Key Summary

- Smart nesting and CAD software help minimise waste and maximise yield from each material sheet for optimal layouts and precision.

- Choosing the right cutting method based on the material type will enhance accuracy and increase success rates.

- Recycling offcuts and adopting sustainable practices help manufacturers cut costs and meet environmental standards.

- Regular equipment maintenance and training help to improve cut quality, reduce post-processing, and ensure consistent results.

Quick Links

Within the manufacturing industry, maximising material efficiency is a prime focus, particularly when it comes to profile cutting. Whether working with metals, plastic, or fragile materials, optimising the way they’re cut can lead to significant cost savings, reduced waste, and further carbon-neutral practices. This guide explores the key strategies for maximising material efficiency in profile cutting, and how leveraging cutting-edge technology assists in improving operation productivity and sustainability.

Understanding the Role of Metal Profiling

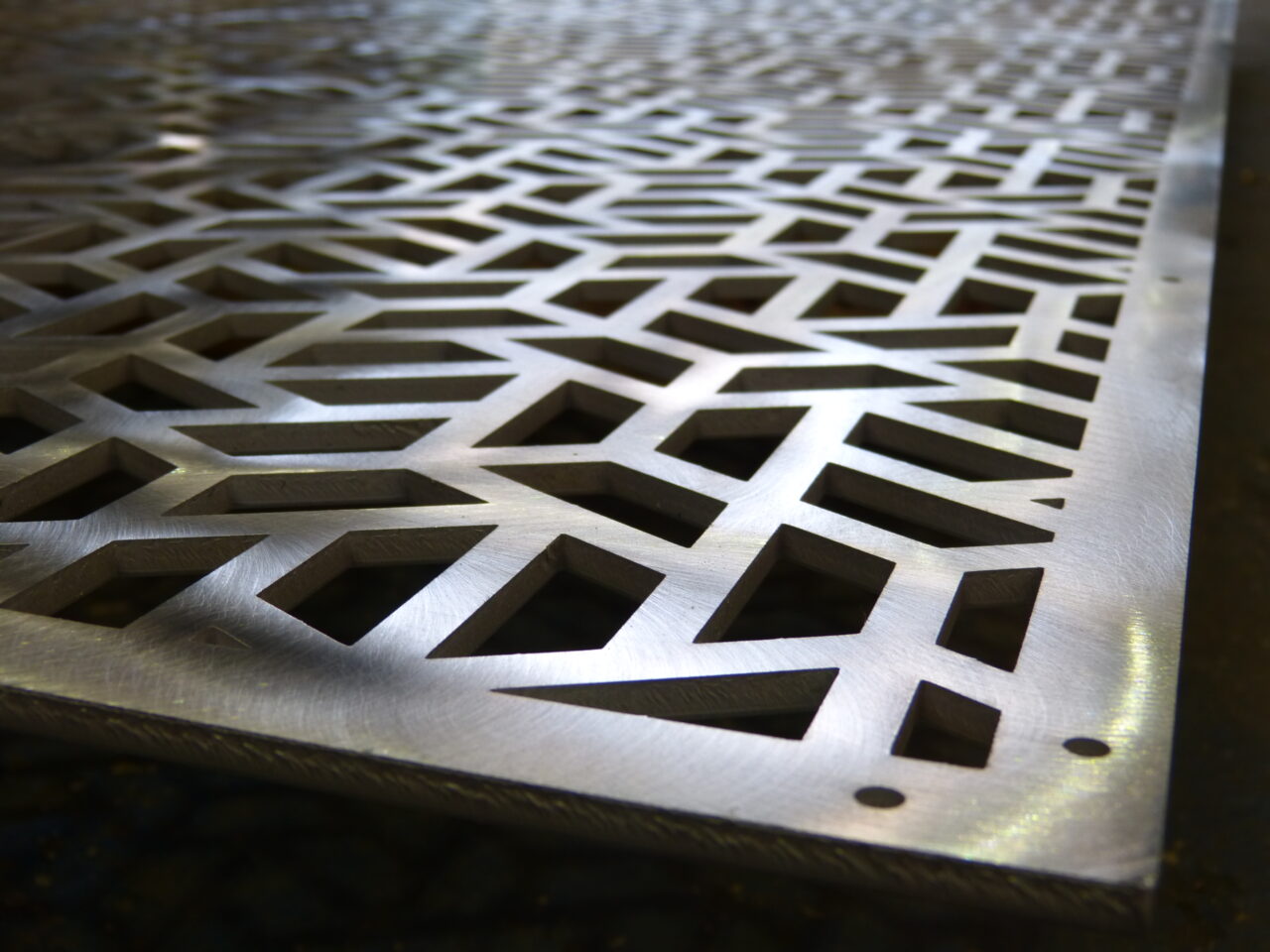

Profile cutting is a process that is used to cut a broad range of materials into specific shapes or profiles that are utilised across a variety of applications. This is essential in industries such as automotive, aerospace, construction, and manufacturing where precision and intricate detail are essential.

Methods like laser cutting, plasma cutting, and water jet cutting are commonly used to help achieve the desired design and shape, each offering unique benefits dependent on the material type, finish and, complexity of the project. Profiling services have adapted over recent years, offering more innovation and scope of capability, but there are challenges when navigating material waste and expenses, which puts efficiency as one of the forefronts of the process.

