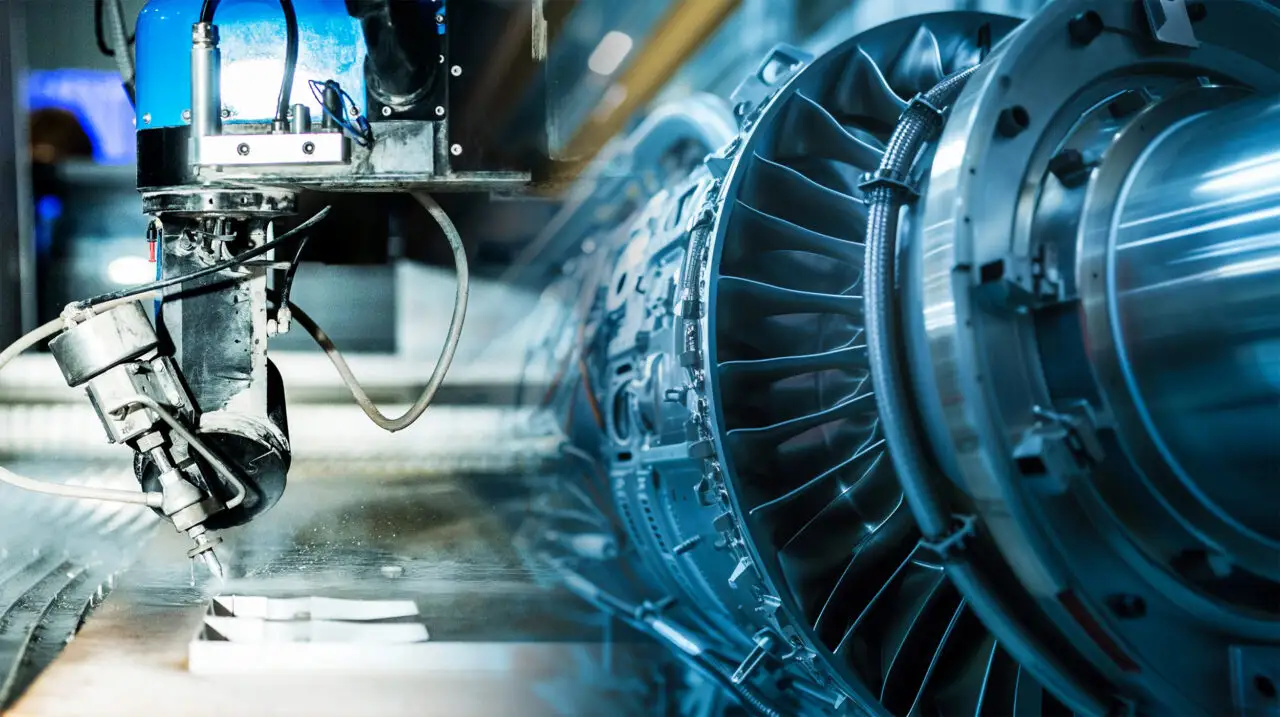

Due to increasing customer demand, we are now offering around the clock waterjet cutting.

Previously running on two shifts, the changes will see our large waterjet machines move to 24 hour cutting. The move represents our on-going commitment to providing competitive profiles, short lead times and reliable on-time deliveries.

Alan Tranter, our Waterjet Sales Manager, said

“We’ve seen a continued growth in demand for our waterjet cutting services and to keep up with this growing volume of orders we have moved to increase the number of cutting hours available.”

Ever since the installation of our very first waterjet machine back in 2006 (the largest sub-con waterjet cutting bed in the UK at the time!) and a second waterjet machine in 2007 we have been operating two shifts but this is the first time we have moved to 24 hour waterjet cutting.

We have previous experience of around the clock operation is nothing new to us, back in 2012 we moved to “lights-out” production when we installed two 2 CNC laser machines with an automated loading tower.

To coincide with the extended operating hours, we have also seen the installation of a brand new 100 horse power pump to boost the power in our two exisiting machines.

“The installation of the new pump has increased our capacity by 50%, meaning we’re able to have more heads cutting at full power at the same time, ultimately enabling us to increase our cutting speeds on a whole range of materials and thicknesses, especially thinner materials.”

