High-Grade Laser Cutting for the Medical Industry

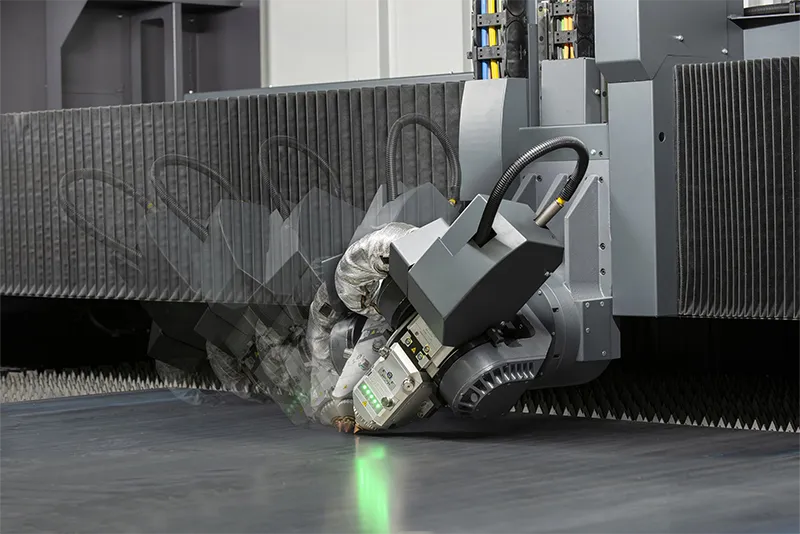

Medical device manufacturing stems from an industry that relies heavily on stringent quality control, precision, and intricacy. As the medical field continues to innovate, so does the need for laser cutting and manufacturing processes to produce devices that offer transformative, consistent results while remaining fully traceable.

At Charles Day Steels, we are adept at understanding what the medical sector expects from laser cutting and the manufacturing of tools and devices. Achieving consistent and high-quality results is what we excel at, with the ability to process complex and intricate designs without hindering structural integrity and performance.

We process materials such as stainless steel, titanium, copper, polymers, and carbon fibre, which are crucial in developing robust medical components. As leaders within the profiling industry, we take the time to understand the properties of each material, ensuring to apply the most suitable non-contact method that retains the highest level of quality. Whether it’s surgical instruments or a medical implant, we exceed outcomes and embrace projects that are labelled as complex.

How Charles Day Steels Stands Out in Medical Profiling

As a leading brand across the laser cutting and profiling sector, we combine advanced lasers and client requirements to deliver exceptional results. Our streamlined solutions offer end-to-end services along the entire production journey, adhering to our ongoing commitment to sustainable fabrication and continuous reinvestment.

We always strive to deliver more, offering a range of in-house solutions for the medical industry. Our comprehensive solutions stem from initial prototyping and etching to smart design production, and more. At Charles Day Steels, we always listen to our clients, offering competitive pricing, remarkable quality control, and the ability to process complex geometries.

Advantages of Laser Cutting in Medical Manufacturing

Laser cutting delivers comprehensive advantages in the medical industry; some key benefits include:

Fine Precision

Laser cutting can achieve exceptional finishes, cutting a variety of materials within tight tolerances. Our lasers can even process detailed and refined cuts on small, intricate designs, without compromising quality.

Material Versatility

Various laser cutting and profiling processes can cut a range of biocompatible materials with ease, including titanium, stainless steel, and polymers. Whether it’s surgical instruments, stents, diagnostic devices or implants, we can deliver.

Complex Designs

With the integration of smart design production, our in-house team can take complex projects and deliver seamless solutions. From nesting to 2D and 3D geometries, medical devices can be executed flawlessly.

Sterile Processes

Our laser cutting procedures follow a non-contact process, protecting the material from damage and the possibility of contamination.

Stringent Compliance

The sterile and consistent performance of laser cutters ensures that manufacturers can meet strict regulatory compliance within the medical sector.

Reduced Waste

We minimise waste by optimising projects to the highest level of standard, with CAD nesting procedures that ensure materials are used as efficiently as possible, retaining value and optimising overall production.

Laser Cut Applications in Medical Manufacturing

Applications of laser cutting in the medical industry include, but are not limited to:

Surgical Instruments

Forceps, scalpels, bone-cutting tools, and scissors.

Stents and Catheters

Lattice designs and micro-textured polymer tubes.

Implants

Joint replacements, dental and other orthopaedic implants.

Heart Valves

Biocompatible components for aortic, mitral, and tricuspid valves.

Diagnostic Equipment

Parts for pacemakers, blood glucose monitors, X-ray, and MRI machines.

Robotics

Components within advanced robotic surgery equipment.

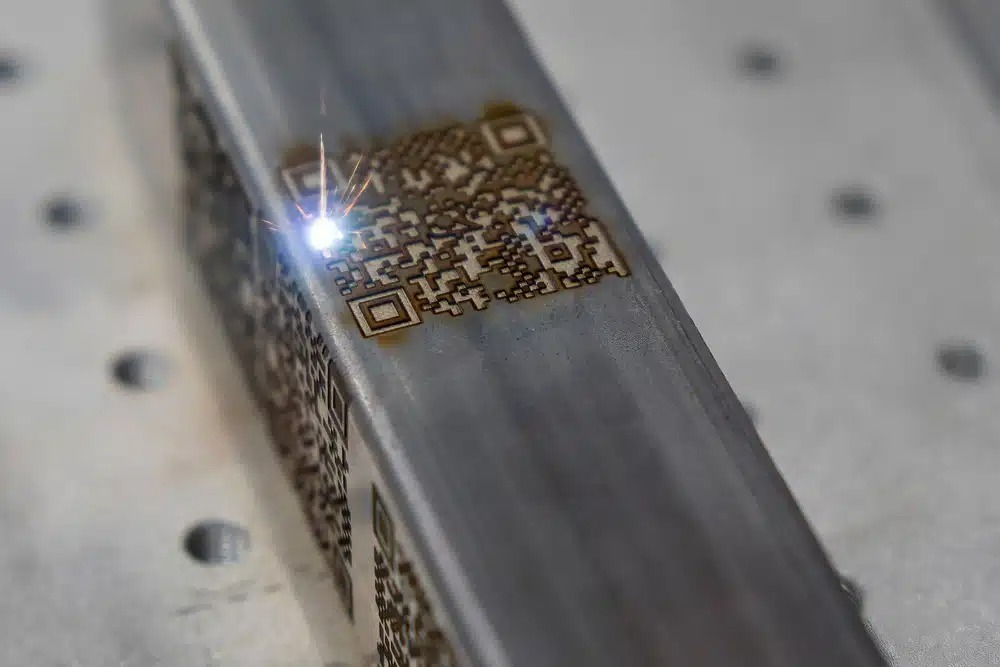

Traceability

DataMatrix codes, serial numbers, and batch codes.

Laser Etching and Engraving

Under legislation, medical equipment is required to remain fully traceable to prevent rapid recalls and counterfeit products, ensuring that public safety and well-being are of the highest priority. Laser etching and engraving create permanent, high-resolution serial codes, logos, and critical identifier information.

At Charles Day Steels, we deliver powerful laser etching and engraving to facilitate modern manufacturing and medical sector requirements. With the versatility to be applied across various biocompatible materials, laser etching and engraving technology is invaluable when aiming to maintain full traceability and industry compliance.