Quick Links

Key Points:

- ISO 9001:2015 ensures consistent quality across all projects through standardised processes.

- Supports accuracy, consistency, and traceability at every production stage.

- Meets strict tolerances in sectors such as aerospace and medical device manufacturing.

- Promotes regular audits and refinement of processes to maintain high standards.

What Is ISO 9001:2015?

ISO 9001:2015 is a globally recognised standard for quality management systems (QMS), focusing on principles such as customer focus, leadership, process-based approaches, and continuous improvement.

The criteria set out help guide companies within manufacturing to achieve a well-structured formula that maintains consistency, precision, and efficiency across products and services. Achieving ISO 9001:2015 showcases a cohesive approach to quality management and great efforts towards customer satisfaction.

What Does Metal Fabrication Entail?

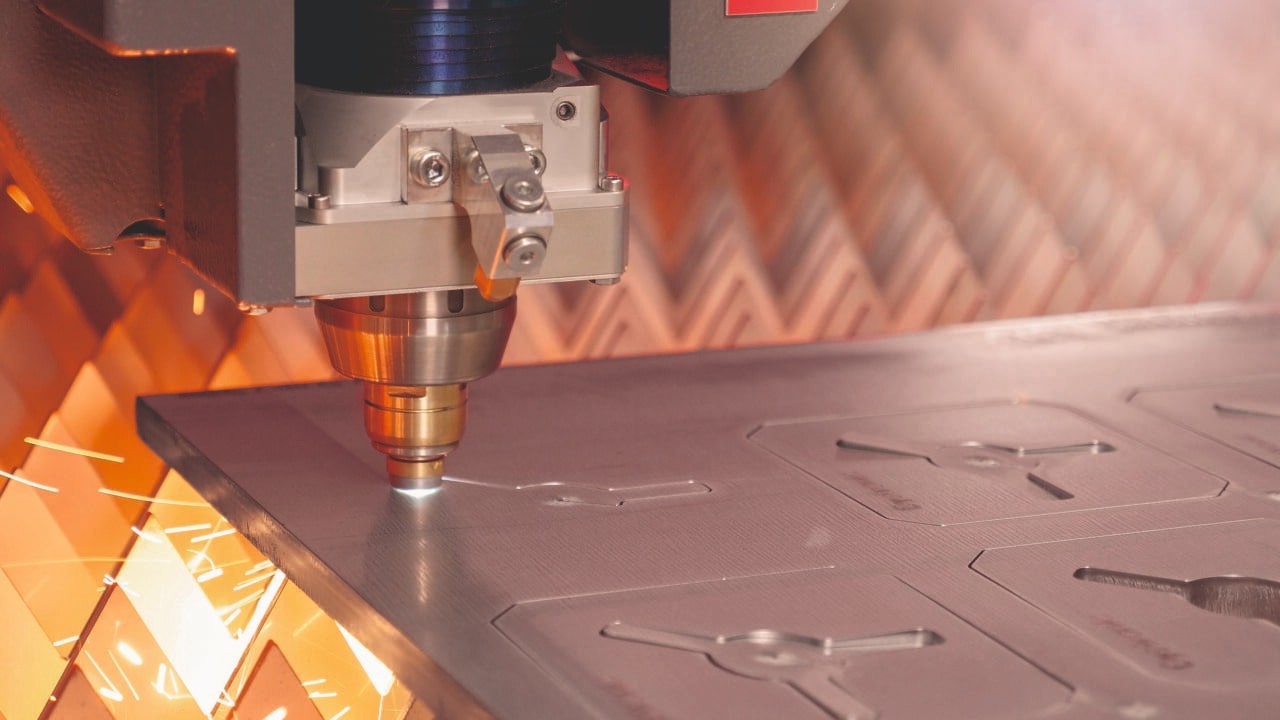

Metal fabrication, also referred to as profiling, involves the process of sourcing and assembling raw materials into components or finished products based on a client’s bespoke needs. This requires cutting, forming, and prepping materials in a variety of processes, such as:

- Smart design production and nesting

- Laser cutting

- Bevelled and weld-prepped parts

- Pre- and post-finishing

- Bending and pressing

- Aftercare inspection and delivery

Within precision-led industries, every step of the pipeline must meet stringent quality and traceability standards, which is further supported by ISO 9001.

How is ISO 9001 Obtained in Metal Fabrication?

To achieve ISO 9001:2015 certification, a metal fabrication business must implement and maintain a reliable and robust quality management system that follows the framework set out. The determining qualities include:

- Mapping out and documenting all operational processes

- Demonstrating effective leadership and planning

- Establishing clear quality objectives

- Regularly monitoring, measuring, and analysing performance

- Conducting internal audits and management structures

- Be approved by an accredited external body

Retaining ISO 9001:2015 accreditation requires ongoing commitment to the continuous improvement of processes while adhering to best practices.

How ISO 9001 Applies to Metal Fabrication?

In the laser cutting and metal fabrication sector, quality assurance and precision are critical processes. ISO 9001 ensures that every part of the process, from quoting to aftercare, follows defined procedures and quality controls. This can be applied to laser cutting processes in the following ways:

- Maintain consistent cut accuracy and finishes

- Documented workflows across quoting, CAD design, and inspection procedures

- Full material traceability and visibility

- Waste reduction through continuous quality control

- Material acquisition should be sourced from reliable suppliers

For sectors that rely on fine tolerances and a high level of accuracy, such as aerospace, automotive, construction, and medical, ISO 9001 provides the framework that helps manufacturers consistently deliver to high specifications.

The Benefits of ISO 9001

Implementing ISO 9001 principles delivers measurable advantages for both internal teams and customers:

Operational Efficiency

Streamlined and structured processes reduce waste, minimise errors, increase productivity, and enhance workflows.

Product Quality

Standardised procedures fulfil consistent results, irrespective of complexity or scale.

Customer Satisfaction

Certification provides assurance that the business operates to a high level of quality, establishing confidence and trust.

Risk Mitigation

Planning preventative action helps mitigate potential issues which could cause production delays and affect the overall outcome.

Competitive Advantage

ISO 9001:2015 sets companies apart in the industry, reinforcing reputation when it comes to quality and professionalism.

Achieve Exceptional Quality with Charles Day Steels

At Charles Day Steels, we are proud to be ISO 9001:2015 accredited, demonstrating our consistent approach to achieving high-quality results for all our customers’ bespoke needs.

We facilitate a wide range of laser cutting and additional services, from bevelling and countersinks to deburring, and we can assist any industry with their fabrication needs within exceptionally fine tolerances.

If you’re looking for metal profiling that maintains a high-calibre of finish, then speak to a member of our team today for a no-obligation quote.