Quick Links

Manufacturing in the modern era is rooted in precision and efficiency, focused on executing designs to a high standard. The finish of edges can be a larger part of the process that many don’t realise, ensuring prepped metal components are immediately ready for welding and assembly.

Two of the most common methods to treat edges are chamfering and bevelling, each producing variable outcomes depending on the material type, such as strength, cost, and final performance. This guide helps to differentiate between each process, helping you understand the right service for your next laser cutting project.

What Is the Difference Between Chamfering and Bevelling?

Both chamfering and bevelling involve cutting an edge at an angle; however, they are also different in the way they cut and the applications they serve.

Chamfers are typically a uniform and small edge type, commonly at 45° and effective at removing 90° edges. They eliminate burrs and sharp edges, offering a safer and more functional purpose rather than structural.

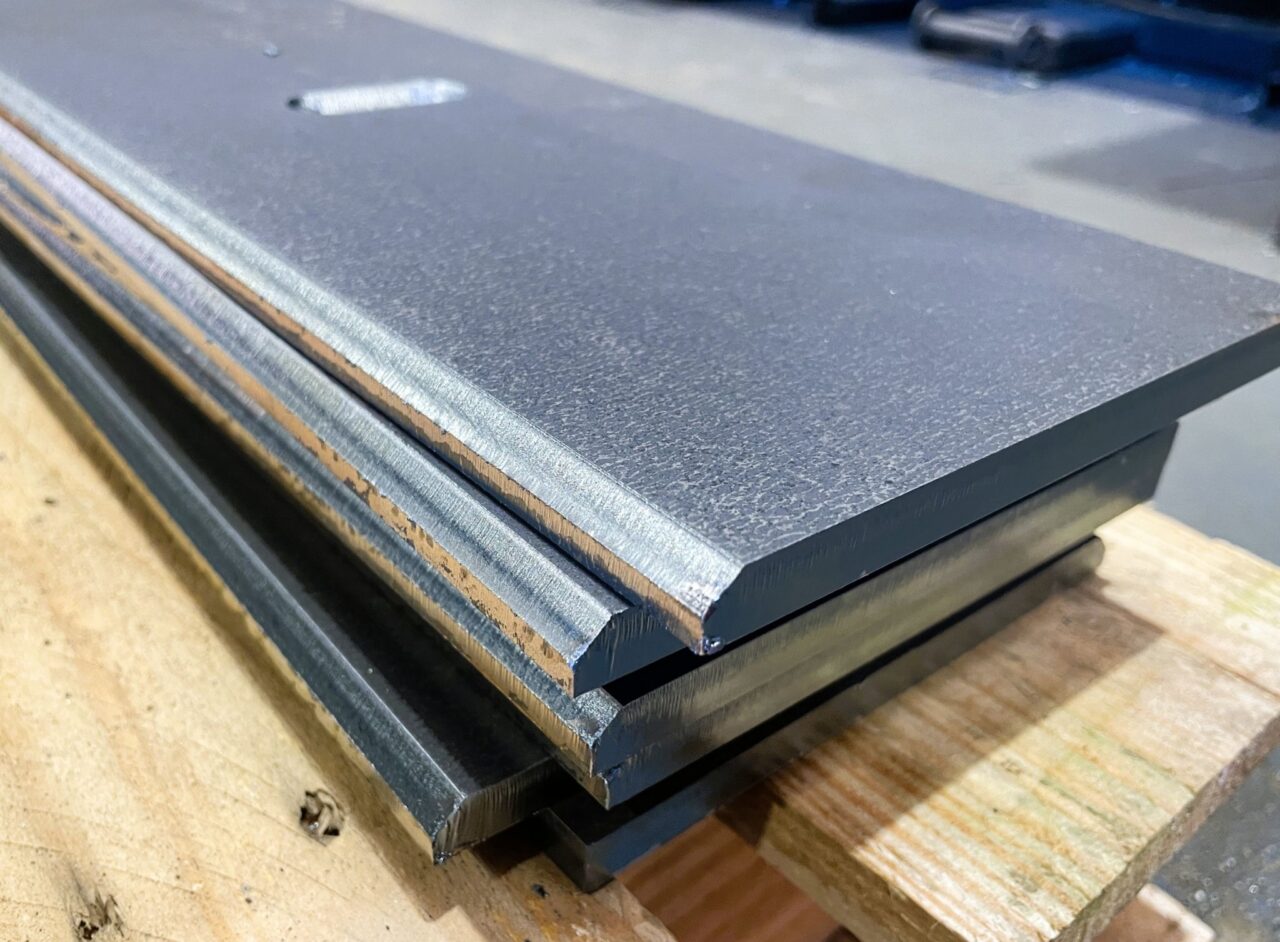

Bevels feature a sloped and larger-angled edge that is cut to the thickness of the material, commonly at 45°. Bevelling is known for producing more deliberate and deeper cuts, which is beneficial for welding joints, and where load-bearing strength is required.

When Is Chamfering Needed?

Chamfering is particularly useful where safety improvements, fastenings, and aesthetics are important. The removal of sharp edges helps to reduce the risk of injury during handling, while allowing for components to slot together more easily during assembly. Common applications include:

- Enhancing part handling and operator safety

- Smoother assembly with bolts and fasteners

- Improve visual aesthetic for exposed components

- Reduces minor edge damage during potential impacts

For many projects, chamfering can often be an economical choice, especially when structural load-bearing strength and weld-prep parts are not required. Laser cutting technology can produce consistent chamfers quickly, reducing lead times and cost.

When Is Bevelling Needed?

Bevelling is noted for its weld-prep ability and capacity to be used in heavy-duty applications. The deeper angle on edges allows for greater contact and strength when welding, improving joints and load distribution. Bevelling is commonly used for:

- Weld preparation on thick plates and pipes

- Structural steel components

- Pressure vessels and load-bearing assembly

- Projects with strict engineering or compliance requirements

While bevelling may be a longer process compared to chamfering, it provides undeniable results when it comes to weld prep quality, reduction of rework, and industry standard compliance.

How to Choose the Right Edge for Your Project?

A reputable laser cutting and profiling company will have the knowledge to guide you on the right method for your project. This mostly comes down to the expected outcome, end purpose, and the type of material being used. Some common questions may include:

Does the part need to be welded or used for load-bearing applications? If yes, then bevelling may be most optimal.

Is safe handling and clean assembly a necessity? Chamfers are usually ideal in this case.

Are tolerances, strength, and the ability to cut thick plates important factors? Bevelling would likely be the best choice.

Is cost-efficiency and faster turnaround a priority? Chamfers often offer the best value.

Why Laser Cutting Is Ideal for Chamfering and Bevelling

Modern laser cutting technology creates highly accurate and excellent quality chamfers and bevels, all produced within a singular, controlled process. This often leads to:

- Consistent angles and clean edges

- Reduced need for secondary finishes

- Faster turnaround times

- Improved repeatability during scaled production

- Variety of angles and weld prep configurations

Laser machinery also allows bevel angles to be tailored specifically to each project’s specifications, helping to offer the most optimised approach to welding and assembly.

Achieve Flawless Edges with Charles Day Steels

At Charles Day Steels, we understand that the extra details, such as edge preparation, are incredibly important to your project’s final execution. Our laser bevel and chamfer services are designed to deliver exceptional quality within rapid lead times.

We offer chamfers and bevels between 15° and 60° on various thicknesses and weld prep angles. Our team are always on hand to provide guidance throughout the process, so your project is set up for success from the start.

Get in touch with Charles Day Steels today to discuss your requirements and the value of precision laser cutting.