Reduced waste and improved product quality, without inflating cost, is essential in the new age of manufacturing. The most effective way to achieve such high precision is through advanced technologies, like laser cutting. Precision laser cutting is a popular investment strategy, proven to offer excellent accuracy, reduced material waste, rapid lead times, and significant savings in both money and time.

How Precision Cutting Saves Time and Money

Weld Preparation Cutting and Laser Bevel

Traditionally, weld preps on 2D parts required manual grinding to create the correct edge angles, increasing labour and material wastage. With bevel cutting, components can be produced ready for welding straight from the machine, eliminating the need for secondary grinding. This streamlines production while also improving occupational health and safety concerns, ensuring workers are not routinely exposed to vibration-related injuries, such as vibration white finger, and inhalation of fine steel dust. Laser weld prep cutting removes these risks due to a non-contact, automated process that results in faster, more efficient workflow.

Reduced Material Waste

An immediate benefit of precision cutting is the reduced material waste that is normally attributed to the manufacturing process. Traditional cutting methods, such as punching or sawing, will often lead to an increase in offcuts and inconsistencies, resulting in the need for secondary finishes or discarded parts. Over time, this can lead to accumulated costs, which are detrimental when working with expensive materials. Laser cutting delivers remarkable accuracy within fine tolerances, allowing for optimised material nesting techniques and consistent execution. The result highlights less waste, lower overall cost, rapid speeds, and a more sustainable cutting process.

Rapid Lead Production

Utilising time effectively is incredibly valuable across profiling. As components can be cut more quickly and to a high level of quality, businesses can procure products at higher volumes. Precision laser cutting is excellent at reducing production times, offering a seamless transition between materials and producing complex, intricate designs within minutes. Additionally, laser cutting systems can operate on a continuous basis, providing around-the-clock operations with minimal supervision. The development of automation systems allows manufacturers to meet tight deadlines, respond promptly to consumer demand, and minimise downtime.

Minimised Post Processing

In many scenarios, a component may require additional finishing services to achieve a client’s expected standard. This can involve processing burrs, rough edges, or inaccuracies, which all add to the time and cost required. Laser cutting significantly reduces this element, providing clean, burr-free edges in most cases, saving cost on labour and time. Streamlining the entire production journey allows components to reach clients and consumers faster and obtain higher-quality outcomes.

Greater Accuracy and Consistency

Achieving consistency and reliable results is incredibly important, whether it’s a singular part or large-scale production; each piece must meet its exact specifications. Reduced consistency in parts can severely impact the production schedule, which is why sophisticated software through CAD machines can produce and execute digital designs with ease. This eliminates the risk of human error and ensures clients can expect each part to be produced equally.

