With our expertise and experience spanning over 4 decades, we here at Charles Day Steels acknowledge that the profiling of thick materials offers its own unique challenges. A common solution for processing thick steel materials, flame cutting offers numerous benefits; providing unmatched precision, economic advantages, superior finish quality, and more.

Unmatched Precision in Handling Thick Steel

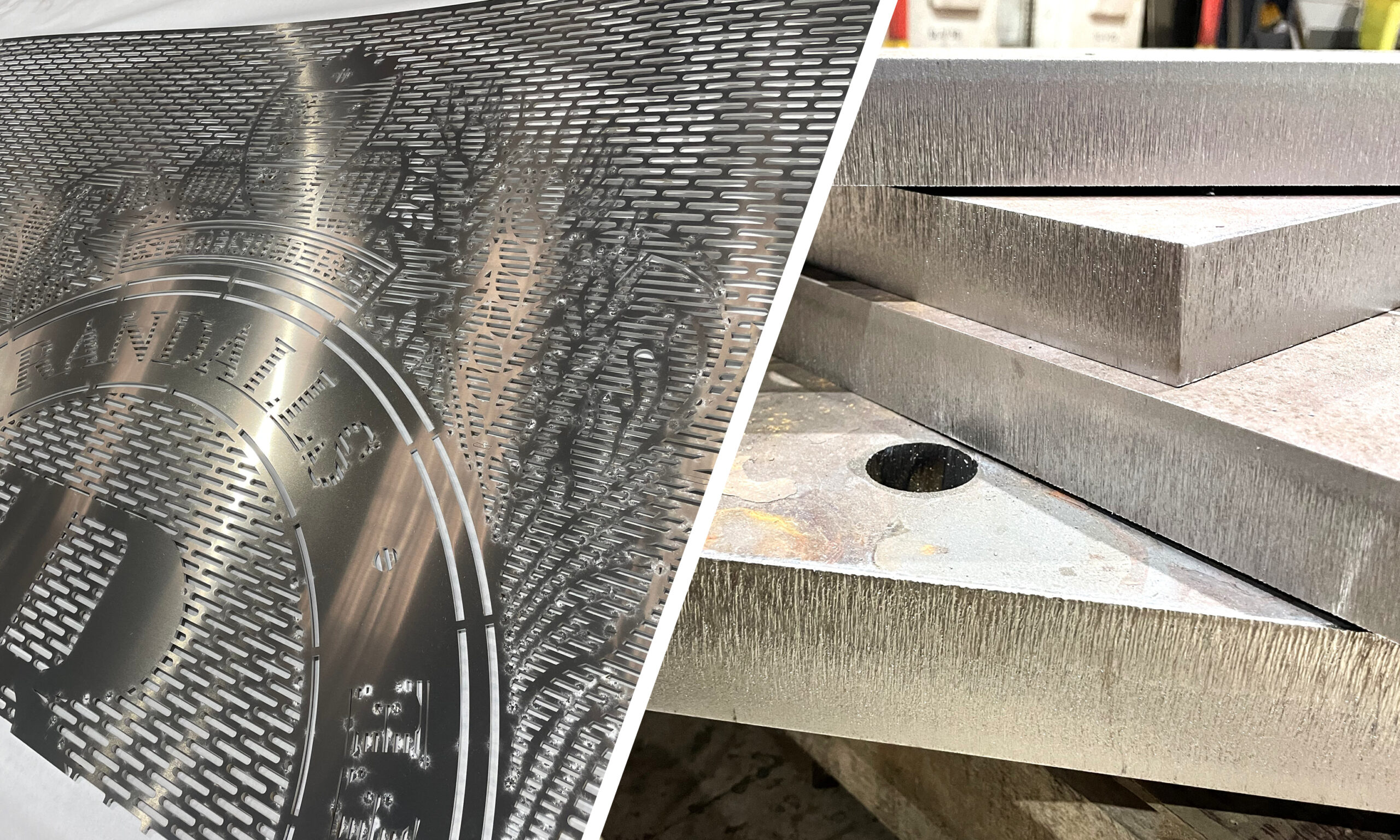

Flame cutting’s ability to precisely slice through steel materials up to 270mm thick is unparalleled. This precision is crucial for projects requiring intricate designs and exact dimensions. Flame cutting for thick steel materials is not only about maintaining the integrity of the design but also about ensuring that each cut meets stringent quality standards.

