Professional Bronze Cutting Services

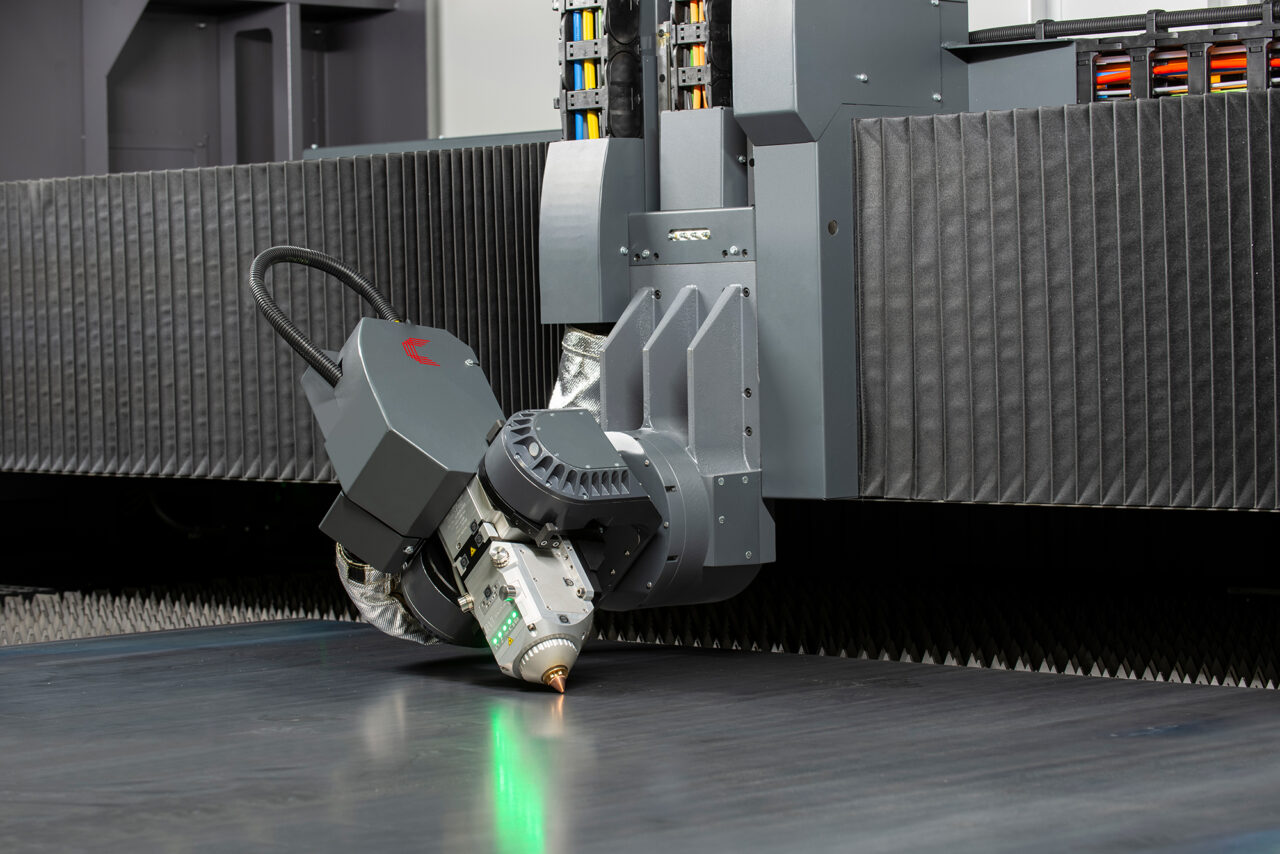

In metal fabrication, bronze is a critical material for several industrial applications, known for its diverse capabilities. Traditionally, CO₂ lasers have been known to face challenges when cutting ‘yellow metals’ due to their reflective properties. In modern manufacturing, Charles Day Steels aims to tackle this by investing in innovative fibre laser solutions that offer quality, clean-cut results.

