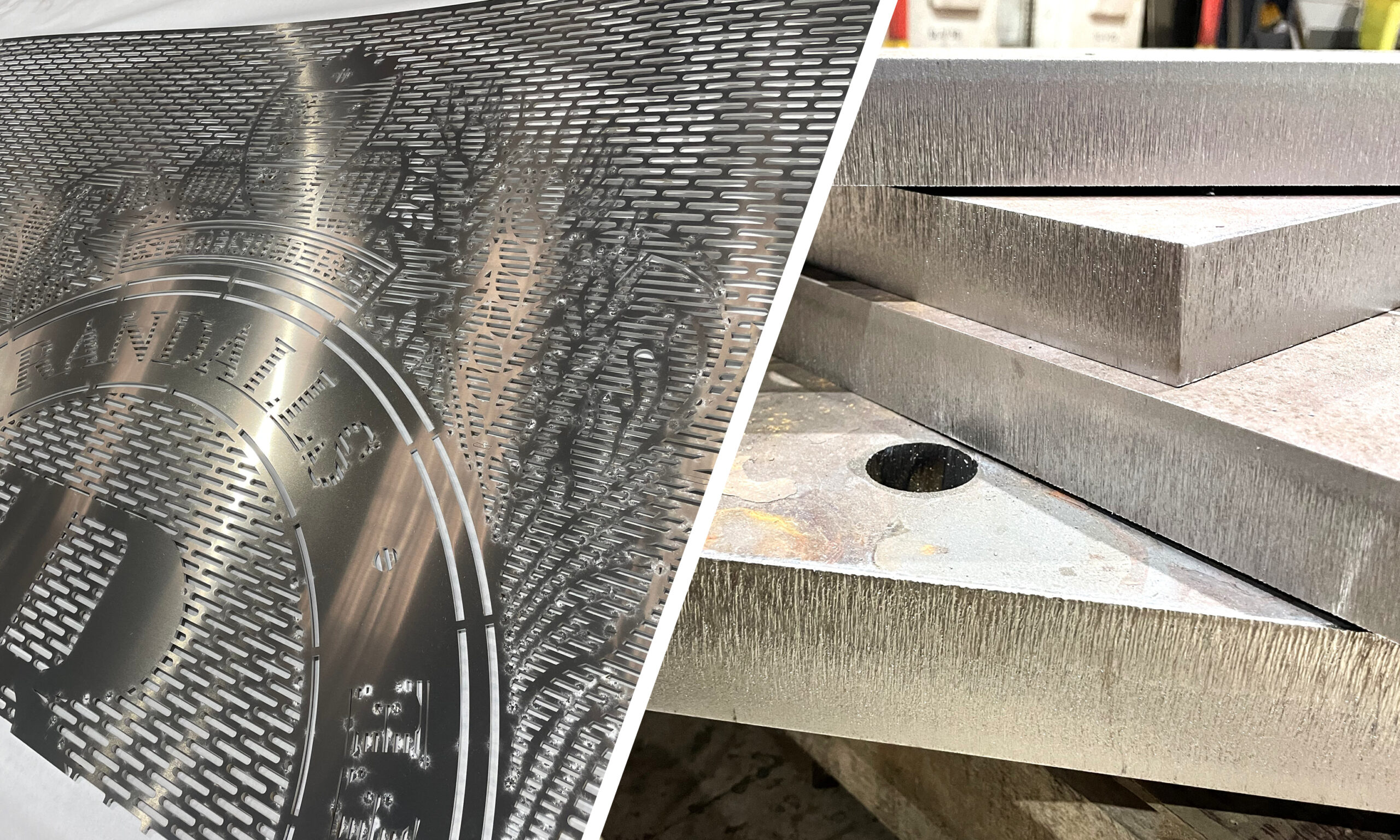

With the new 6kW Bysprint Fibre 4020 we have secured a machine which excels at cutting thin, reflective metals such as aluminium, copper and brass up to 10mm. These reflective metals have often proved problematic to cut on traditional CO2 lasers but fibre technology is inherently better suited for these materials. So much so we’re even starting to become competitive against punching!

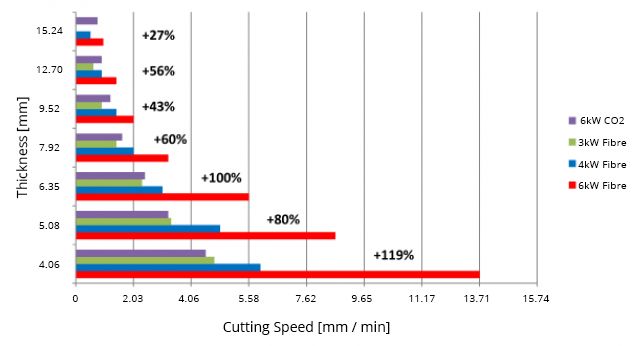

When we originally installed and started cutting with the 3kW fibre laser we were really impressed with the ease and speed and which it cut through thin and reflective metals. However as you can see in the below graph, the 6kW fibre laser far exceeds the performance of the lasers on all thicknesses of aluminium, even being able to cut 15mm Aluminium.