The Importance of Material Efficiency

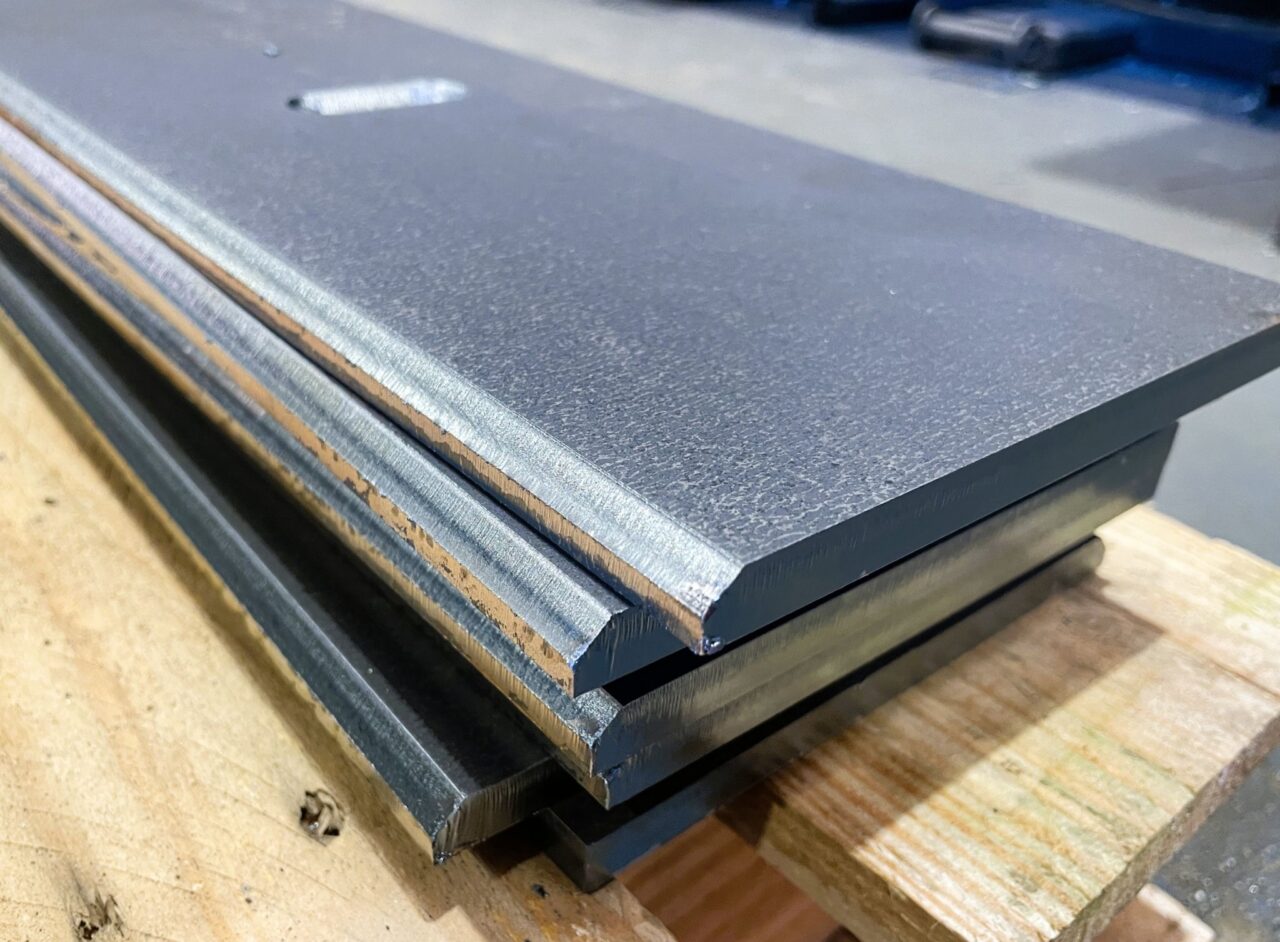

Optimising material efficiency in profile cutting is essential for both economic and environmental purposes. Waste in profiling not only drives up the cost of material procurement but also leads to an increase in energy consumption. This is because material expenses are one of the largest overheads for manufacturers to invest in, so effectively minimising waste also establishes greater savings.

Alongside this, sustainable practices are becoming the standard across industrial sectors, with the UK committing to be net zero by 2050, more initiatives and regulations are being set in place that futureproof profiling solutions from negative impact. Therefore, utilising technology that reduces waste also helps businesses and the profiling sector to encourage green practices, comply with evolving legislation, and be at the forefront of sustainability.

Strategies to Optimise Material Efficiency

Maximising material efficiency in profile cutting utilises a combination of streamlined production planning, advanced technology, and practical techniques.

Nesting

This technique involves arranging material on the flatbed to ensure space efficiency is at its most optimal layout. This is often utilised with smart software such as CAD systems to identify the best configurations and retain the greatest yield from each metal sheet.

Advanced Cutting Techniques

Utilising the right technology can significantly enhance efficiency in profile cutting, with laser cutting technology leading the way. Highly powered lasers deliver precision within tight tolerances, minimal kerf widths, and create intricate designs. Plasma and waterjet cutting also offer several benefits, with both methods greatly reducing the risk of heat-sensitive materials from warping, therefore maintaining important structural integrity.

Cutting Parameters

Customised specifications can be set depending on the needs required, which can lead to fewer errors and aim to retain as much material as possible. Such configurations can include cutting speed, feed rate, and power levels to minimise distortion, reduce kerf and, provide cleaner cuts.

Sustainable Solutions

