Key Points:

- Stainless steel is incredibly corrosion-resistant, but can still be susceptible to tarnishing under adverse conditions.

- Routine maintenance is key when effectively managing light tarnishing.

- Advanced treatments such as shot blasting and laser cleaning are recommended for more stubborn areas of concern.

- Ongoing care and inspections are crucial to maintain the metal’s appearance and structural integrity.

Stainless steel is an incredibly popular, versatile and tensile metal, particularly renowned for its corrosion resistance. Utilised across both industrial and domestic applications, stainless steel is a valuable resource across a wide range of purposes. However, tarnishing can still occur with improper care or within adverse environmental conditions. As experts in handling and laser cutting stainless steel, we understand the importance of material maintenance, which is why at Charles Day Steels, we have curated a detailed guide on how to maintain the quality of stainless steel.

Why Does Stainless Steel Tarnish?

Although stainless steel is highly resistant to tarnish, it can become more vulnerable under certain conditions. Tarnish occurs when the chromium content oxidises, which can be the result of high moisture, harsh chemicals, improper cleaning, or special pollutants within the atmosphere.

In these situations, the protective oxide layer formed on the stainless steel can be stripped away due to repeated exposure, particularly over long time periods. Any damage, such as scratches, can also accelerate this process.

Signs of tarnishing:

- Yellow-brown discolouration

- Imperfections on the surface layer

- Areas that have lost their shine and gone dull

Traditional Methods of Maintaining Stainless Steel

For light tarnishing and regular maintenance of stainless steel, several popular methods can be used. These include:

Soap and Water

Although water seems contradictory to combat tarnishing, it is helpful in maintaining a clean surface for routine cleaning. Be sure to wipe down with a dry cloth when complete.

Baking Soda

Creating a paste out of baking soda can form a mild abrasive, which is great for tackling surface-level tarnishing on stainless steel.

Vinegar or Lemon Juice

The acidity from these methods helps to dissolve mineral deposits or water spots, ensuring that buildup does not occur and contribute to tarnishing.

Stainless Steel Cleaners

Specialised chemicals on the market can be used to help remove areas of concern on stainless steel, without compromising the rest of the metal.

Advanced Stainless Steel Cleaning Solutions

Additional treatment may be required in certain situations where traditional methods are not beneficial. Alternatives can be applied when the metal displays characteristics, such as:

- Heavy discolouration or oxidation

- Large surface contamination from industrial environments

- Cleaning intricate or laser-cut parts

Advanced preventative techniques can include:

Passivation

Passivation is a secondary process that is applied to stainless steel post-fabrication, intending to enhance corrosion-resistant properties and mitigate the effects of tarnishing. It works through an acid solution, such as nitric or citric acid, that removes any surface contaminants and stimulates the formation of an oxide layer. This layer serves as a protective barrier against any risk of further corrosion.

Industrial Solvents

Although acid-based cleaners are a popular choice, other solvents can also be utilised to achieve a clean finish on stainless steel. These include isopropyl alcohol, acetone, methylated spirits, xylene alcohol, and mineral spirits. They work to remove stubborn oil and grease from the metal’s surface and avoid any discolouration.

Secondary Finishes

Additional processing can be applied to particularly stubborn areas on the surface of stainless steel. Commonly, this can come in the form of surface grinding, shot blasting, or sand blasting, which aims to restore an oxidised surface. Additional treatment may be required beyond this in order to restore the oxide layer and achieve the desired finish.

