Hardox steel is widely known for being one of the toughest, most abrasion-resistant steels available on the market. Suitably designed to perform in challenging environments, this particular metal type is often utilised across heavy-duty sectors, such as defence or construction. Armour and wear plates are particularly valued in protecting equipment from damaging impact, which requires them to be incredibly robust and maintain a long lifespan. This guide delves into the characteristics of Hardox steel and how it can be applied across industries, along with the essential role of advanced cutting technologies such as waterjet, waterjet bevel, and laser bevel.

The Unique Traits of Armour and Wear Plate Steel

The most defining property of steel, such as Hardox, is just how remarkably strong it is. A material’s strength can be determined by a Brinell hardness test, with Hardox steel achieving between 400 HB to over 600 HB with resistance to cracking and chipping, depending on the grade type. In comparison to traditional steel, which can achieve just over 400 HB, brittleness can come as a cost. This makes armour and wear plate steel extremely versatile, withstanding abrasion from the demands of mining or resisting ballistic impact with ease. It also features exceptional formability and welding characteristics, which allow for the steel to be formed into complex shapes and achieve a wide range of designs across various sectors.

However, this same strength also makes these steels incredibly difficult, time-consuming, and expensive to machine or weld post-cutting, especially with traditional tools. Advanced profiling, such as waterjet, waterjet bevel, and laser bevel, is critical in this instance, allowing the material to be processed within tight tolerances without causing distortion, cracking, or hardening.

Key Applications of Hardox Armour and Wear Plate

Industrial and Heavy-Duty Sectors

Construction and Mining: Heavy use in the bodies of trucks, crushers, hoppers, conveyor systems, and any equipment that is frequently exposed to consistent wear and impact.

Transport and Agriculture: This steel type offers lightweight and resilient capabilities for trailers, containers, ploughs, and any piece of equipment that is required to reduce weight without compromising on durability.

The longevity of Hardox steel effectively reduces downtime and the cost of replacement, which is invaluable where operational efficiency is critical. Additionally, waterjet and laser cutting beds can deliver high precision with little post-processing. This significantly cuts down the need for expensive machining or welding preparation, which is particularly useful in large-scale fabrication where material integrity is key.

Defence Armour and Protection

The defence sector procures and relies on materials that can provide the utmost protection, without the additional bulk. Individuals within the defence sector favour Hardox steel due to its reliability in different environments, from extreme heat to sub-zero temperatures. Combined with its exceptional strength-to-weight ratio, it provides defence sectors with:

- Vehicle armour

- Protective barriers

- Bunkers

- Ballistic panels (resist blast effects, shrapnel, and threats)

Laser bevel cutting particularly shines when profiling armour and wear plates, processing and shaping geometries or weld-ready edges with ease and precision. This allows for laser beams to produce vehicle hulls, door panels, and modular armour kits without difficulty.

Infrastructure and Security

Hardox steel is also incredibly valued within infrastructure applications. It is often used for purposes where maintaining security and high resistance is the top priority, with key applications including:

- Security perimeters

- Fortified watchtowers

- Safe rooms

- Training facilities against ballistics

- Ballistic testing

The wear resistance of Hardox steel displays incredible durability and minimal replacement, even after undergoing frequent impact. This makes it incredibly important in defence and civilian security sectors, offering exceptional performance that’s cost-effective. The use of waterjet and bevel cutting services allows for components to achieve precise edges and pre-angled profiles, reducing fabrication time and the need for additional edge preparation.

