Precision and Versatility: The Charles Day Advantage

Metal fabrication has evolved significantly over the years, with technological advancements paving the way for more precise and efficient cutting methods. A powerhouse in the field of profile cutting services, Charles Day Steels stands at the forefront of these innovations.

Charles Day Steels offers a diverse range of cutting methods, each tailored to specific materials and project requirements. By seamlessly integrating these methods, we provide customers with unparalleled precision and versatility in metal fabrication.

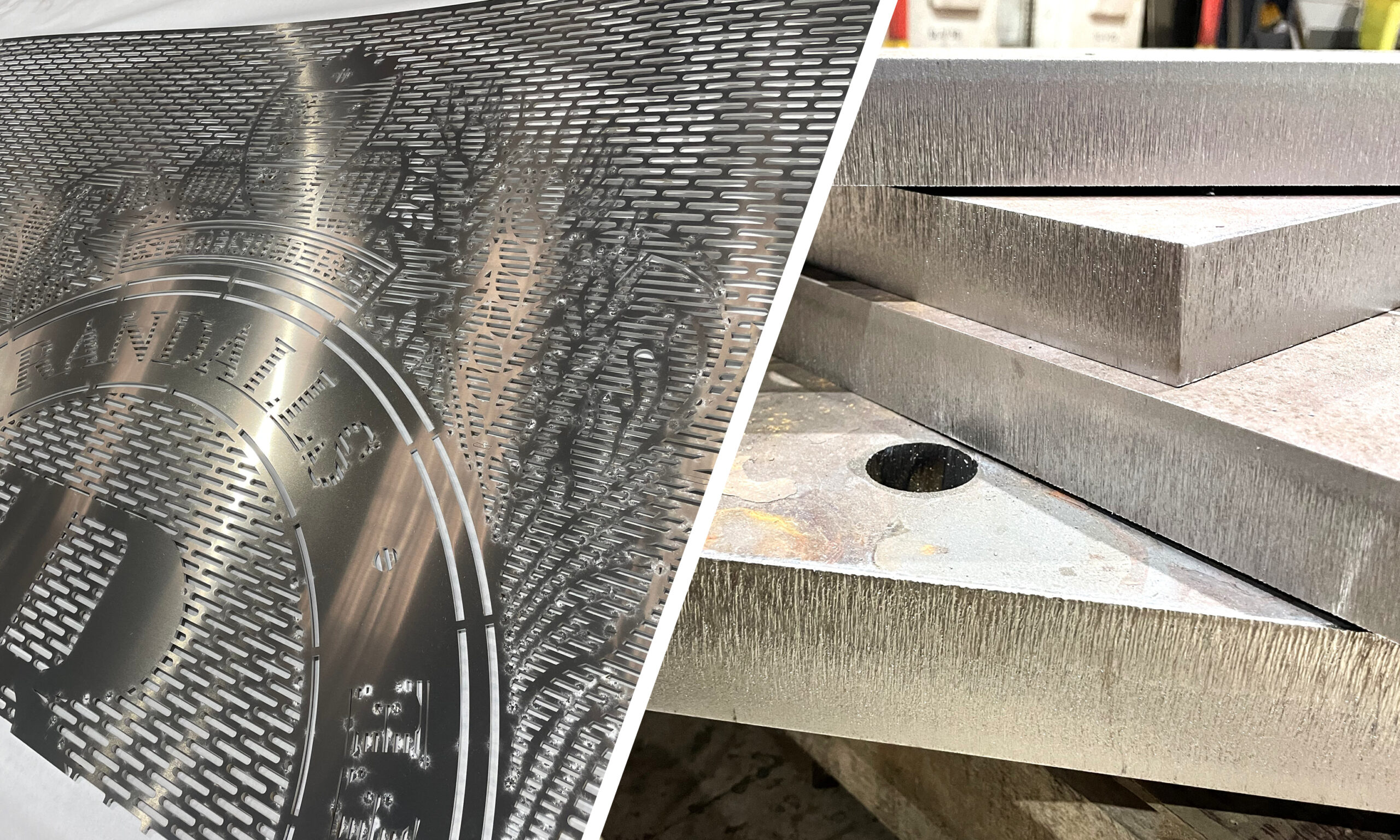

Laser Cutting for Unrivalled Accuracy

Charles Day’s suite of laser cutting machines, including the UK’s first 20kW fibre laser, ensures unrivalled accuracy in profile cutting. Laser cutting excels in delivering intricate designs and precise cuts, making it ideal for a wide range of materials, including steel, aluminium, stainless steel, copper, brass, and bronze. The precision offered by laser cutting is crucial for projects where intricate details and tight tolerances are non-negotiable.

