Exceptional Laser Cutting in Electronics Manufacturing

The electronics manufacturing sector continues to thrive, increasing the demand for more handheld and compact devices. With the growth of innovative technology, including electric vehicles (EVs), there is increasing demand for critical components requiring intricate laser cutting processes, ensuring the longevity and quality of a product.

At Charles Day Steels, we deliver rapid results that cater to the unique requirements of the electronics industry. Achieving a high-grade execution relies on consistent accuracy within incredibly tight tolerances. Our flat-bed lasers are adept at processing a range of components, brackets, and casings within electronic manufacturing.

We process materials such as brass, copper, aluminium and Zintec, all necessary metals within electronics. As market leaders, we utilise advanced lasers that are equipped to handle the unique properties of each metal, ensuring each one is tailored and cut efficiently to achieve the highest level of quality. Backed by expertise, we navigate complex challenges with ease, whether it’s detailed designs or unique requirements, Charles Day Steels offers reliable outcomes.

Waterjet Cutting

Waterjet cutting is a vital cutting process for copper components such as busbars, which require precise, clean edges without heat distortion, maintaining conductivity for EV and electronics applications.

This is particularly useful when cutting busbars, which are long, narrow parts that often undergo bending and pressing. Unlike laser beam, waterjet is a cold cutting method that maintains copper’s conductivity and integrity, making it a preferred choice in electronics.

At Charles Day Steels, we use the latest waterjet technology to achieve exceptional finishes within tight tolerances on copper, ensuring reliable performance within demanding sectors such as electric vehicles and telecommunications manufacturing.

How Charles Day Steels Excels in Electronic Fabrication

As one of the UK’s leading profiling companies within the market, we effortlessly combine quality and expertise to deliver cutting-edge results. Our ethos for high-quality results is exemplified by our commitment to sustainable solutions and reinvestment back into our technology.

We’re proud to supply an extensive range of in-house laser fabrication solutions for the electronics industry. Our turnkey approach encompasses laser cutting, waterjet cutting, flame cutting, bending and pressing, bevel cutting, and more. We always strive to go beyond, offering competitive pricing, remarkable quality control, and the ability to process complex geometries.

Advantages of Laser Cutting in Electronic Manufacturing

Laser cutting delivers comprehensive advantages in the electronics industry; some key benefits include:

Unmatched Precision

Laser cutting can process complex geometries and intricate details that are vital for compact and delicate electronic components. Our laser achieves incredibly refined and clean cuts within fine tolerances, even on reflective materials.

Consistent Performance

Our advanced lasers guarantee uniformity even across high production volumes, particularly through the use of our CAD machines and designs. Our clientele can be confident knowing they can depend on reliable and consistent results.

Rapid Turnaround

We offer services from prototyping to mass production within quick lead times. We can enable fast-paced procurement and production through powerful lasers without compromising on quality.

Minimal Material Waste

We reduce waste by ensuring high-quality execution of projects and through our CAD nesting procedures that ensure materials are used as efficiently as possible. This effectively retains valuable material and optimises overall production expenses.

Versatile Capabilities

Whether producing intricate micro-scale parts, robust casings, or heat-dissipation designs, laser cutting can cut across 2D and 3D designs, while minimising heat-distortion and the need for additional processing.

Laser Cut Applications in Electronic Manufacturing

Applications of laser cutting in the electronics industry include, but are not limited to:

Precision Components

Connectors, switches, brackets, terminals, and internal fittings.

Protective Casings & Housings

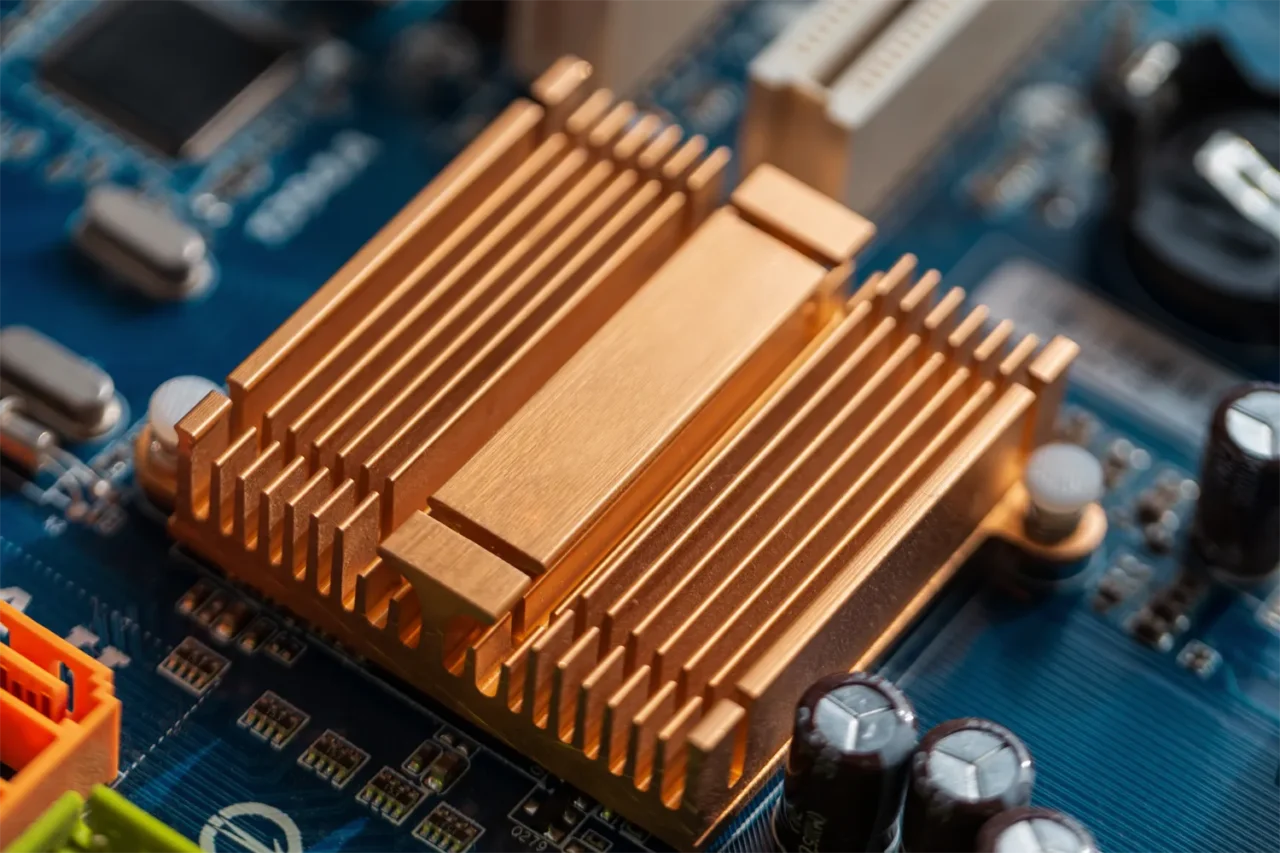

Enclosures, shields, and heat sinks of varying geometries.

Circuitry & Conductive Parts

Accurate cutting of copper, brass, and aluminium for conductivity.

Prototyping & R&D

Rapid production of test parts and prototypes with reduced lead times.

Laser Marking & Traceability

Barcodes, serial numbers, batch codes, and QR codes for product tracking and compliance.

Thermal Management Solutions

Cutting and shaping components that improve cooling efficiency in compact electronic devices.

Battery Components

Cell and tab connections, power electronic substrates, busbars and motor laminations.

Electric Vehicle Components

Precision laser and waterjet cutting for battery housings, power electronics, and other EV parts.