Pursuing Precision: Charles Day Steel’s New Waterjet Cutting Machine Investment

Committed to consistent reinvigoration, we invest in only the very best technology, machinery and materials available in the industry – all for the benefit, simplicity

Committed to consistent reinvigoration, we invest in only the very best technology, machinery and materials available in the industry – all for the benefit, simplicity

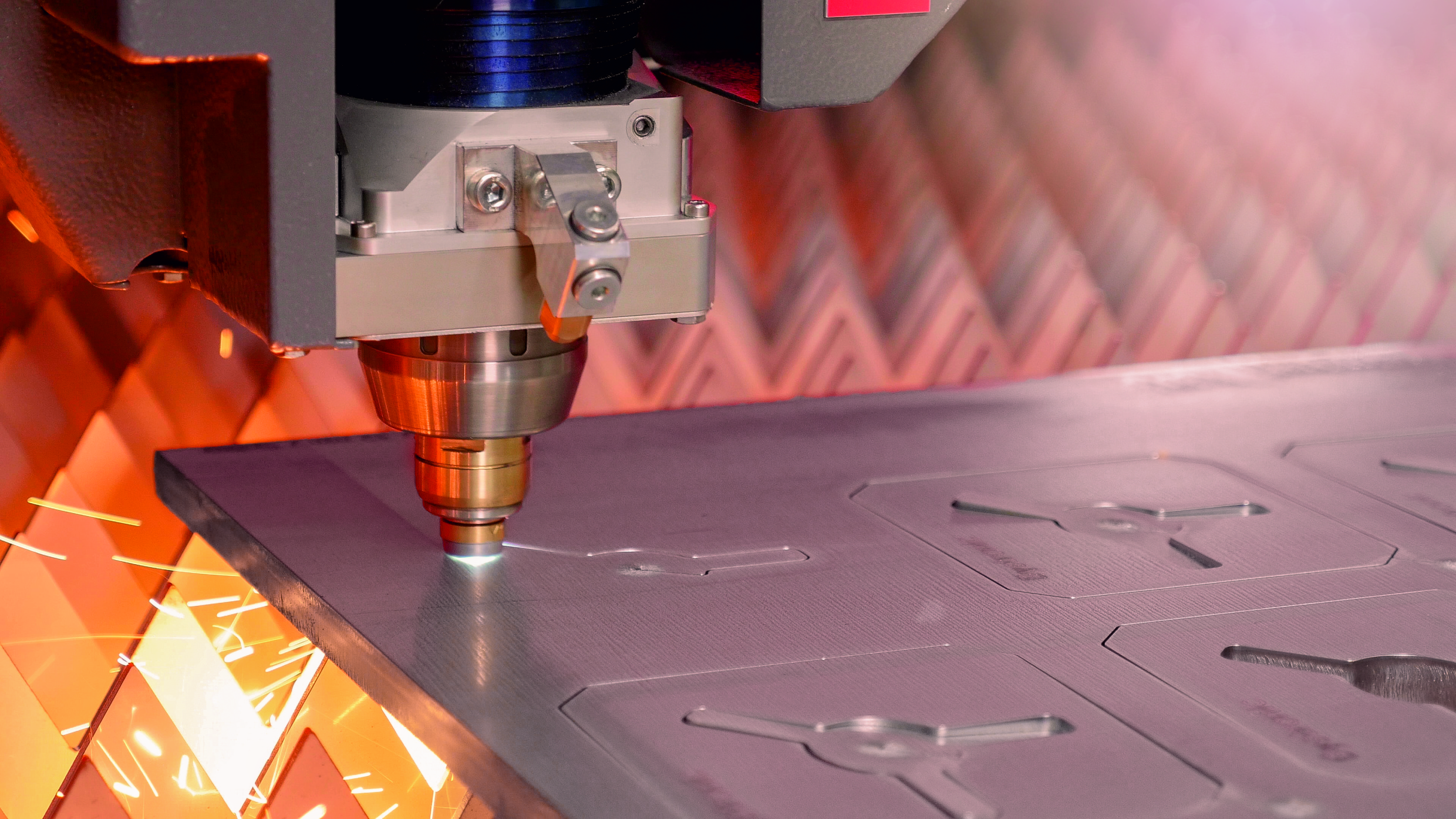

Here at Charles Day Steels, we provide a plethora of laser cutting services to meet a wide range of applications and requests. With an unrivalled laser cutting