Tube Laser Cutting for 3D Profiling

Our 6-axis 3D tube laser cutting service at Charles Day is a testament to our commitment to innovation. This method allows for fast and accurate profiling of round and square tubes, with in-process application of bevels and countersinks. Tube laser cutting is particularly advantageous in projects that demand complex 3D shapes and structures, contributing to the versatility of the overall fabrication process.

Waterjet Cutting for Material Diversity

Large waterjet cutting beds at Charles Day, measuring 9m x 4m, are equipped with powerful pumps that can accurately profile almost any material up to 230mm thick. Waterjet cutting is known for its ability to work with a wide range of materials, including steel, stone, carbon fibre, plastics, and more. This method is especially valuable in applications where a heat-affected zone must be avoided, such as in aerospace and nuclear projects.

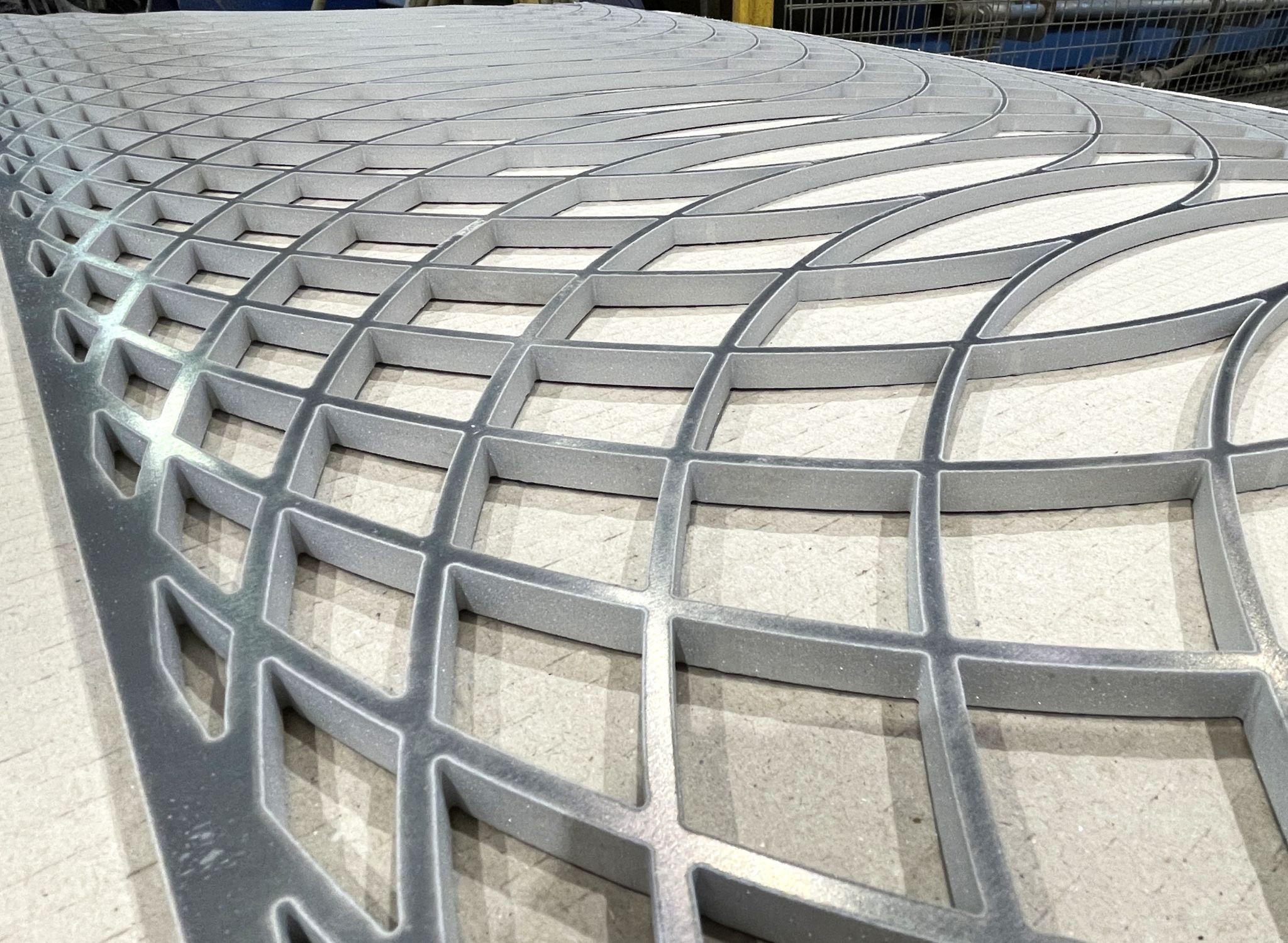

Waterjet Bevel Cutting For Advanced 3D Shapes

One of Charles Day’s newest investments in our long line of industry-defining metal profiling technology is the Waterjet Sweden BevelJet 60. Offering a 125hp pump for 6200 bar cutting, unbeatable production times, dual 3D and 2D heads, a cutting bed of 4m x 8.5m, and capable of processing 3D parts up to 60°, the Waterjet Sweden BevelJet 60 provides advanced 3D cutting of sheet metal, reduced production times, and improved dimensional quality for even the most complex of projects.

Flame Cutting for Efficiency in Production Runs

Charles Day’s flame cutting service is highly efficient for high-volume production runs, offering a cost-effective solution. With 8 cutting heads per machine and large cutting beds capable of profiling sections up to 22m x 5m, flame cutting is a go-to method for projects with short lead times. The method’s tolerance range of +/-2.0mm to +/-6.0mm (dependant on material thickness) makes it suitable for various thicknesses, contributing to its efficiency in large-scale production.

