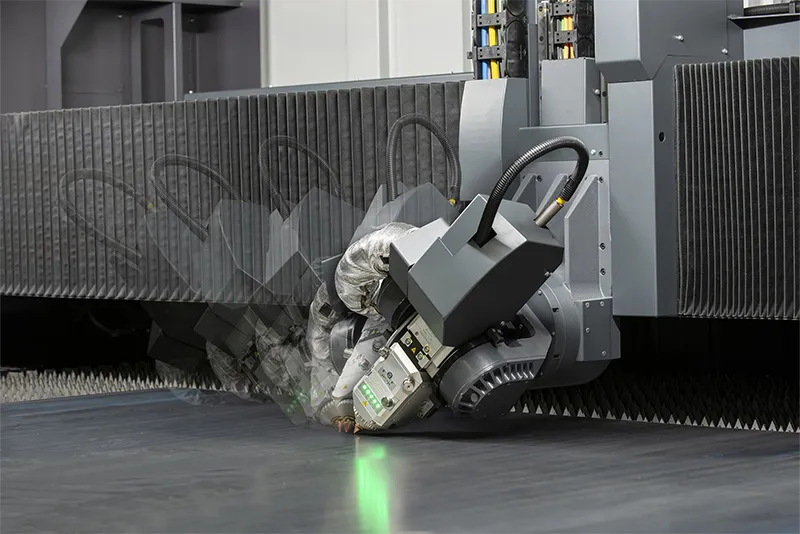

Laser Cutting in the Automotive Industry

The automotive industry relies on high precision, facilitating complex supply chains, rapid lead times and achieving exceptional quality within stringent trade standards on an international scale. Due to the level of calibre required, tolerances must remain tight with low-margin errors.

As part of our ethos, Charles Day Steels commits to providing the latest cutting-edge technology to maintain our high level of quality and adhere to automotive standards. Our laser-cutting beds process a wide range of materials including, mild steel, stainless steel, aluminium, and titanium. Our large fleet of flat-bed lasers can accommodate sheet sizes up to 6m x 2.5m to process complex, intricate and large-scale projects across all metal types.

As a market leader in fabrication, we place quality assurance at the forefront of our operations, ensuring each project meets its intended purpose. We understand that different metal types come with their own challenges, which is why we deploy a wide range of techniques to handle properties such as reflective or heat-sensitive metals with ease.

Why Trust Charles Day Steels with Laser Cutting

As one of the UK’s leading metal profiling companies, we have always committed to re-investment, offering only the latest technology on the market for all our clientele. With a strong foundation in sustainable manufacturing, our processes aim to drive down expenses, increase turnaround times, and revolutionise industry practices.

We offer a comprehensive range of in-house metal profiling services, from CAD design prototyping, bending and pressing, weld prep parts and secondary finishes. With over four decades of experience, we always exceed project expectations; delivering 24-hour production, competitive pricing and stringent quality assurance.

Advantages of Laser Cutting in Automotive Sectors

Laser cutting offers a diverse array of benefits, from processing complex shapes to reduced material waste, laser cutting is indispensable in the automotive sector. Some of the key advantages include:

High Precision

Laser cutting enables exceptional precision cuts with minimal distortion, resulting in incredibly high-quality finished parts without the need for additional processing such as deburring.

Exceptional Speed

Laser cutters can handle high throughput with ease, providing rapid and highly accurate results across scalable projects. Their reliability facilitates cut components that enhance downstream processes.

Reduced Waste

Through smart CAD design and innovative technology, laser cutting can reduce waste by optimising patterns and effectively driving down expenses. This not only saves on material costs but is sustainable too.

Dynamic Solutions

Advanced laser cutting techniques can effectively cut complex and intricate parts across 2D and 3D designs. This is incredibly valuable for projects that require custom components.

Cost-Effective

Due to the high efficiency of laser cutters, they substantially reduce material waste, energy consumption and lead times. Collectively, laser cutting drives down the cost of initial expense and maximises profit.

Material Capacity

Laser cutting can profile a wide range of materials, from high tensile strengths to challenging reflective metals. If we don’t stock the material you require, it can be procured in as little as 24 hours.

Laser Cut Applications for Automotive Industries

Some applications of laser cutting in the automotive industry include, but are not limited to:

Exterior Body Panels

(Doors, hoods, bumpers and all panelling)

Engine Components

(Gears, bearings and shafts)

Airbags

Chassis

Electronics

Plastic Parts

(Interior panelling, license plates and trims)

Textiles

(Seat belts and upholstery)