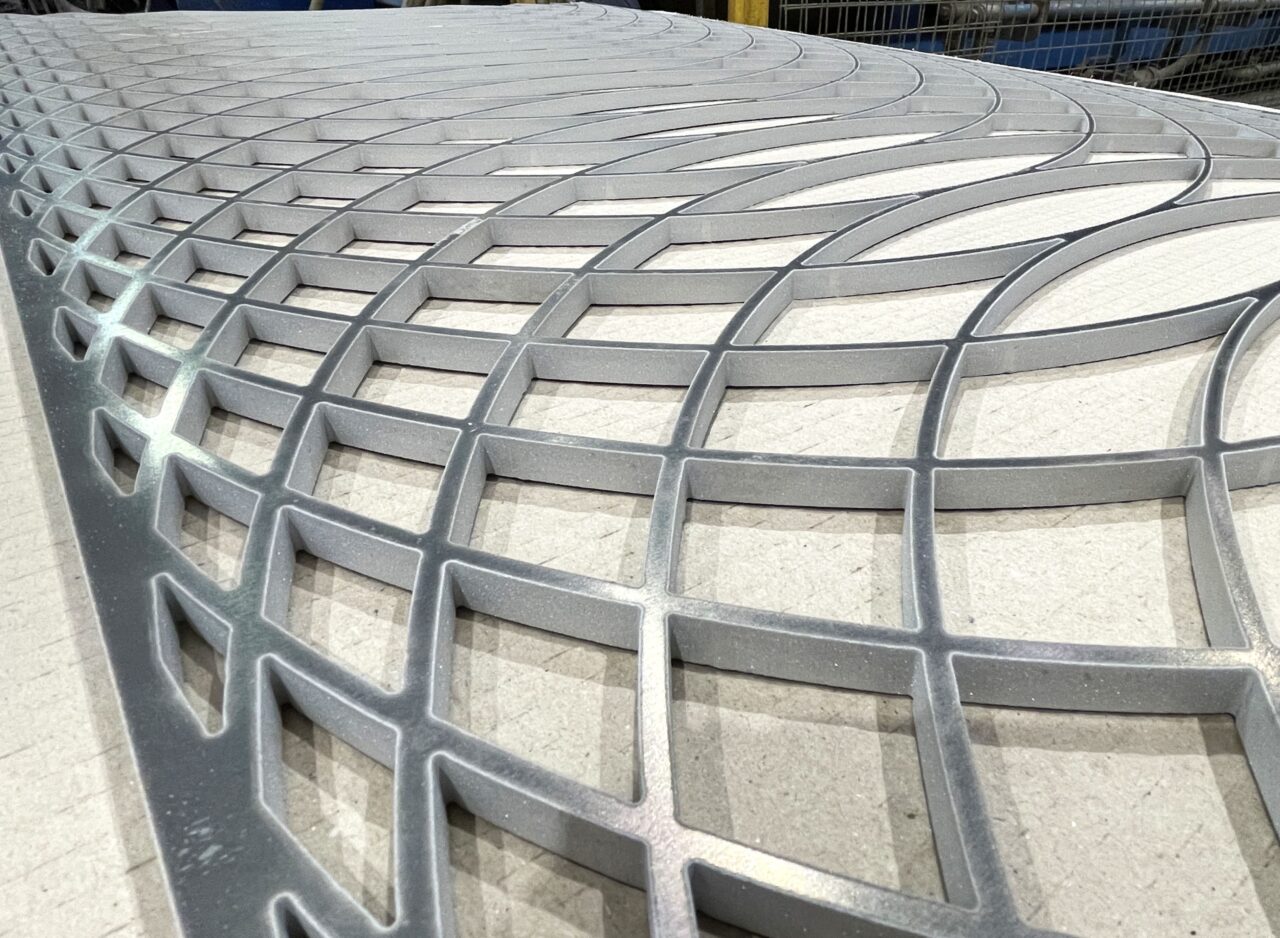

Flexible Design

Laser cutting opens the scope for greater design capability, without compromising on quality. Laser technology can produce intricate and complex geometries that would otherwise be incredibly difficult to process when using traditional methods. This gives creative freedom for clients and manufacturers, providing more room for prototyping and modifications without losing time or money. Through agile, non-contact methods, businesses can promptly respond to market fluctuations and customer requirements.

Lower Maintenance Costs

With traditional methods, tools wear down and require replacement and costly maintenance, effectively increasing downtime and impacting quality. Laser cutting uses a non-contact approach to profiling, ensuring that no blades or external components are required, eliminating the need for replacement parts. The requirement for regular, thorough maintenance is typically much lower, with laser technology typically not suffering greatly from mechanical stress, unlike conventional tools. This results in more reliable, predictable production processes and minimal interference.

Improved Safety and Hygiene

Laser cutting technology is designed to be entirely safe for operators due to its automated software and materials benefiting from a non-contact process, which improves structural integrity and hygiene, an important aspect when used in sterile environments. Laser cutting also creates cleaner environments for staff, with less dust, debris, and contaminants in work zones. This added benefit contributes to reduced expenses and loss of production by minimising the time spent off work and the need for frequent equipment cleaning or repair.

Discover High-Precision and Quality Laser Cutting

The team at Charles Day Steels proudly operate an advanced fleet of lasers that can effortlessly process materials, regardless of scale or complexity. Under one roof, we encompass a range of material cutting services, from rapid laser cutting, bevels and countersinks to engraving and pressing solutions.

We work closely with our clients to achieve quality outcomes, offering dynamic approaches across all bespoke requirements. Whether you’re developing prototypes, scaling production, or require intricate design, Charles Day Steels offers expertise and guidance at each step. Contact our team today to discover how our laser cutting solutions can transform your profiling needs.