Robust and Reliable Laser Cut Parts for the Agriculture Industry

Essential industries for the public, such as agriculture, require resourceful and cost-effective solutions. Particularly when there is pressure for more inventory, greater manpower, and investment in sustainable practices when approaching work.

For agricultural sectors, the need for custom, hard-wearing and reliable structural components is non-negotiable, with little room for error and part failure. At Charles Day Steels, we offer exceptional laser cutting and fabrication solutions that withstand all applications, irrespective of harsh weather conditions or wear over long periods of time.

We utilise our expansive fleet of advanced laser cutting beds, cutting to complex designs and geometries with minimal material waste and a reduced need for secondary procedures. Additionally, we can procure a vast range of materials, typically within a 24-hour turnaround, allowing us to expedite lead times regardless of the thickness and hardness rating of any material.

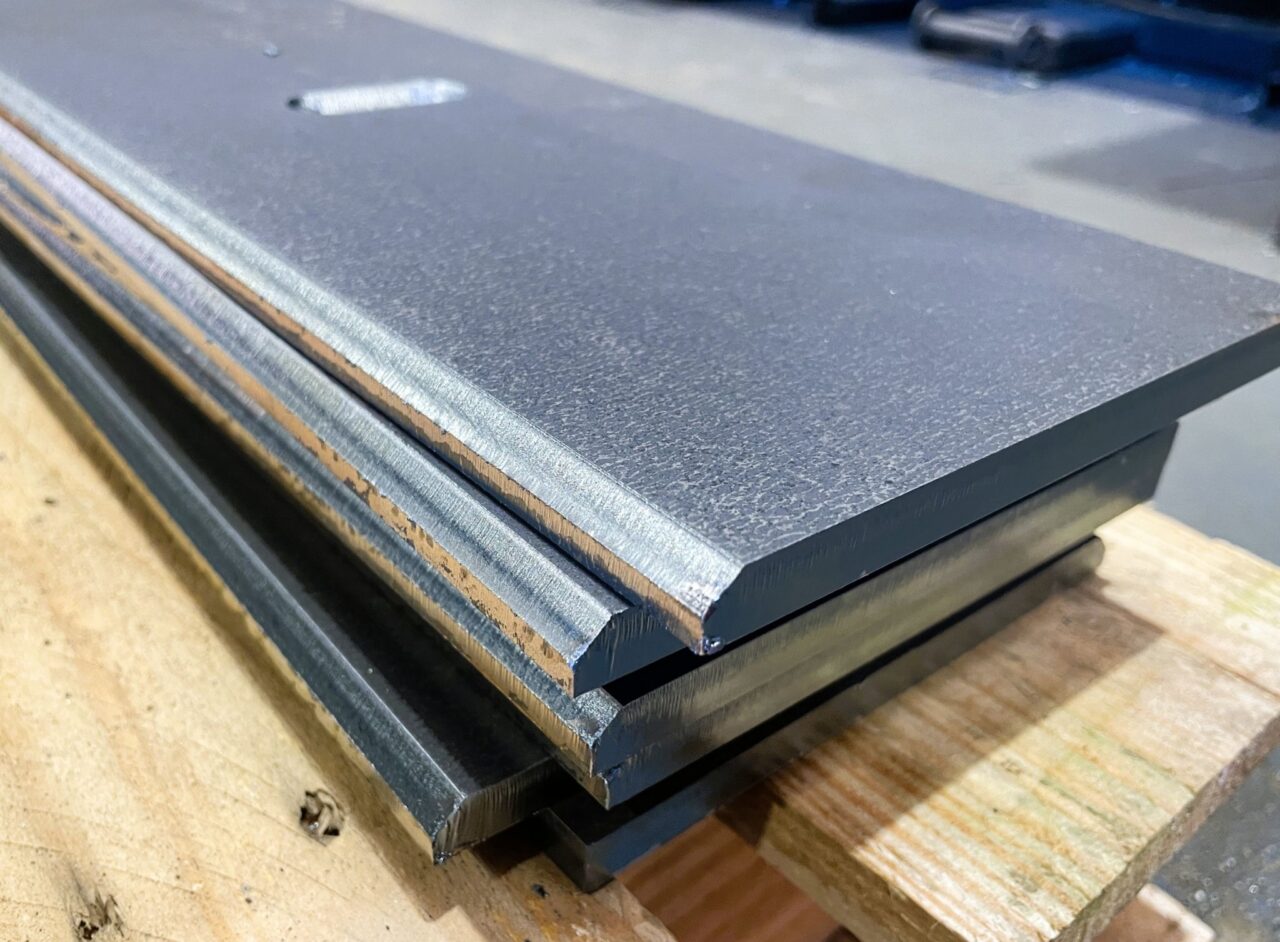

Wear Plate and Laser Bevelling for the Agricultural Industry

Wear plates, such as Hardox, are incredibly durable and resistant to abrasion, which is particularly beneficial in harsh weather conditions, high-impact uses, and general protection from wear and tear. In agricultural sectors, this can encompass plough blades to bucket liners, which rely on high-friction processes, yet are not subject to poor performance and loss of longevity. At Charles Day Steels, we profile hard-wearing metals, such as wear plates, to an exceptional finish and offer bevels with clean and accurate edges.

- Exceptional resistance to heavy wear and impact

- Applicable for heavy-duty components, such as blades, liners, and cultivation

- Retains structural integrity, even when cutting high-tensile materials

- Ability to offer accurate 45° bevels and weld preps

- Reduced need for grinding or secondary finishing

- Flawless edge quality for seamless fits and high-grade parts

How Charles Day Steels Elevates Agricultural Industries

With decades of experience behind us, we are confident in our knowledge across a multitude of sectors, with agriculture as no exception. Our turnkey approach in laser cutting allows us to expedite materials, prototype designs, pressing, and countersinking, even across large-scale production, guaranteed to be highly accurate, burr-free and refined.