As part of our commitment to quality, our fleet of cutting-edge machines guarantees highly refined precision, intricate design capability, eliminating reflective issues while maintaining material integrity. These lasers ensure minimal distortion and consistent accuracy, processing sheet sizes up to 6m x 2.5m across complex and high-volume projects.

With the ability to cut up to 20mm thick, laser cutting is particularly advantageous for industries requiring quality metalwork, such as electronics, aerospace, and decorative parts. Despite bronze being categorised as a challenging metal to work with, we are confident in our skilled laser cutting techniques, accompanied by waterjet cutting for thicker sheets; we embrace the challenges.

Typical Bronze Cutting Applications

Bronze is valued for its strength and resistance to corrosion and wear. Typical applications include:

- Bearings and bushings

- Pump and valve components

- Marine hardware

- Sculptures and art pieces

- Architectural elements

THE ALL-IN-ONE

Boost Efficiency with Laser Bevel Cutting!

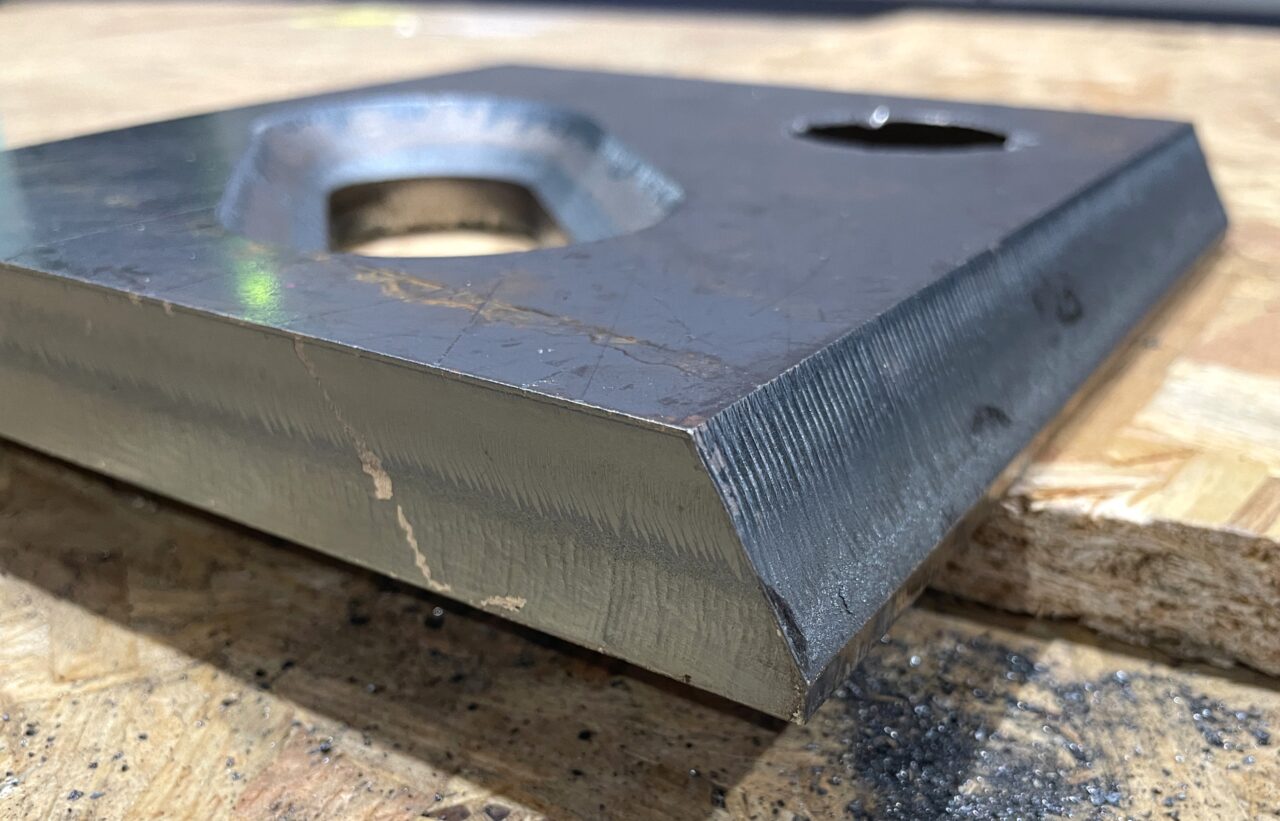

Save time and reduce costs with our advanced 50-degree Laser Bevel Cutting. Get fabrication-ready parts with built-in weld preps, eliminating manual grinding and speeding up assembly. Stronger joints, faster turnaround, lower costs.