It’s becoming more commonplace for manufacturers to make profiling more cost-effective by recycling and reusing offcuts. Smaller remnants from a project can often be repurposed for future jobs, while material tracking systems and scrap recovery are becoming normalised to ensure waste is turned into a valuable resource. These combined strategies help build a cutting process that is not only precise but also cost-effective and environmentally conscious.

Reduced Post-Processing Times

Reducing time spent on additional post-processing is a key strategy in maximising material efficiency. By ensuring cleaner cuts through precise nesting and selecting the right cutting method for the material, manufacturers can minimise the need for secondary operations such as grinding, deburring, or reworking, saving both time and resources.

Best Practices in Metal Profiling

Maximising material efficiency in profile cutting begins with applying best practices throughout the process to enhance downstream efficiency. Utilised alongside smart CAD software for optimal layouts, accurate nesting is essential for ensuring parts are used to their full potential with minimal waste.

Consistent inspections and re-investment of cutting equipment also play a key role, with well-maintained systems producing cleaner cuts and reducing the need for secondary processing. Operators should be trained to understand the properties of different materials and how cutting speed, temperature, and feed rates can affect the finished quality.

Reviewing previous projects and using them as educational resources is invaluable to the continuous growth of industry processes. By combining technology with experience, businesses can significantly improve efficiency, reduce costs, and minimise waste in metal profiling operations.

Achieve Maximum Efficiency With Charles Day Steels

Charles Day Steels provides leading profiling services, delivering high-quality and precise mechanical, waterjet, flame, plasma, and laser cutting solutions for all projects, regardless of scale and complexity.

Our expansive portfolio encompasses dynamic, precise and high-quality results for optimal material efficiency. As we continuously invest in the latest innovative technology, we are proud to deliver accuracy that is both compliant and sustainable.

If you require metal profiling in rapid lead times, speak to a member of our team today for a no-obligation quote.