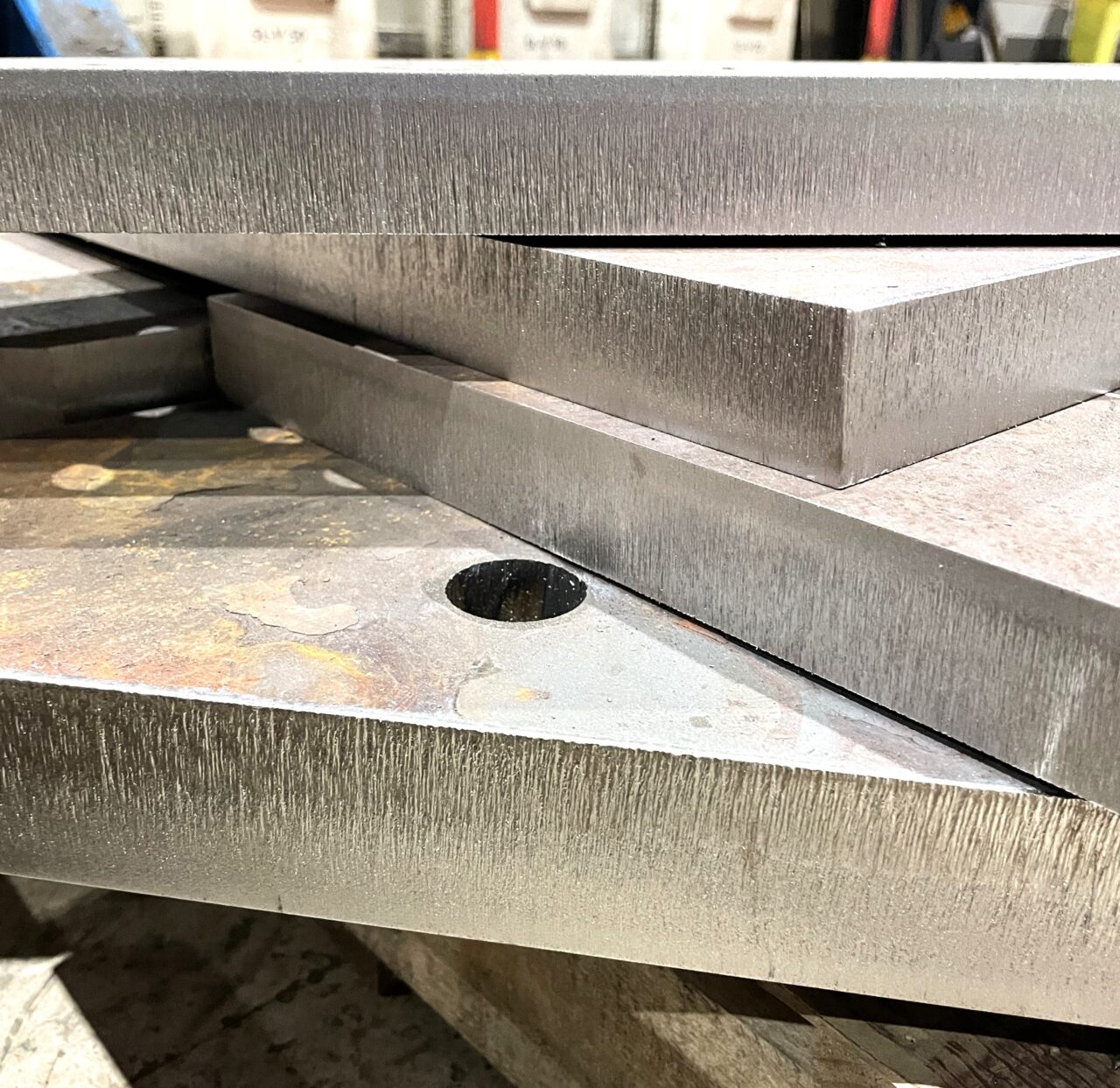

HD Plasma Cutting for High-Definition Profiling

High-definition plasma cutting is ideal for profiling stainless steel, aluminium, and carbon steels. Charles Day’s HD plasma cutting service, with a capacity of up to 12m x 4m, delivers maximum edge squareness and is suitable for parts measuring up to 12m x 5m. This method is particularly beneficial when precision is paramount, and the quality of the cut edge is crucial.

The Synergy of Combined Cutting Methods

The beauty of Charles Day Steels’ approach lies in the synergy created by combining these various cutting methods. This integration results in a comprehensive and versatile service that caters to the unique needs of each project. The benefits are as follows:

Optimised Turnaround Times

By leveraging the strengths of each cutting method, Charles Day Steels achieves rapid turnaround times. Whether it’s high-volume projects or those demanding intricate designs, the combination of cutting methods ensures that deadlines are met without compromising on quality.

Reduced Weld Preparation and Simplified Assembly

The use of multiple cutting methods allows for downstream efficiency. Additional profiling capabilities, such as chamfers and bevels applied during cutting, reduce the need for extensive weld preparation. This not only streamlines the assembly process but also contributes to the overall cost-effectiveness of the fabrication.

Flexibility in Material Selection

The diversity of cutting methods enables Charles Day Steels to work with a wide array of materials. From traditional metals like steel and aluminium to advanced materials like carbon fibre and plastics, the combination of cutting methods provides unmatched flexibility in material selection.

Quality without Compromise

The adherence to stringent quality standards, including BS EN ISO 9001:2015 and BS EN 1090-1:2009 +A1, ensures that the combination of cutting methods at Charles Day Steels never compromises on quality. Each method is applied with precision, resulting in finished products that meet the highest industry standards.

Contact Charles Day Steels For Comprehensive Metal Fabrication

In the dynamic landscape of metal fabrication, Charles Day Steels emerges as a leader by seamlessly integrating various cutting methods. Our commitment to precision, efficiency, and versatility is evident in the array of profile cutting services we offer. By combining laser cutting, tube laser cutting, waterjet cutting, flame cutting, and HD plasma cutting, we create a symphony of cutting capabilities that caters to the diverse needs of the modern fabrication industry.

For companies seeking a one-stop profiling shop that delivers value through capability, speed, and accuracy, Charles Day Steels stands as a shining example of how the strategic combination of cutting methods can redefine what is achievable in metal fabrication.