Economic Advantages of Flame Cutting

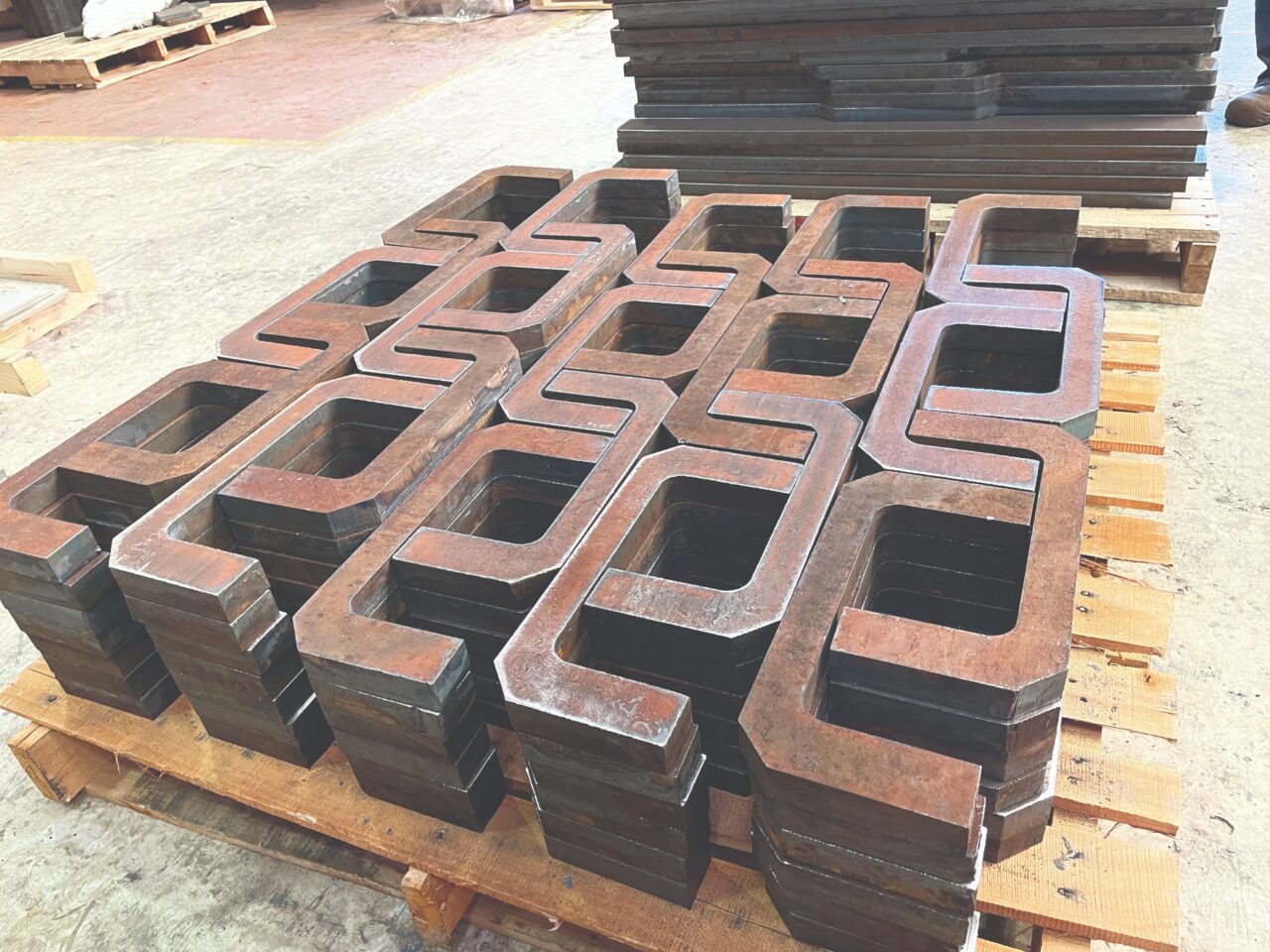

In terms of cost-efficiency, flame cutting prevails, particularly when large volumes of thick steel are involved. Its ability to handle extensive sheets and large quantities allows for a reduction in material wastage and operational costs. This efficiency makes flame-cut steel a viable option for businesses looking to optimise production while maintaining budget constraints.

Efficient Processing Speeds with Flame Cutting

The speed at which flame cutting processes thick steel is a significant advantage. Compared to other cutting methods, flame cutting can achieve faster processing times without sacrificing cut quality. This efficiency is crucial for projects with tight deadlines, making flame cutting a reliable method for maintaining production schedules.

