1. Customer Enquiry

A customer contacts us with a requirement for a cut profile which is to go on and be used within the construction industry.

2. Customer Request

At enquiry stage the customer specifies to us that the part requires CE Marking.

3. Cutting Procedures

Using CE Marked sheet/plate, profile is processed following strict guidelines set out within our Factory Production Control system.

4. Collection / Delivery

Upon completion, the finished profiles are BS EN 1090-1 compliant suitable for use in EXC 1 – EXC 4 classes. The profiles are then ready for delivery or collection.

Certification to BS EN ISO 9001:2015

The company has also achieved separate TUV Certification to BS EN ISO 9001:2015. This serves to assure our clients of a fully qualified team of experienced personnel as part of all activities from receiving the enquiry through to delivery. The Comprehensive quality standard covers the Manufacture of Ferrous andNon-Ferrous Profiles and Parts of engineered products and specialist equipment. This includes safety critical items using Carbon, Stainless and Aluminium.

Certification to BS EN ISO 14001:2015

Our green-centric focus and strive towards sustainable integrations within business operations have resulted in Charles Day Steels obtaining ISO 14001 accreditation. The Environmental Management Systems (EMS) framework rewards businesses for their ongoing commitment to environmental improvements and understanding of sustainable policies. We’re apart of just 500,000 businesses worldwide that hold such a highly recognised accolade.

TUV NL Certification to BS EN 1090-1:2009+A1:2011 Execution class 4

To work in the most safety critical environments requires the highest levels of quality assurance We have been awarded a Factory Production Control (FPC) certificate conforming tothe BS EN 1090-1:2009-+A1:2011 standard. The Company Certification is to Execution class 4 which is the highest achievable level. This demonstrates that the Company is able to provide advanced level compliance to the CE marking required in Structural Steel Regulation, and competent to work onthe most demanding, zero tolerance projects.

We join an elite group of UK companies in achieving this prestigious standard – Execution Class 4 should be applied to special structures or structures with extreme consequences of a structural failure asrequired by Design Authority.

What materials can be cut in compliance with BS EN 1090-1?

Our certification allows us to profile and cut the following metals:S235, S275, S355, Stainless Steel 304, Stainless Steel 316 and Aluminium.

Forward Thinking as Standard – BrexitReady

As the UK Market changes ready for Brexit be assured that Charles Day have made provisions including our Certification for BS EN 1090 with TUV NL to ensureCDS can continue to offer the Conformité Européenne CE Mark even in the scenario of a No-Deal Brexit where we will also utilise the UKCA Marking for our UK Market.

We look forward to the exciting challenges ahead and are happy to answer any requirements/questions you may have on this subject.

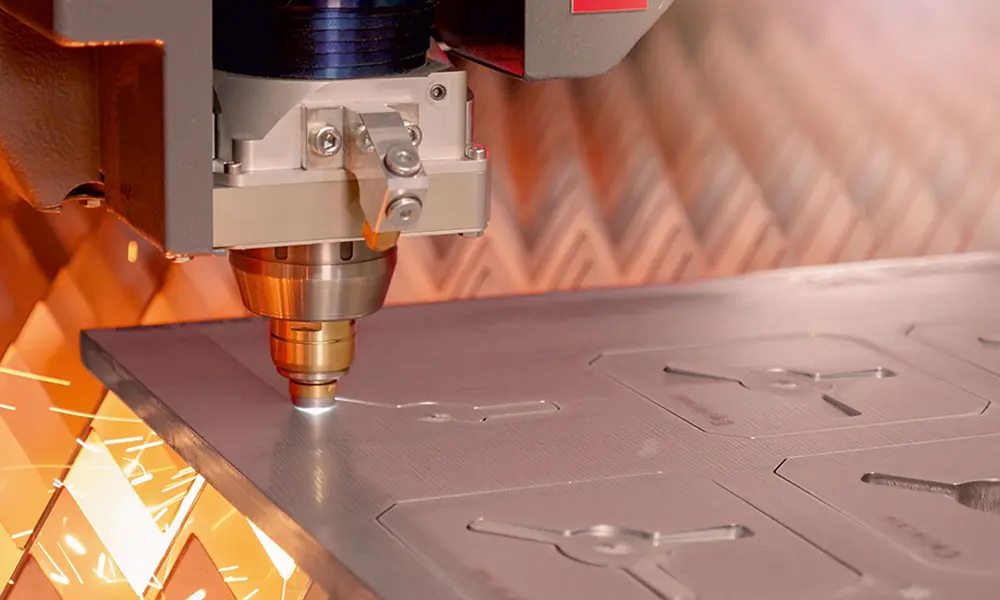

CE Ready Laser Cutting

Taking advantage of our state-of-the-art lasers which include 4 CO2 and 2 fibre CNC laser cutting machines, we’re able to offer BS EN 1090-1 compliant laser cutting services for sheet/plate up to 6m x 2.5m and 25mm thickness.

CE Ready Flame Cutting

Our traditional flame cutting methods are also suitable to provide CE ready carbon and mild steel profiles and cut parts up to 270mm thick. Multiple flame cutting heads enable short lead times on large batch runs.

WaterJet Cutting CE Marked Material

We possess one of the largest sub-contract waterjet cutting beds in the UK, able to accept 8m x 4m in thicknesses up to 230mm. We are more than happy to cut your CE Marked material or source and cut CE material for you.

CE Ready Plasma Cutting

Our BS EN 1090-1 compliant plasma cutting services for structural metalwork are suitable to cut various grades of carbon/mild steel, stainless steel and aluminium in 12m x 5m sheets in thickness of up to 30mm.

Capacity

Boasting a collection of 6 of the latest CNC fibre and C02 laser cutting machines running 24 hours a day, we can offer the shortest possible lead times at competitive prices nationwide, even for the most challenging of projects.

Quality

With our ISO9001 and BS/EN 1090-1 accreditations we are proud to deliver a quality product and service every time, providing our customers with the confidence that orders will be delivered on time and correct to the highest of standards, every time.

Experience

With over 30 years of experience in the laser profiling industry, our engineers can help make requirements a reality, offering a wealth of knowledge and expertise at every stage of your production process.

Quality Assurance

Quality. Accuracy. Compliance.

From drawing to delivery, Charles Day take pride in delivering quality profile cutting services to boost downstream efficiency and profitability.

Factory production controls comply with construction product regulation BS EN 1090 EXC4 for intricate cutting of construction and nuclear regulation profiles.

Certified to BS EN ISO 9001:2015 for all profiling requirements.