Flame cutting is a process that is used to cut through thick metal, predominantly mild steel. It is a process used in all types of industries, from manufacturing to aerospace. But despite its widespread use, it is often confused with other cutting processes, like laser and plasma.

As experts who have been laser cutting for over 45 years, we have created a guide to flame cutting. In it, we will discuss what flame cutting is and how it is used, as well as its advantages and disadvantages to help you to understand what flame cutting is and how it differs from other types.

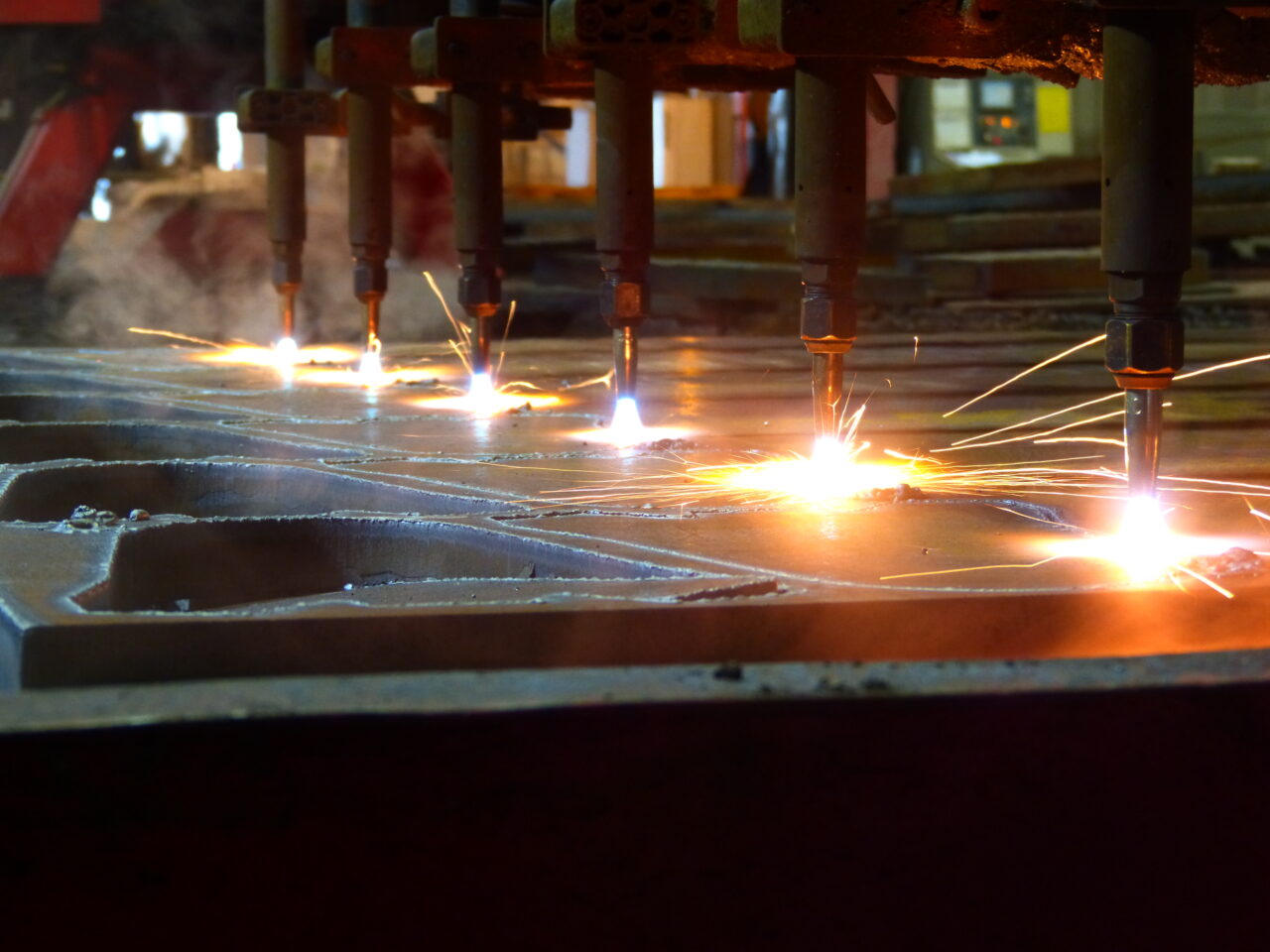

Flame cutting is a process that involves cutting steel and other metals using oxygen and a gas as fuel. This gas can be acetylene, propane, or natural gas, which is why the process can be known as oxy-fuel cutting or oxy acetylene cutting.

It is a type of thermal cutting method that, as its name suggests, using heat to cut through hard material.

How Does Oxy Fuel Cutting Work?

Fuel cutting heats up the metal along the desired cut line using a flame fuelled by gas. The metal is heated up to a point where it is almost melted. Oxygen is then used to blow the almost molten metal away which causes the metal to be spilt into two.

The Advantages Of Flame Cutting

This is how fuel cutting can be used so effectively on thick metals, including everything from steel to aluminium. What’s more, because the process only uses a gas for fuel and an oxygen source, it is a relatively cost-effective and and easy process.

