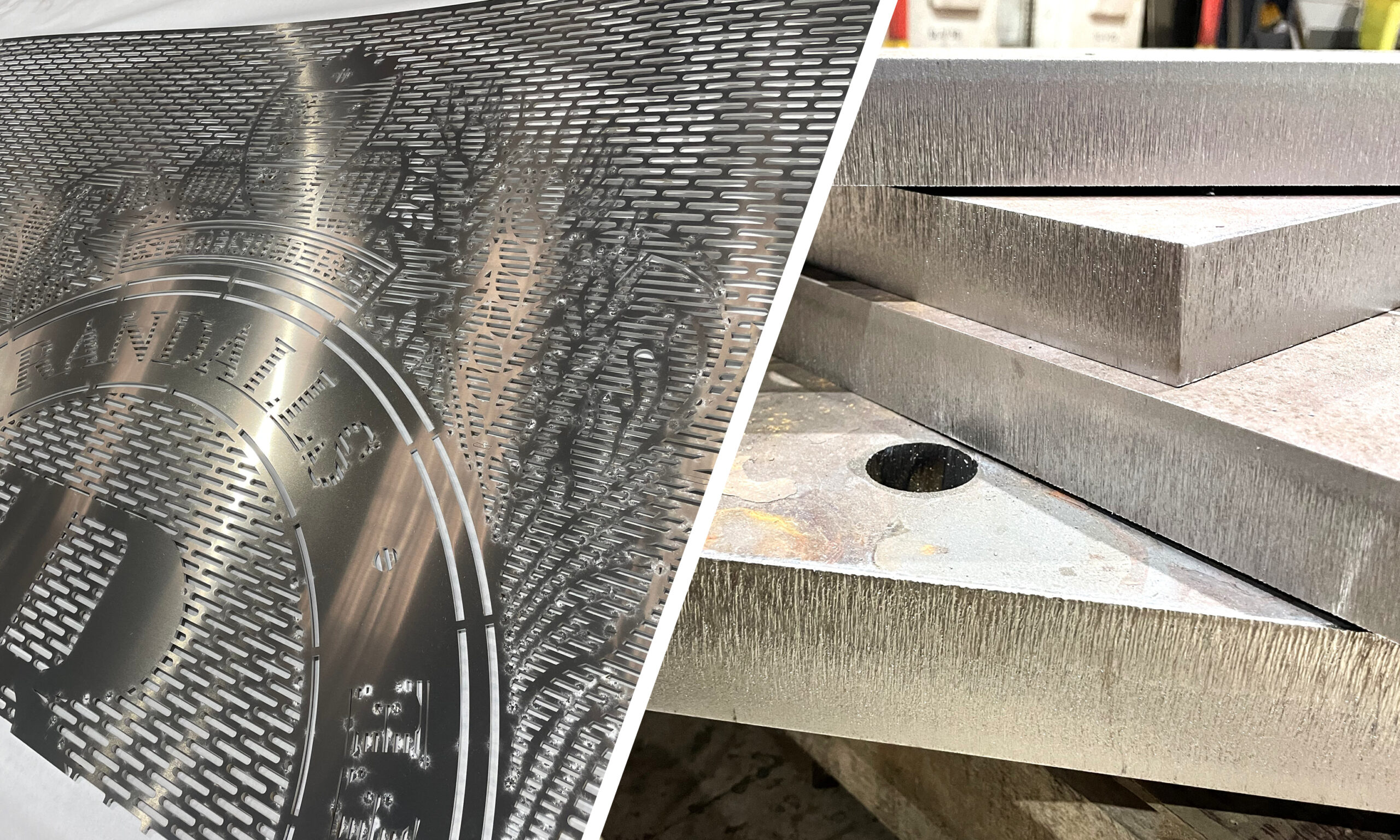

With over 45 years of combined industry experience, the team here at Charles Day’s are committed to providing profile cutting services to suit a range of industrial applications. With state-of-the-art technology and industry-defining capacities, Charles Day is proud to offer a diverse range of profile cutting services including our highly-praised HD Plasma Cutting service; a traditional, cost-effective, and reliable method of profiling carbon and mild steels, aluminium, and stainless steel up to 50 mm thick.

How Does It Work?

High Definition Plasma Cutting is the process of utilising a jet of ionised gas at temperatures exceeding 20,000 °C to melt and expel material to form the desired cut and works most efficiently on thicknesses between 3mm and 25mm. This jet expels pressurised gas (oxygen, air, inert, and more) at high speed, whilst simultaneously channelling an electrical arc through the flow of gas to transform it into plasma; this plasma reaches temperatures hot enough to cut straight through metal, whilst also maintaining a quick pace which allows the molten metal to be blown away from the cut.

What Are The Benefits Of Plasma Cutting?