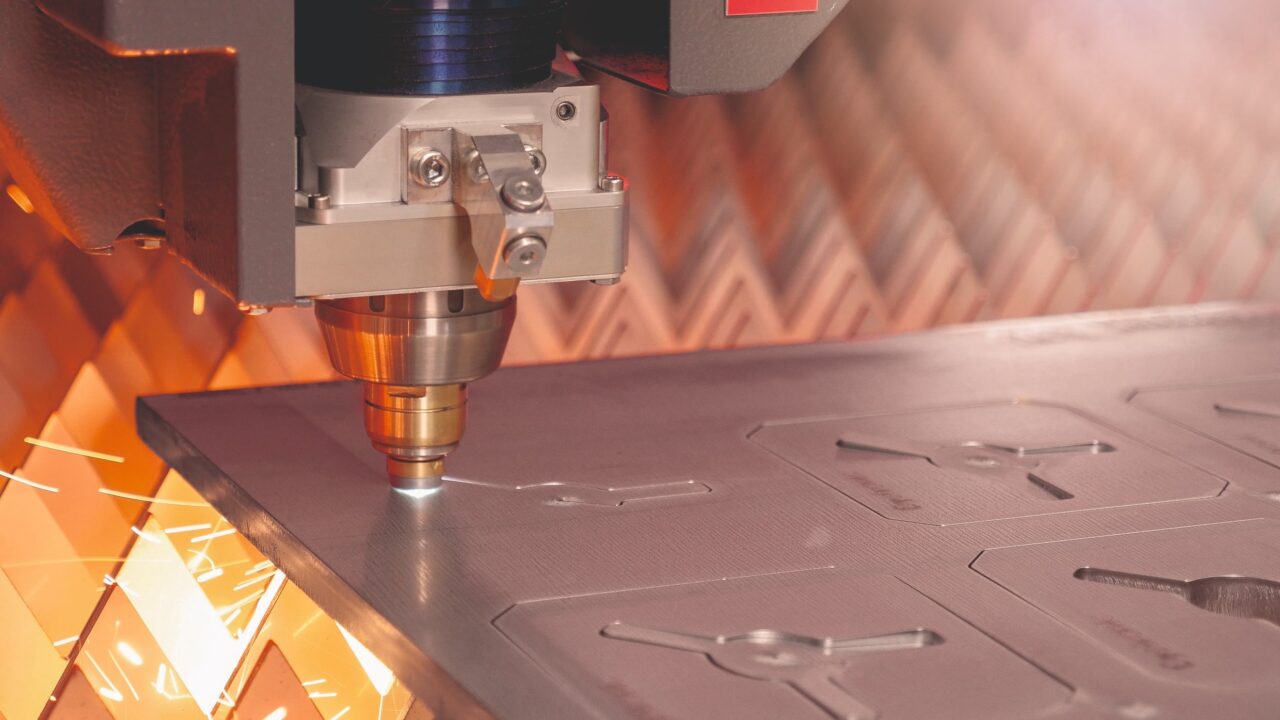

Achieving Precision with Laser Cutting

In manual fabrication, the hardness of Hardox steel makes it a challenging material to manipulate. However, the development of laser cutting allows for high accuracy, rapid speed, and clean burr free edges that are essential within defence and industrial projects. Laser bevel technology takes this further, delivering cut parts with precisely angled edges, ideal for pre-weld assemblies and structures.

Advanced laser systems are also exceptional at cutting intricate geometries with minimal waste, reliable consistency, and to a fine precision. This level of standard is paramount in the defence sector, with the need for components to slot together and perform seamlessly. Waterjet cutting is equally critical, especially on thicker or high-grade wear plates, offering cold-cutting methods that avoid heat distortion and preserve material properties.

Sustainability and Lifecycle

Sustainability and ethical practices across various sectors are becoming more standardised in the modern era. Where pressure is rising to conform to impending legislation, Hardox steel stands out. Often remarked for its long lifespan compared to traditional steel, the need for replacement and the over-consumption of raw materials are significantly lower. When combined with advanced laser cutting processes such as waterjet and laser bevel, businesses can reduce waste, energy use, and overall expenses.

Discover Exceptional Laser Cutting with Charles Day Steels

At Charles Day Steels, we are proud of our advanced fleet of lasers that can process armour and wear plate steel with effortless speed and efficiency.

We facilitate a broad range of laser cutting and additional services, from bending and pressing, bevels and countersinks, and engraving, assisting heavy-duty sectors with fabrication needs within fine margins.

If you’re looking for metal profiling that maintains structural integrity and exceptional finishes, then speak to a member of our team today for a no-obligation quote.