As a leader in the metal fabrication market, we are committed to quality and the outcome. Fully certified to ISO 9001 and BS EN 1090-1, we meet stringent UK and EU legislative guidelines, and consistently reinvest and commit to sustainable manufacturing. Our fleet of lasers and additional services are designed to offer short lead times at competitive pricing, bespoke designs and reduce the need for secondary processing, all under one roof.

Advantages of Laser Cutting in Agricultural Manufacturing

Laser cutting encompasses a range of advantages in the agricultural industry; key benefits include:

Exceptional Precision

Parts and components can be produced within remarkably tight tolerances, allowing for a seamless fit, even if deemed as an intricate or complex part. Laser cutting is renowned for producing clean, burr-free cuts, even on 45° bevels and contours

Versatile Design

Laser cutting is excellent at simplifying the complexity of prototyping, custom design requirements, and the types of materials used. Regardless of thickness or geometry, smart design production can process one-off or scaled projects with ease.

Expedited Lead Times

From material procurement through to the production phase, advanced cutting techniques, such as open section laser cutting, can offer a projected 50% reduction in lead times.

Complex Geometries

No project is too intricate or complex when used alongside our smart design production. We have the capacity to handle 6-axis geometries, with flawless execution, all within consistent, automated production.

Sustainable Manufacturing

Introducing smart nesting techniques helps to significantly reduce material waste, effectively saving costs. Such processes help to create a more energy-efficient and streamlined approach to laser cutting.

Structural Integrity

An in-depth understanding of varying material properties and characteristics allows our expert team to choose the right service for your project. We can cut parts through non-contact processes and reduce heat to avoid distortion and warping.

Laser Cut Applications in the Agriculture Industry

Applications of laser cutting in the agricultural sector include, but are not limited to:

Machinery Components

Harvester parts, plough blades, seed drill components, tractor frame assemblies.

Structural Elements

Barn supports, fencing, housing, storage frameworks.

Precision Parts

Irrigation fittings, brackets, mounting plates, gears, and self-jigging components.

Traceability

DataMatrix codes, serial numbers, batch codes.

Bespoke Solutions

Gates, feeders, protective guards, custom designs.

Common materials we cut in the agricultural sector:

- Stainless Steel

- Mild Steel / Steel Plate

- Hardox Steel

- Aluminium

- Brass and Copper

- Acrylics

- Wood