With over 45 years of combined industry experience, the team here at Charles Day’s are committed to providing profile cutting services to suit a range

Flame cutting is a process that is used to cut through thick metal, predominantly mild steel. It is a process used in all types of

Laser cutting has come a long way since its inception in the 1960’s. 2D and 3D laser cutting are among several names used to reference

Waterjet cutting brings the accuracy and repeatability of computer control together with the power of high pressure pump technology. Advances in materials, control and pump

Outsourcing metal profiling is a solution to many challenges. One of the key benefits is that manufacturers can avoid the need to invest in and

The current situation in Ukraine is having a direct impact on the European steel market for a number of reasons. As such we see it

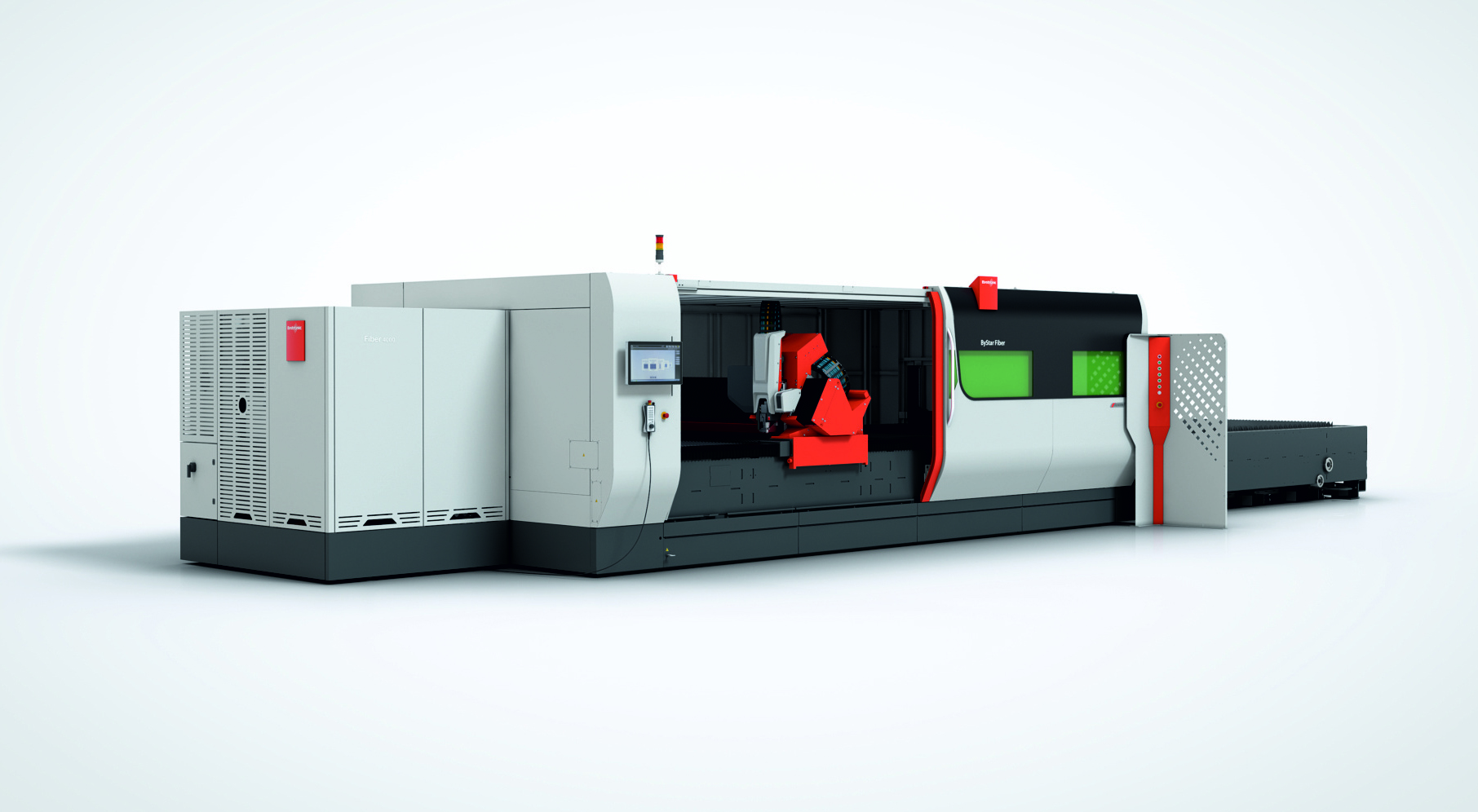

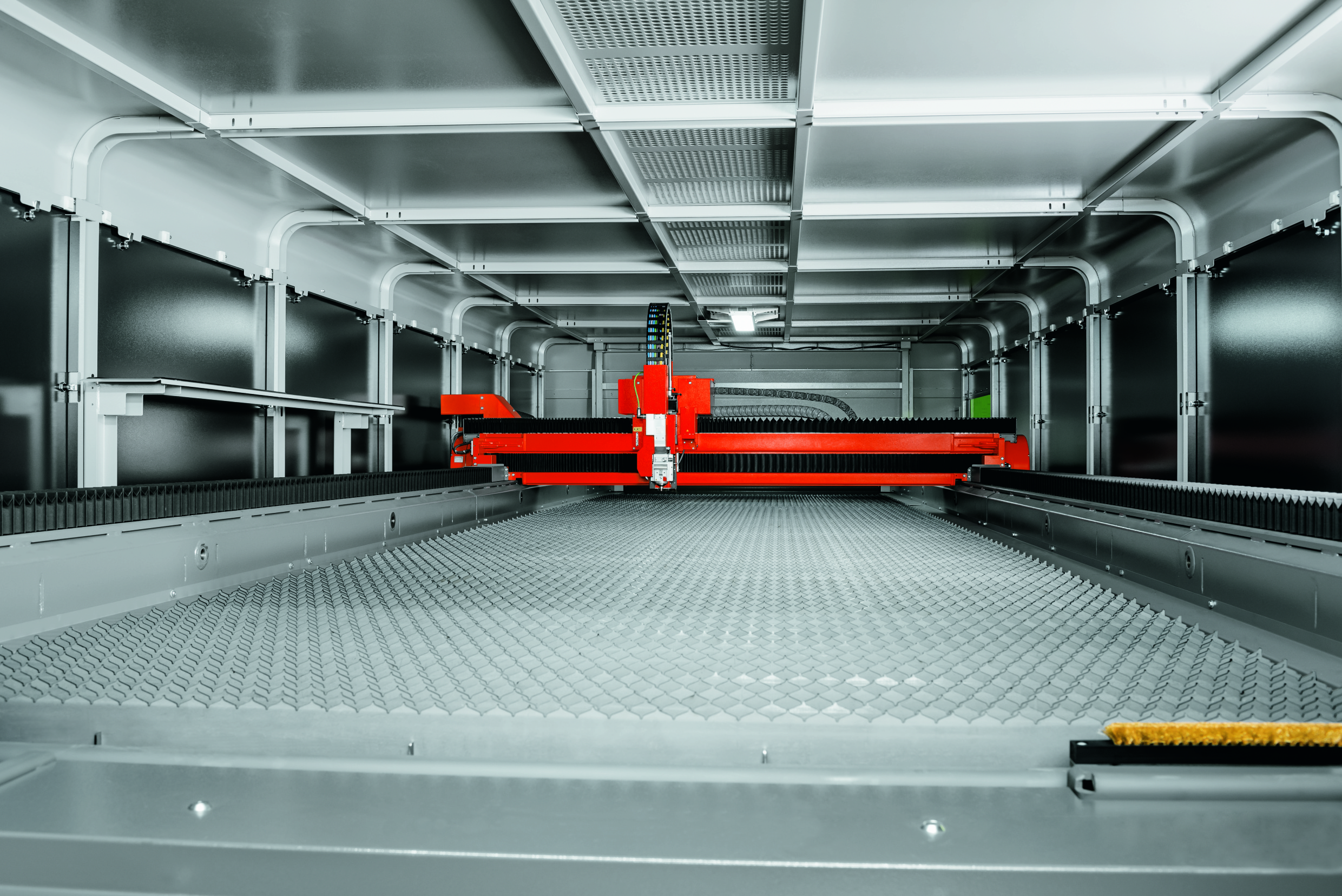

Continuous investment has always been key to Charles Day’s success and with their latest addition to the laser fleet, they show no signs of slowing

During these unprecedented times we are proud to reassure customers that we are open for business and fully operational having gained Key Supplier status subject