The Disadvantages Of Flame Cutting

However, although it can be used to cut hard metals, like steel, there is a limit to the maximum thickness that can be cut. Typically, 270mm of metal is the limit for a single pass using a flame cutter. And this leaves a melted edge along the cut line and slag, which require additional work after the cutting has finished.

Additionally, the process of flame cutting generates a lot of heat, which can cause warping or distortion of the material being cut. This is one of the reasons why this process should only be used for thicker material or larger profiles.

So as effective as flame cutting can be, there are some limitations to the process. Other types of thermal cutting may be more suitable for your project.

What Is The Difference Between Plasma And Oxy Fuel Cutting

Flame cutting is a type of thermal cutting. But there are other types too, including plasma cutting and laser cutting. Although the different types are often confused, it is important to understand what each is and which is the right process for your project.

Plasma Cutting

Plasma cutting is faster, more precise and provides a better edge finish than flame cutting. It uses an electric arc to heat up the metal, rather than a gas fuelled flame. Compressed air, not oxygen is then used to blow the molten metal away. However, because plasma cutting uses electric arc not gas, it is not effective for metal with more than 1 inch thickness.

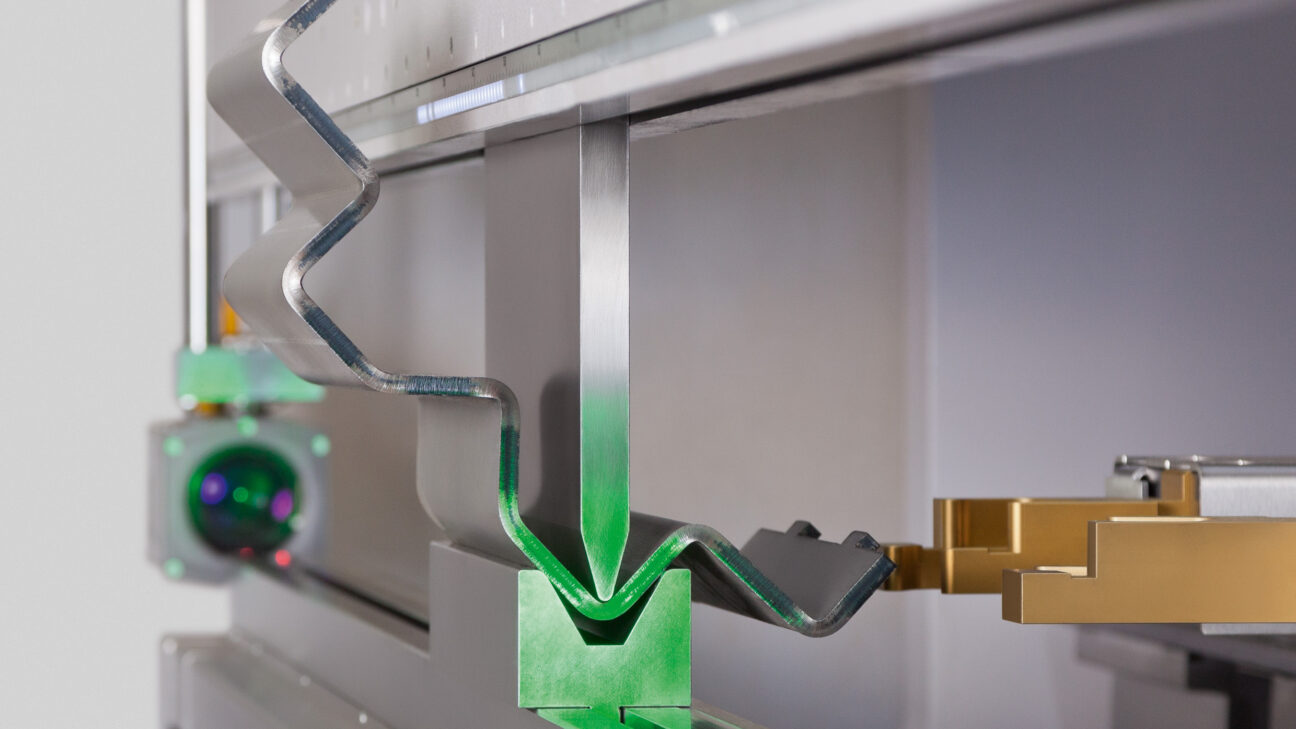

Laser Cutting

Laser cutting is the most accurate of the three thermal cuts, providing a perfect edge. It uses a laser, as the name suggests, which vaporises the metal splitting it along the cut line. However, because laser cutting is controlled by a computer, the equipment needed is far more expensive. So although the finish is better, it tends to cost more.

How To Get Your Steel Flame Cut

Depending on your project, flame cutting is a cost-effective and versatile method of cutting thick metals like steel. It is most useful for one-off cutting jobs where additional finishing time can be built in to make the cuts more precise. However, without training and the necessary skills to operate the equipment, flame cutting can be dangerous. It is important to remember that flame cutting requires the use of combustible gases and storage of bulky equipment, which can mean that outsourcing your flame cutting needs may be the more efficient option.

At Charles Day Steels, we have over 45 years experience in flame cutting. Our accurate in-house programming ensures cost-effective processing and material is finished and treated to customer own individual specifications. Contact our team today for your flame cutting needs.