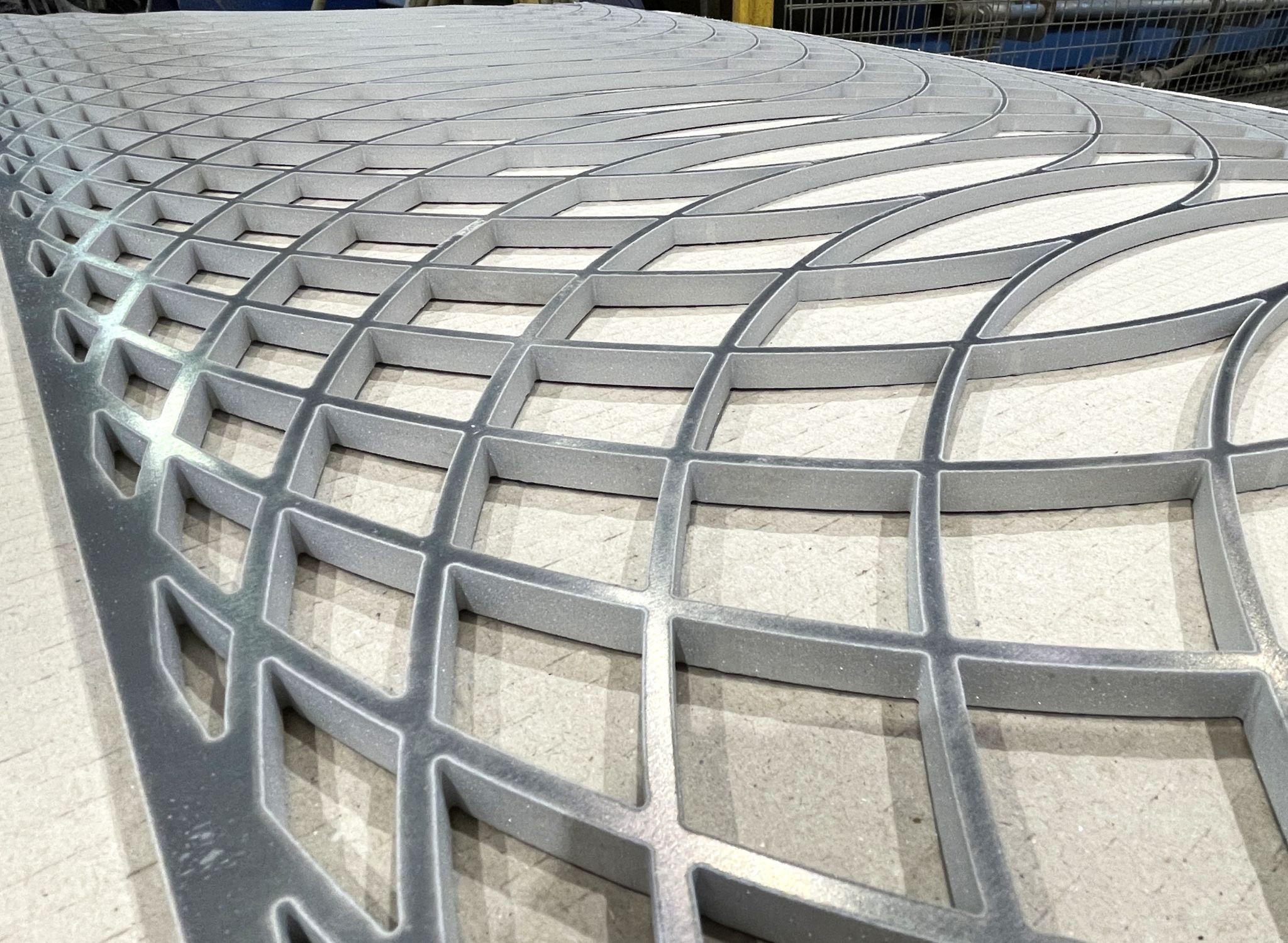

One of the major benefits of waterjet cutting technology is its ability to profile a wide range of materials, it is not limited to operating on a ‘metal-only’ basis like our laser and flame cutting technologies.

This ability really comes into it’s own when considering plastics, with there being so many different types, such as nylon, polyethylene, acrylic and even carbon fibre reinforced plastics, being able to cut them all using a single process is a great advantage.

Cutting plastics by water jet is possible due to the absence of heat in the process, meaning no toxic fumes are released and there is no chance of melting the plastic itself. Ensuring a consistant, uniform cut edge is provided around the part.

Waterjet Cutting Plastic Capacity

With almost a decade of waterjet cutting experience and investment behind us, we’re able to offer one of the largest waterjet cutting capacities in the UK.

Water jet machines – 3

Cutting bed size – 8m x 4m

Max. plastic thickness – 230mm

Edge quality – Variable, more information can be found on our waterjet page.

Carbon Fibre Reinforced Plastic

Used throughout specialist industries such as aerospace and automotive/sports, these advanced plastic composites are easily processed by our abrasive waterjet cutting machines. Waterjet cutting carbon fibre plastics has many advantages as other methods, including no melting, no heat affected zone (HAZ), no tool wear and no hazardous fumes.