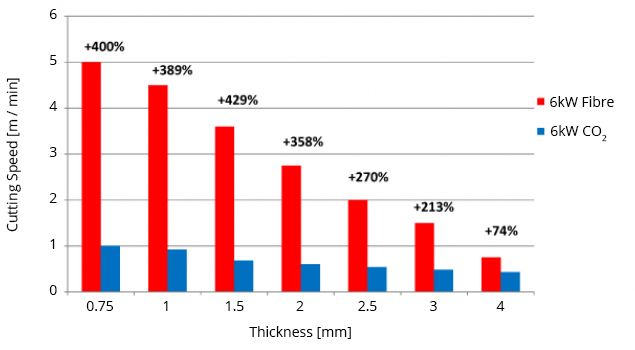

Fibre laser technology is an advanced alternative to the conventional CO2 laser cutting process offering higher reliability, less power consumption and on 3mm stainless steel a 6kW fibre laser is up to three times as fast as a 6kW CO2 laser.

Depending on the type of material and sheet thickness, parts output can be increased by up to 400 percent, with the subsequent cost-saving benefits passed onto their customers while maintaining the excellent quality, precision parts that they have come to expect.

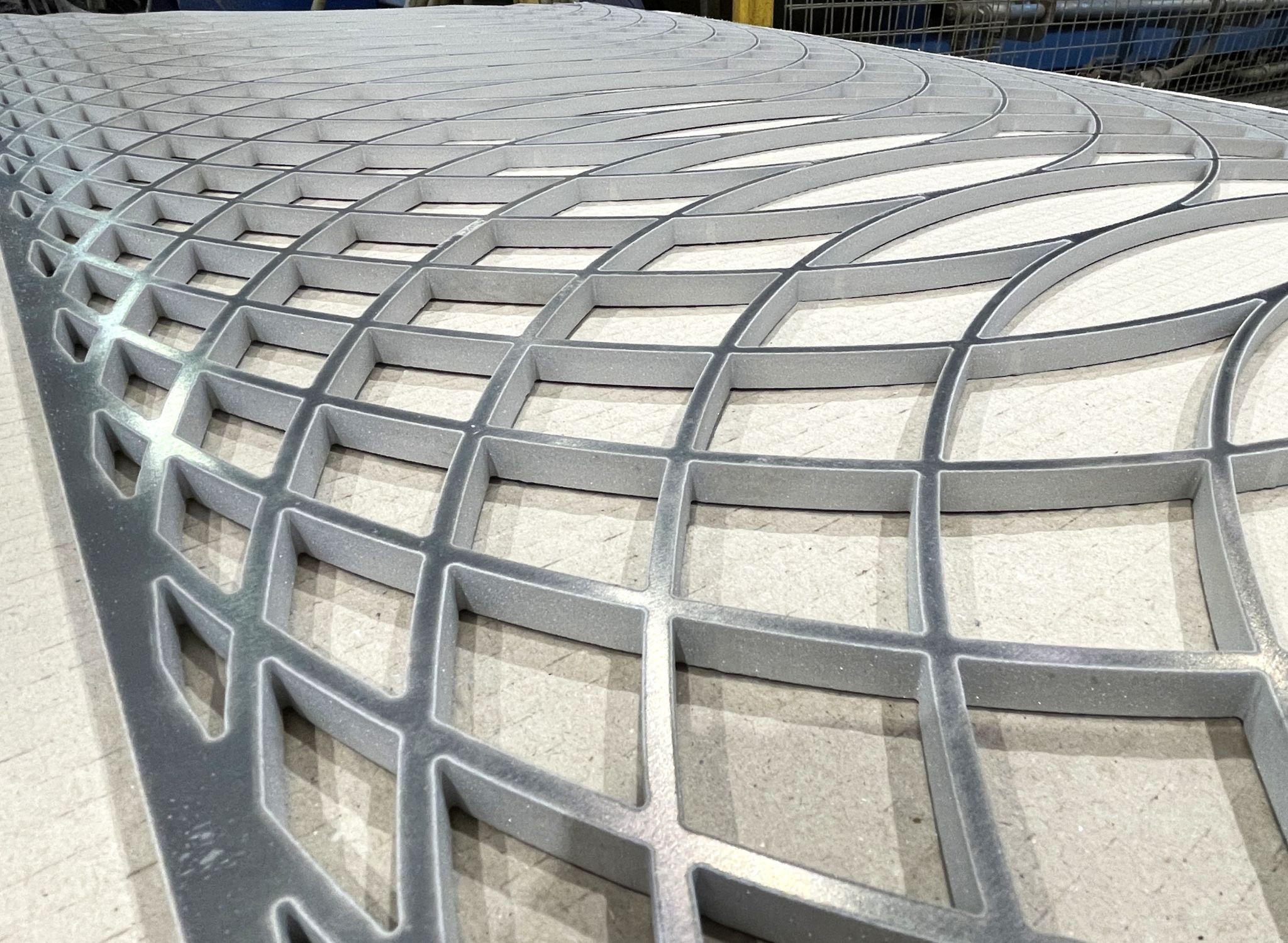

In addition to maintaining our reputation of being on the cutting-edge of laser profiling technology, the CNC systems behind the two new lasers are at the forefront of computer-driven cutting technology, guaranteeing a high precision profile regardless of the complexity of the requirement.

The increase in capacity is set to offer productivity across a full range of sheet thickness up to 25mm, perfectly complementing our traditional flame cutting, waterjet cutting and high-definition plasma profile cutting services.

As a result, we have further established ourselves as a major player in the profiling industry by offering world-class sub-contract profiling services under a single roof.

*Graphs courtesy of Bystronic (Measurements converted from inches to mm).