Alan continued to explain how this change can benefit and suppliment our exsisting cutting operations.

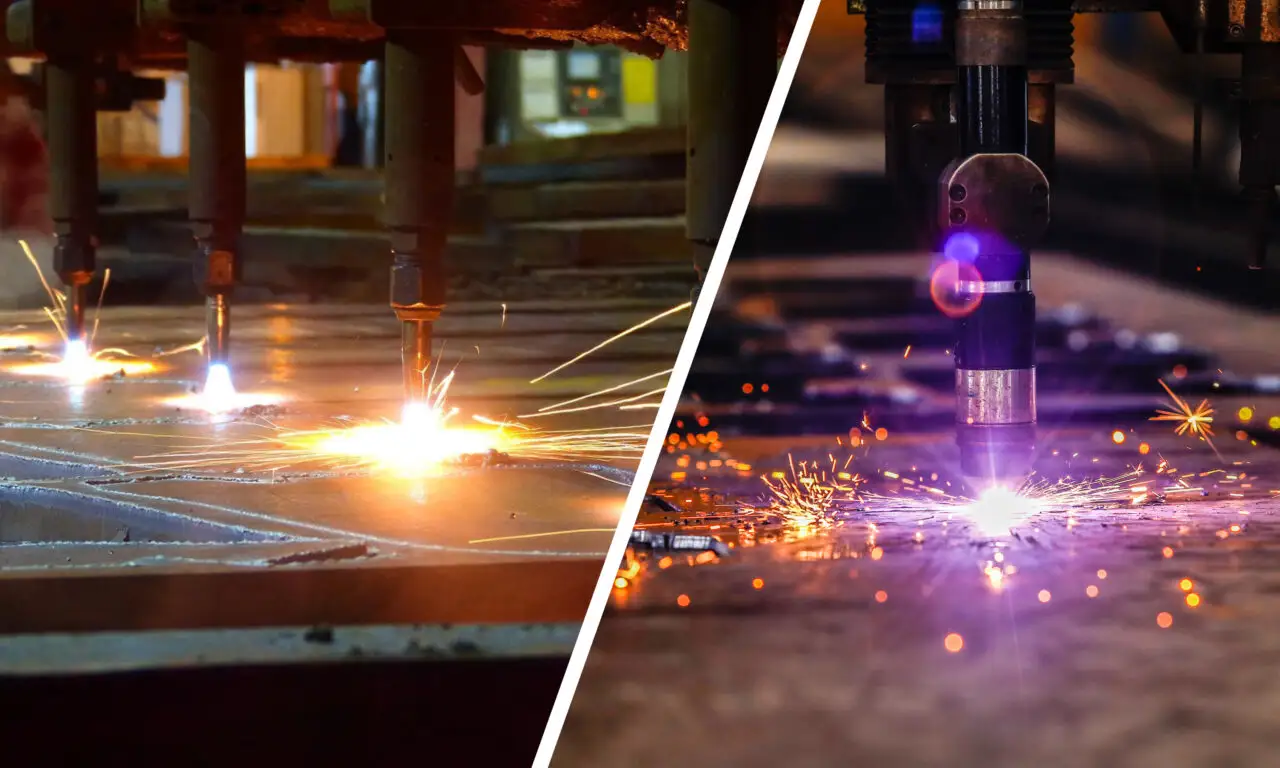

€œThe general belief within the manufacturing industry is that waterjet cutting is expensive on thicknesses below 20mm compared to other methods, namely flame and laser. The new power provided by the pump means we’re able to increase speeds on cutting 10mm thicknesses and above, making waterjet profiling more competitive €.

Waterjet cutting provides a heat-free alternative to profiling materials and as such has helped us expand into markets previously inaccessible with our laser, flame and plasma cutting technologies. The lack of a Heat Affected Zone (HAZ) and the ability to profile materials such as rubber, foam and granite has enabled Charles Day to supply parts to the creative, petrochemical and agricultural industries.

In addition to the new pump and cutting hours, further investment is planned in 2015 for our waterjet cutting divison.

Watch this space.