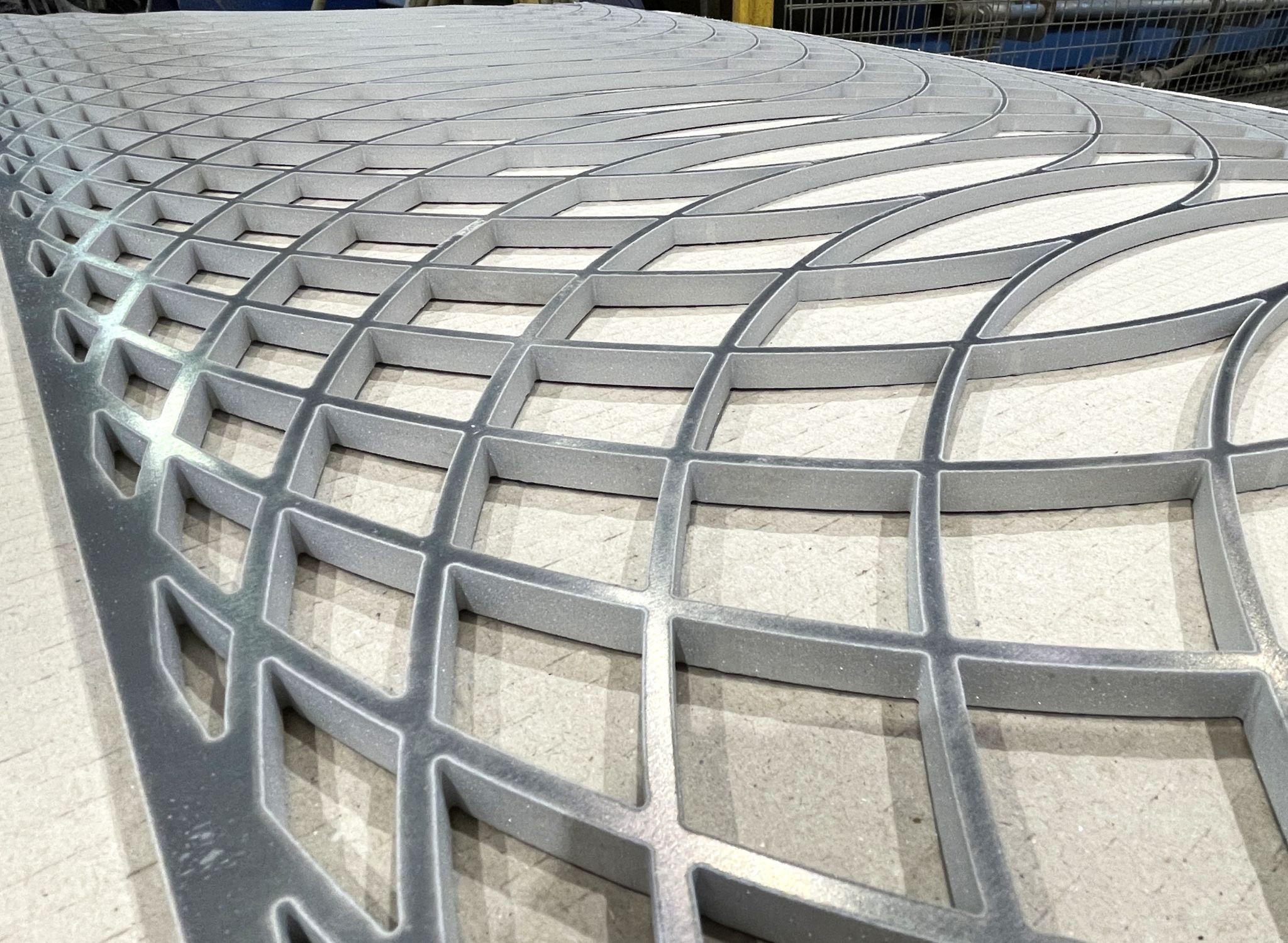

Versatile Applications Across Various Industries

The adaptability of flame cutting thick steel extends to numerous industries. This method is integral to sectors ranging from heavy construction to precision engineering, including aerospace and shipbuilding. Its versatility in creating both simple and complex shapes makes it an essential tool for fabricators.

Superior Surface Quality and Finish

Flame cutting is known for its high-quality surface finish. The method typically leaves a smooth finish, which is ideal for most applications. When flame cutting thick steel, any minor surface imperfections can be easily remedied with additional treatments, such as our Deburring Services, to ensure the final product meets exacting standards.

Sustainability and Environmental Considerations

Modern advancements in flame cutting technology have made it more environmentally friendly. These improvements have led to reduced emissions and increased energy efficiency, positioning flame cutting as a more sustainable choice in steel processing.

Technical Advancements in Flame Cutting

Recent technological advancements have further enhanced the capabilities of flame cutting for thick steel materials. The integration of computer-controlled cutting systems has improved the precision and speed of the process. These advancements allow for more intricate designs and tighter tolerances, making flame cutting an even more attractive option for complex projects.

Customisation and Flexibility in Design

Flame cutting offers exceptional customisation and flexibility in design. This method can be tailored to meet specific project requirements, from simple cuts to complex geometrical shapes. This flexibility is invaluable for projects that require a high degree of customisation.

Compatibility with Various Steel Grades

Flame cutting is compatible with a wide range of steel grades, including mild steel, carbon steel, and alloy steels. This compatibility ensures that flame cutting can be applied to a diverse array of projects, making it a versatile choice for different types of steel fabrication.

Skilled Workforce and Expertise

The execution of flame cutting requires a skilled workforce with specialised expertise. This expertise ensures that each project is handled with the utmost precision and care, resulting in high-quality outcomes. The skill and experience of the operators play a crucial role in the success of flame cutting for thick steel materials.

Contact Charles Day Steels For A Robust Solution for Thick Steel Fabrication

Flame cutting for thick steel materials is a robust and reliable solution in the steel fabrication industry. Its combination of precision, cost-effectiveness, speed, versatility, and quality, enhanced by technological advancements and skilled expertise, makes it an indispensable method. Whether for large-scale construction, detailed engineering projects, or specialised applications, flame cutting remains a top choice for professionals seeking the best in steel processing.

For professional flame cut steel parts, trust our experts at Charles Day Steels, and get in touch today.