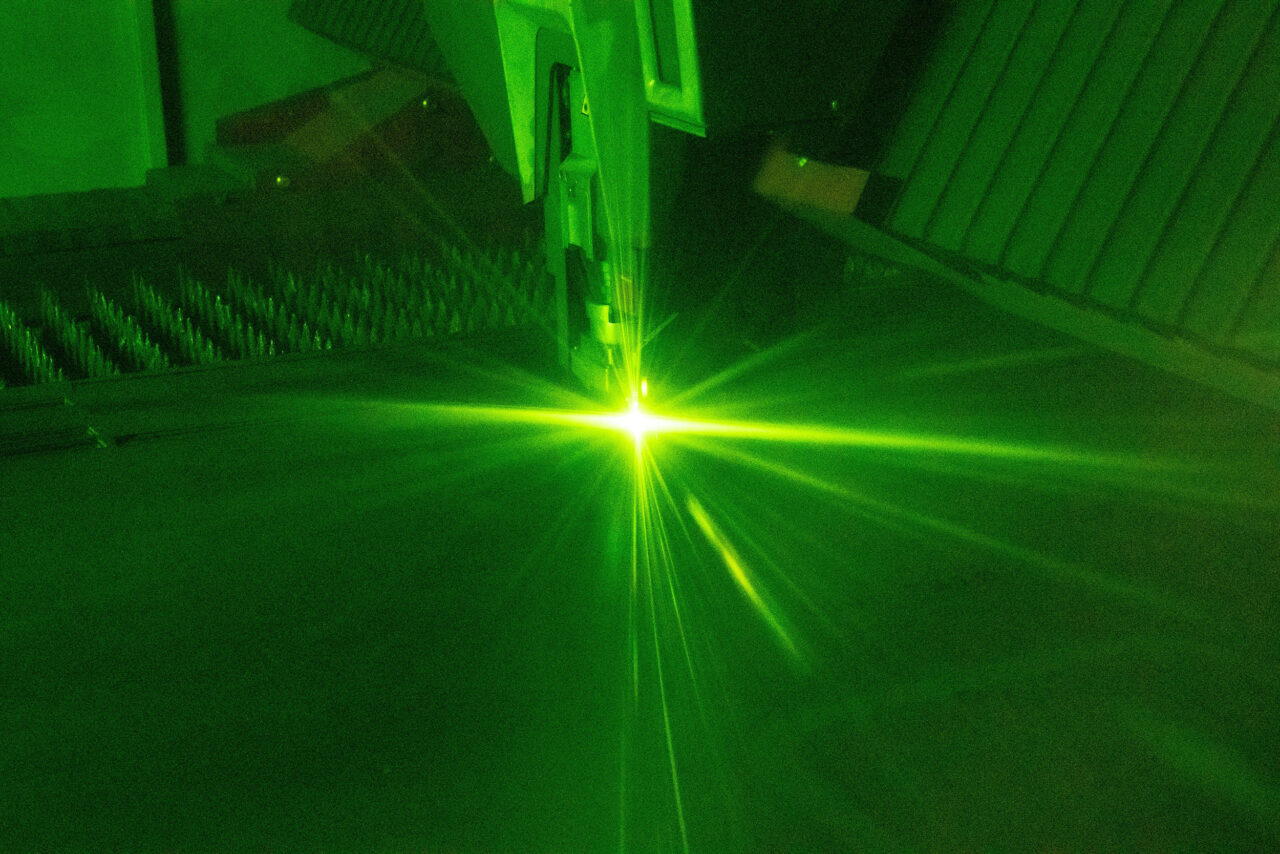

Laser Cleaning

The use of a high-energy laser can be used to effectively remove rust and tarnish from a metal’s surface layer. The laser beam works by heating and vaporising the tarnished area, leaving behind a clean surface. This is a non-contact process and can be used to spot-treat particular areas on the surface. Since this method does not rely on chemicals or organic matter, it is considered an environmentally friendly alternative.

How to Provide Ongoing Maintenance for Stainless Steel

It’s imperative to ensure routine care is carried out on stainless steel, therefore maintaining their lifespan and avoiding any unwarranted issues.

- Regularly wipe surfaces in the direction of the metal grain, preventing buildup and scratches.

- Wipe down and avoid prolonged exposure to chlorides, acids, or salt.

- Conduct routine inspections, particularly in industrial environments where structural integrity is critical.

- Consult with experts when requiring fabricated and laser-cut parts in order to apply the most effective finish to stainless steel, where required.

Procure High-Quality Stainless Steel With Charles Day Steels

At Charles Day Steels, we provide market-leading laser cutting and profiling solutions, ensuring every cut achieves an exceptional finish. Regardless of scale or complexity, we endeavour to provide quality components that are robust against the effects of tarnishing.

We store and facilitate a wide range of varying materials, from stainless steel, titanium or brass, complemented by our additional processes such as deburring and shot blasting.

If you’re looking for metal profiling that maintains a high-calibre of finish, then speak to a member of our team today for a no-obligation quote.