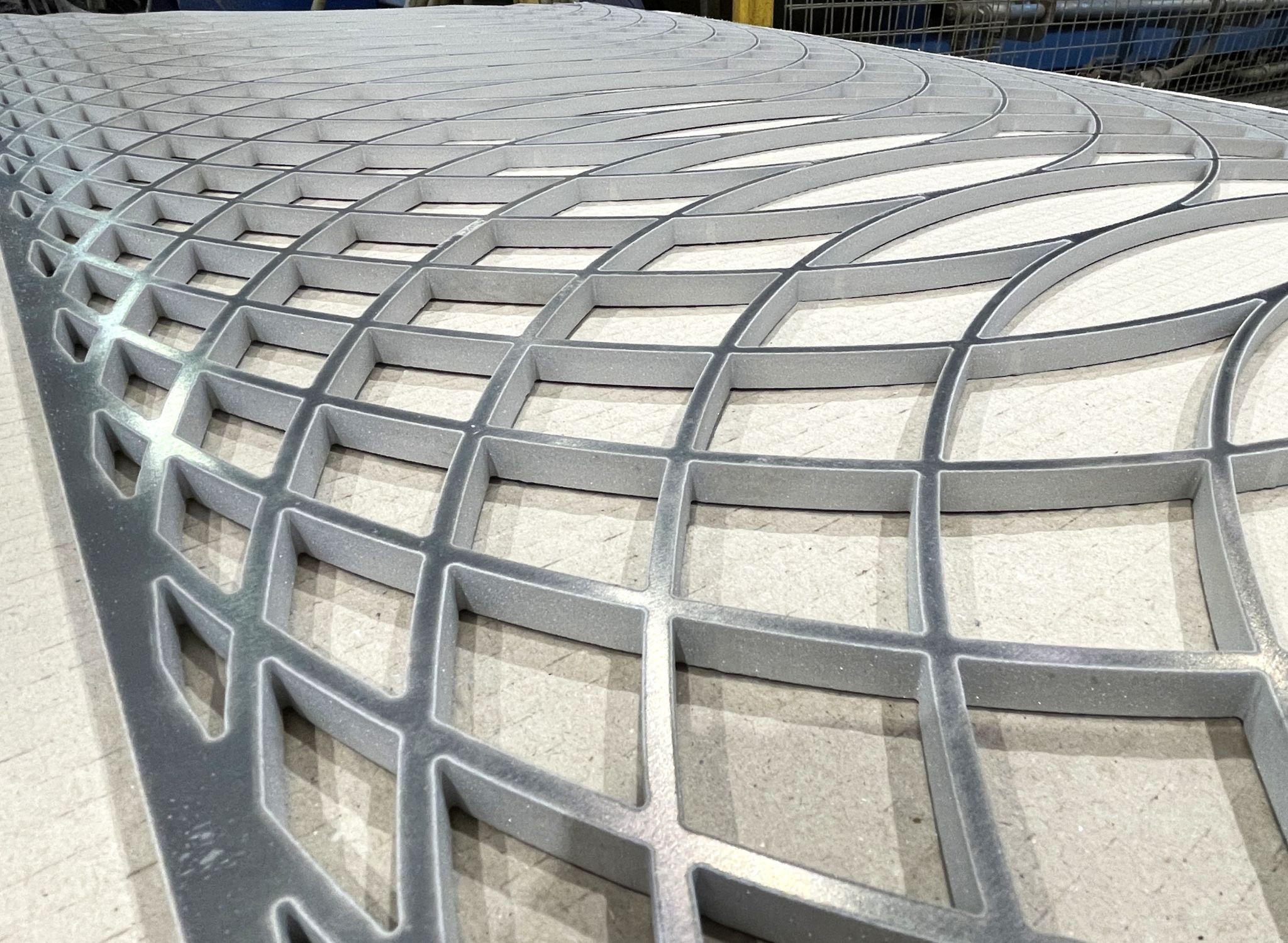

A traditional method of steel profiling, HD Plasma Cutting is considered to be a far more efficient process when compared to Flame Cutting. This is due to its ability to profile a wide range of materials including steel and aluminium, as well as a selection of carbon steels quickly and accurately.

A revolution in metal fabrication, HD Plasma Cutting is an extremely efficient approach to profiling steel and various other non-ferrous materials. Typically much faster than other methods, High Definition Plasma Cutting offers a smoother cut and finish, and is more efficient on non-linear cuts, whilst also being considerably more accurate and affordable when compared to various other metal processing procedures.

At Charles Day’s, we are committed to continuous reinvestment into the very latest and best metal profiling technologies. This dedication is to guarantee an exceptional product for the ultimate benefit of our customers, and with 24-hour production, we promise a quick and professional turnaround for the very highest quality profile cut parts.

What Materials Can Be Cut With HD Plasma?

High Definition Plasma Cutting is an excellent option for processing metal, and our in-house heavy-duty plasma cutters can process metal plates ranging from 1mm to 1 inch in thickness. With thickness tolerances in accordance with BS EN 10029:2010 Class A regulations and flatness tolerances in accordance with BS EN 10029:1991 regulations, Charles Day is dedicated to providing accurate, efficient, and reliable HD Plasma Cutting services for industries across the UK and Europe.

Offering an unparalleled edge squareness when compared to other methods of metal profiling, HD Plasma Cutting is more often than not the method of choice for most metal fabricators; this is due to its efficiency, affordability, and broad applications.

Some of the many materials that can be cut using a High Definition Plasma Cutter include €¦

- Mild steel

- Stainless steel

- Carbon steel

- Expanded steel

- Aluminium

- Copper

- Brass

- Other ferrous & non-ferrous materials

Contact Charles Day For Tailored HD Plasma Cutting Services

With a host of in-house, state-of-the-art metal profiling facilities, our professionals here at Charles Day Steel invest in the best and latest technology so that you don’t have to. With a plethora of professional services to select from, such as our HD Plasma Cutting, Flame Cutting, Profile Bending, and much more, it’s never been simpler to outsource your metal profiling to the experts. This, combined with our commitment to Quality Assurance, are just some of the many reasons why Charles Day has been one of the industry leaders for over 35 years.

For expert metal profiling services, get in touch with the team at Charles Day; our commitment to excellence is always guaranteed.