Why Trust Charles Day Steels for Bronze Cutting?

As one of the UK’s leading metal profiling companies, we strive to revolutionise the metal profiling and fabrication industry, paving the way for sustainable laser cutting services. With over four decades of expertise, part of our philosophy focuses on continuously re-investing back into the business with the latest technology and renewable energy sources.

We offer a comprehensive range of in-house metal profiling services, committed to delivering diverse cutting, 24-hour production, competitive pricing and providing stringent quality assurance. We strive to ensure maximum efficiency, streamlined processes and economical profiling for the value of our clients.

Bronze Laser Cutting Capabilities

Maximum Cutting Size

6m x 2.5m (6000mm x 2500mm) and beyond 10mm for waterjet cutting

Maximum Material Thickness

20mm

Minimum Material Thickness

0.1mm

Complex Details

Our CNC driven laser cutting machines can process even the most complex and intricate designs. We can laser cut perforations to your specifications and cut flat, pre-perforated bronze sheets to any drawing provided.

Cutting Tolerances

View our laser cutting tolerances here.

Cutting Edge Quality

To prevent oxidisation and ensure a clean, blemish-free cut with no discolouration, we shroud the laser in nitrogen gases, so they’re ready for welding without any extra machining. Bronze can be laser cut up to 5mm and maintain a smooth cut edge.

Bronze Cutting Grades

We can laser cut a range of bronze grades and alloys. The most commonly asked for:

- PB103

If the grade you require is not on this list, we should still be able to source and cut it. Please contact us with your exact grade requirements.

Sheet Metal Laser Cutting Thicknesses

With a plethora of in-house laser cutting capabilities, we can laser cut sheet metal in a variety of thicknesses depending on the material selected.

Laser Cut Thickness (mm)

Benefits of Bronze Cutting by Charles Day Steels

Precision Cutting

Our state-of-the-art fibre laser technology ensures precise cuts with minimal distortion, resulting in a high calibre of finish that meets the relevant requirements of several industries. Our machines ensure flawless execution and detailed designs.

Versatility

We’re capable of handling a broad range of applications with our laser cutting processes, cutting parts for electrical components to decorative hardware, with the scope to handle varying thicknesses and grades of bronze. We endeavour to provide adaptable and dynamic services to your requirements.

Clean Cut Edges

Laser cutting is remarkable at producing smooth edges, clean cuts and mitigating burrs or rough edges left from mechanical cutting methods. This significantly reduced the need for second finishings, which cuts labour expenses, post-processing times, and ready-to-use assembly parts.

No Surface Contact

Due to the non-contact process of laser cutting, the surface of the material is not at risk of damage or contamination. This is especially beneficial for bronze, resulting in clean and unmarred surfaces for structural and aesthetic applications.

Complex Shapes

Our laser cutting machines aid the fabrication of fragile, intricate, and complex designs with high precision. This is beneficial for industries that require bespoke components, particularly for automotive, electrical and decorative parts. Due to its high volume capability, laser cutting can be set apart from traditional cutting methods.

Cost Effectiveness

Cutting-edge and innovative laser cutting machines offer cost-effective advantages over traditional methods such as milling and punching. Automation capabilities increase the ability for mass production without compromising quality, establish rapid lead times and eliminate material waste.

In-House Bending & Pressing

Charles Day Steels accompanies its bronze cutting services by providing in-house bending and pressing services for ductile materials. Our remarkable project lead times and 24/7 production ensure that your project’s assembly processes are efficient and meet a high standard of quality.

We process a broad spectrum of materials, including copper, brass, bronze, mild steel, stainless steel, aluminium, and more. For additional information about bending and pressing solutions, get in touch with a member of our team today.