Everyone needs to be doing their bit to support the fight against the Covid 19 pandemic, this goes without saying and Charles Days is doing

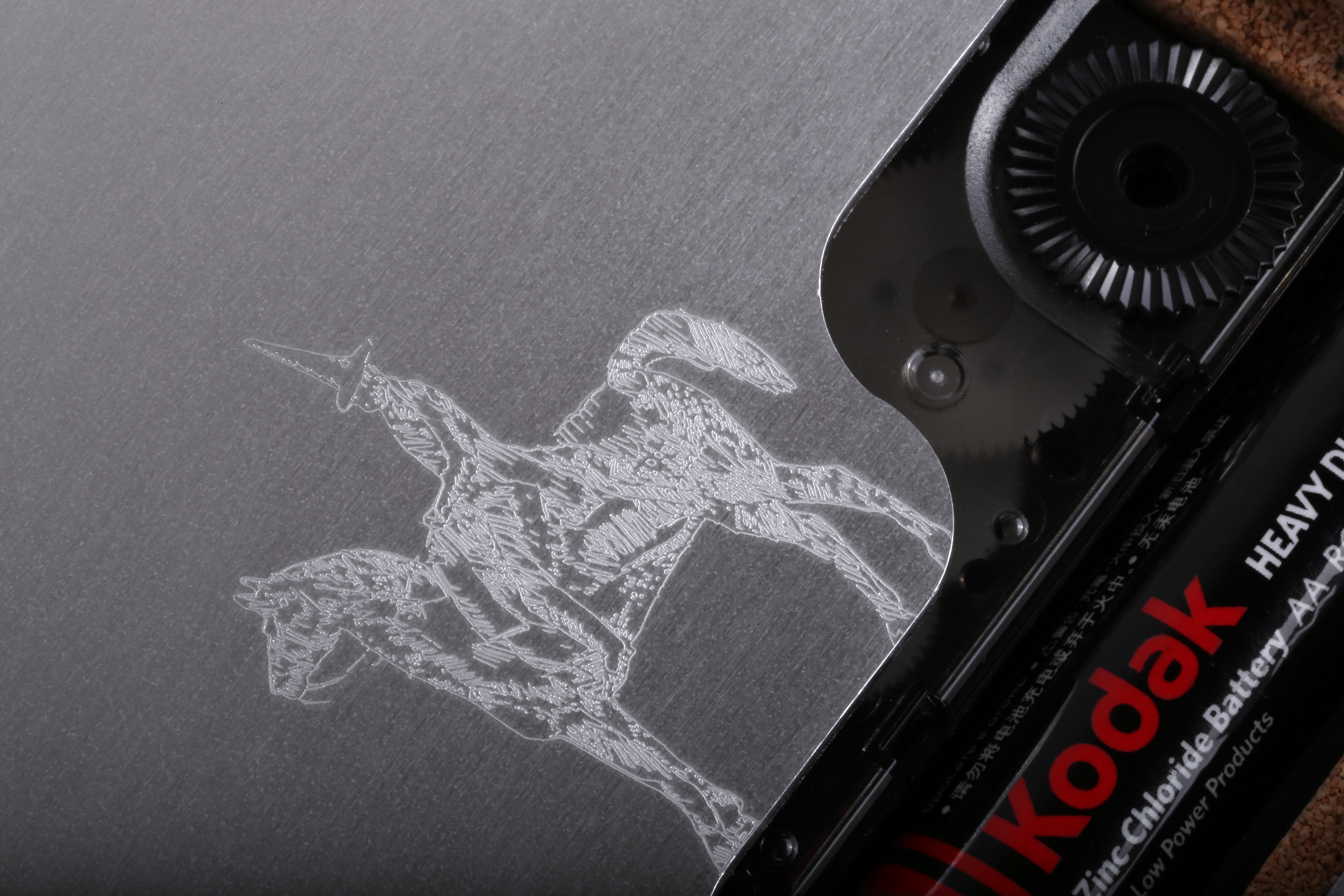

Paulin Watches were launching a new wall clock product range and needed a reliable and accurate laser cutting service, also capable of providing fine and

From 1976 Charles Day (Steels) has evolved into one of the largest and diverse specialist profile cutting companies in the UK.

Charles Day Steels,

6 Downgate Drive,

Sheffield, S4 8BT

Phone: 0114 244 5544

Email: sales@daysteel.co.uk

Website built by Fenti Marketing