Laser Applications in the Aerospace Industry

Aerospace is an expansive industry that demands unrivalled precision, stringent global requirements, and the ability to deliver lightweight, yet structurally resilient components. Safety and performance must be at the core of every application, adhering to incredibly tight tolerances while maintaining material integrity throughout the process.

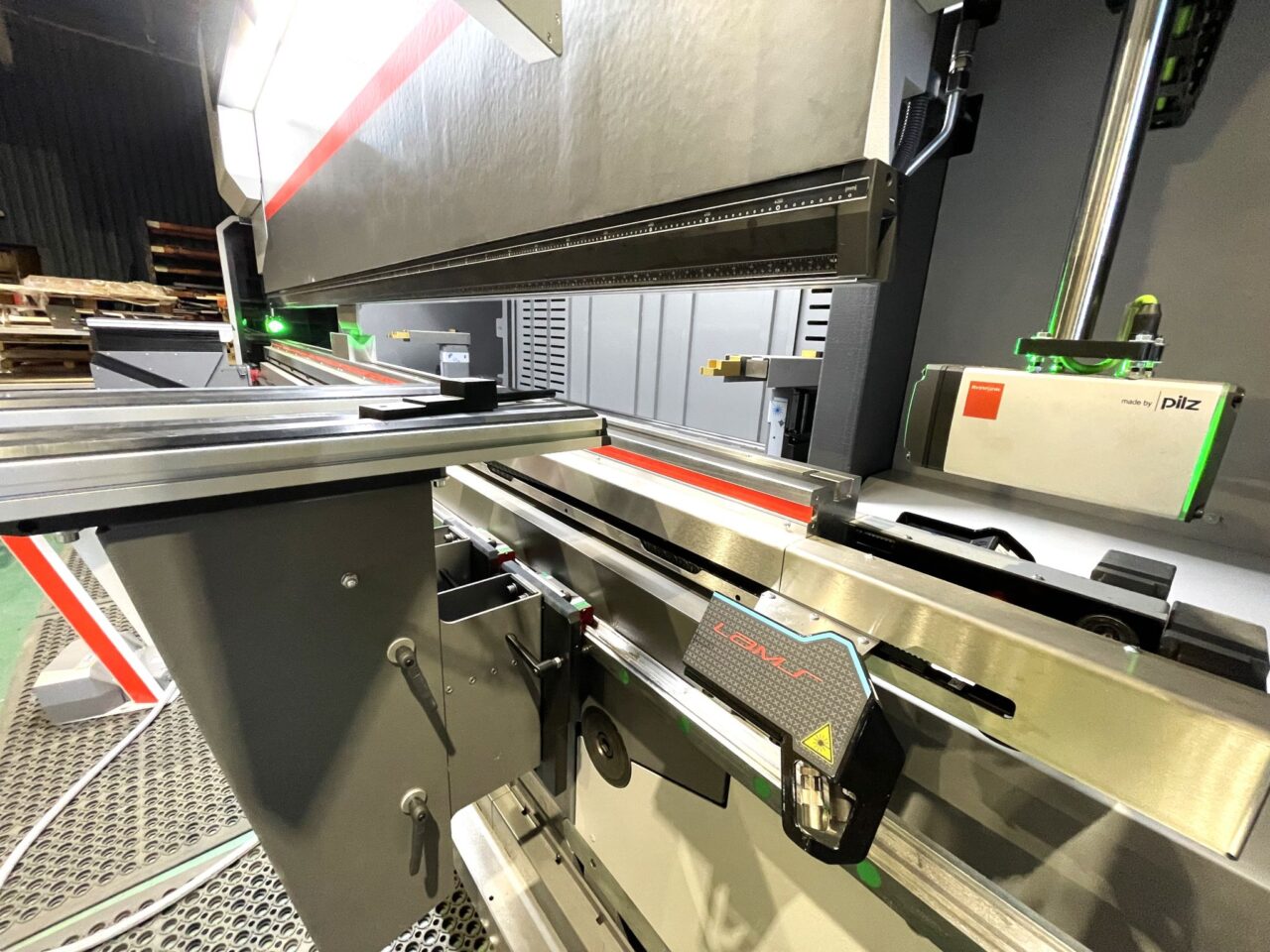

At Charles Day Steels, we are committed to delivering cutting-edge laser technology to facilitate commercial, defence, and space exploration in the aviation sector. Our flat-bed lasers can process a variety of aerospace-grade materials, from aluminium, stainless steel, titanium, and various alloys, capable of handling sheet sizes up to 6m x 2.5m with exceptional accuracy.

As market leaders in metal profiling, we understand the complexities of working with high-grade metals and their unique properties. Our precision-focused approach and ability to navigate complex challenges, such as reflective surfaces or heat-sensitive materials, make us a dependable partner in aerospace manufacturing.

Unrivalled Waterjet Bevel Cutting

Where precision and material integrity cannot be compromised, waterjet bevel cutting offers an invaluable solution. This cold-cutting process enables the rapid and accurate production of intricate or complex parts without encountering heat-affected zones, making it incredibly valuable in aerospace applications. Waterjet bevel cutting streamlines rapid prototyping and reduces the need for secondary processing, saving both time and expenditure.

Why Trust Charles Day Steels with Laser Cutting

Charles Day Steels is one of the UK’s market-leading profiling companies, with a strong commitment to reinvesting back into the latest technology, so our clients receive the highest level of quality laser cutting. With a solid foundation in sustainable manufacturing, our processes aim to revolutionise and future-proof industry processes, enhancing downstream processes and driving down overall expenses.

We’re proud to deliver a fully comprehensive range of in-house profiling services, including smart design production, bending and pressing, bevel cutting, and laser marking. We strive to exceed project expectations, with 24-hour production, competitive pricing, and stringent quality control.

Advantages of Laser Cutting in Aerospace

Laser cutting delivers extensive advantages in the aerospace industry, some of the key benefits include:

High Accuracy & Reliability

Laser cutting executes high-quality cuts within incredibly fine tolerances as required by engineers. Modern lasers result in remarkably clean cuts, mitigating the need for added processes such as deburring to achieve smooth finishes.

Rapid Procurement

The reliability of laser cutters can accommodate high throughput from initial design to the final component, minimising disruption along the pipeline. Scalable projects can rely on rapid turnaround with highly consistent results.

Minimised Waste

Introducing CAD design and advanced laser technology ensures that materials can be efficiently nested, minimising waste and eliminating costs, which is particularly critical for materials with a higher initial investment.

Versatile Design

Innovative laser cutting techniques can bevel cut complex geometries across 2D and 3D designs, while mitigating heat-distortion and the need for extensive additional processing.

Economic

Laser cutting outputs high-efficiency and smart technology to drive down material waste and energy consumption, while expediting lead times. Ultimately, achieving reduced initial expense and maximised profit.

Material Capacity

A wide range of materials can be procured for laser cutting with varying tensile strengths and challenging properties. If we don’t stock the material you require, it can be sourced in as little as 24 hours.

Laser Cut Applications in Aerospace Industries

Some applications of laser cutting in the aerospace industry include, but are not limited to:

Critical Components

Turbine blades, engine parts, wing and fuselage, fixtures, fasteners, brackets, panels, and hinges.

Laser Marking

Serial numbers, barcodes, QR codes, and batch data for traceability.

Welding

Bevel cut weld prep parts for lightweight and intricate components with minimal distortion.

Surface Treatment

Controlled and gentle removal of surface contaminants or oxides for effective surface preparation.

Plastic Parts

Interior fixtures, structural components, and prototyping.

Textiles

Insulation, composite, and interior furnishings.