Steel is a part of our daily lives and is used on a global scale. It’s an integral component throughout heavy-duty sectors and the essential items we use in our homes daily, displaying just how versatile steel is. For many, steel can appear as a singular material; however, it is made up of many grades, properties, and unique characteristics. Understanding the differences between each type of steel is essential when choosing the right type for your project, including how processes react with each material and where they are most effectively used.

Quick Links

Mild Steel

One of the most common types of steel is mild steel, which offers excellent formidability and reliability in performance. It has a low carbon content, which makes it a soft metal and therefore easier to cut, bend, press, weld, and engrave. In laser cutting applications, mild steel is exceptionally easy to work with, creating clean edges and repeatable results without difficulty. This is excellent for large-scale projects and helps to minimise the need for further finishes.

Due to the malleable property of the metal, it is often used during prototyping or where high-volume production is important. Although mild steel may not handle the same level of impact as other material types, it’s still a popular choice for many projects.

Mild steel is commonly applied in:

- Fabrication components

- Automotive chassis and brackets

- Fixtures in construction

- Machinery parts

- Engineering applications

Stainless Steel

Stainless steel is well known for its higher chromium content, which has excellent corrosion resistance, even in environments that have poor conditions. This makes stainless steel a favourable choice when used in industries that suffer from temperature fluctuations, higher moisture, and lower hygiene. Stainless steel is often chosen due to its visual appeal, known for its clean, bright finish, which is well-maintained when laser cut.

Different grades of stainless steel can deliver various resistance levels and strengths, such as the common 304 or the more resistant 316. Laser cutting reacts well to stainless steel across all grades, producing accurate edges and minimal heat distortion.

Stainless steel is commonly applied in:

- Food-grade equipment

- Medical devices and pharmaceutical equipment

- Architectural components and decorative features

- Marine applications

- Chemical processing equipment

Low-Alloy Steel

Low-alloy steels have a greater mechanical strength compared to the two previous steels, without adding to the overall weight of the material. This metal type is ideal for applications that need durable and structurally sound parts, and the addition of alloy elements contributes to its high-tensile strength and corrosion resistance.

Due to the higher strength of low-alloy steels, traditional machining is often prone to more wear and tear. Laser cutting removes this since it is a non-contact process, while continuing to be precise, even on tough steels. This helps preserve high turnaround times while still meeting expected project outcomes.

Low-alloy steel is commonly applied in:

- Construction frameworks

- Load-bearing components

- Transport and heavy-vehicle structures

- Agricultural machinery

- Safety-assured engineered parts

Tool Steel

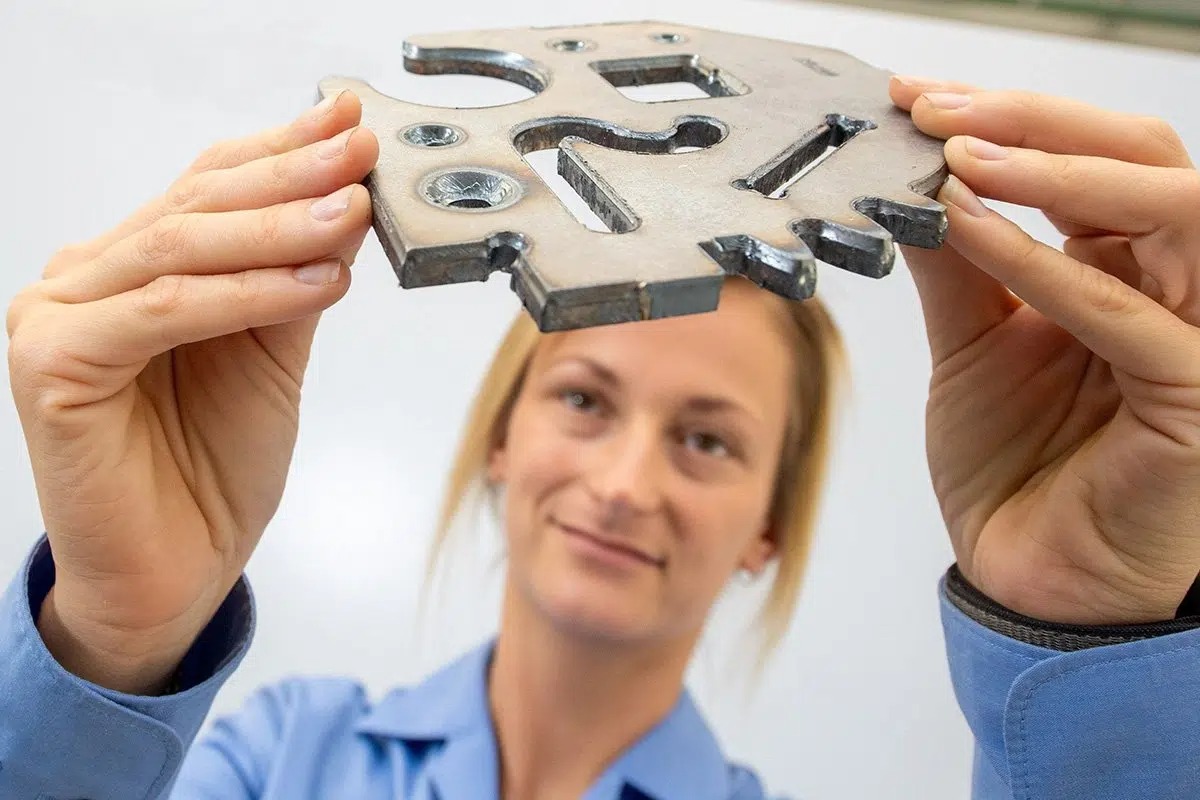

Tool steel is a super robust, heat-resistant material with exceptional hardiness, making it great in applications where it may often deal with impact or abrasion. Its high carbon and alloy levels enable it to protect its structure and performance, even under demanding conditions.

Laser cutting is highly effective at profiling tool steel, eliminating the mechanical stress from traditional contact methods. These steels may require specifically controlled methods to reduce heat-affected zones, which can be easily monitored in modern profiling. Laser cutting can deliver tight tolerances and surface finishes that minimise the need for secondary operations.

Tool steel is commonly applied in:

- Industrial cutting tools

- Dies, punches, and moulds

- Wear-resistant parts

- High-temperature components

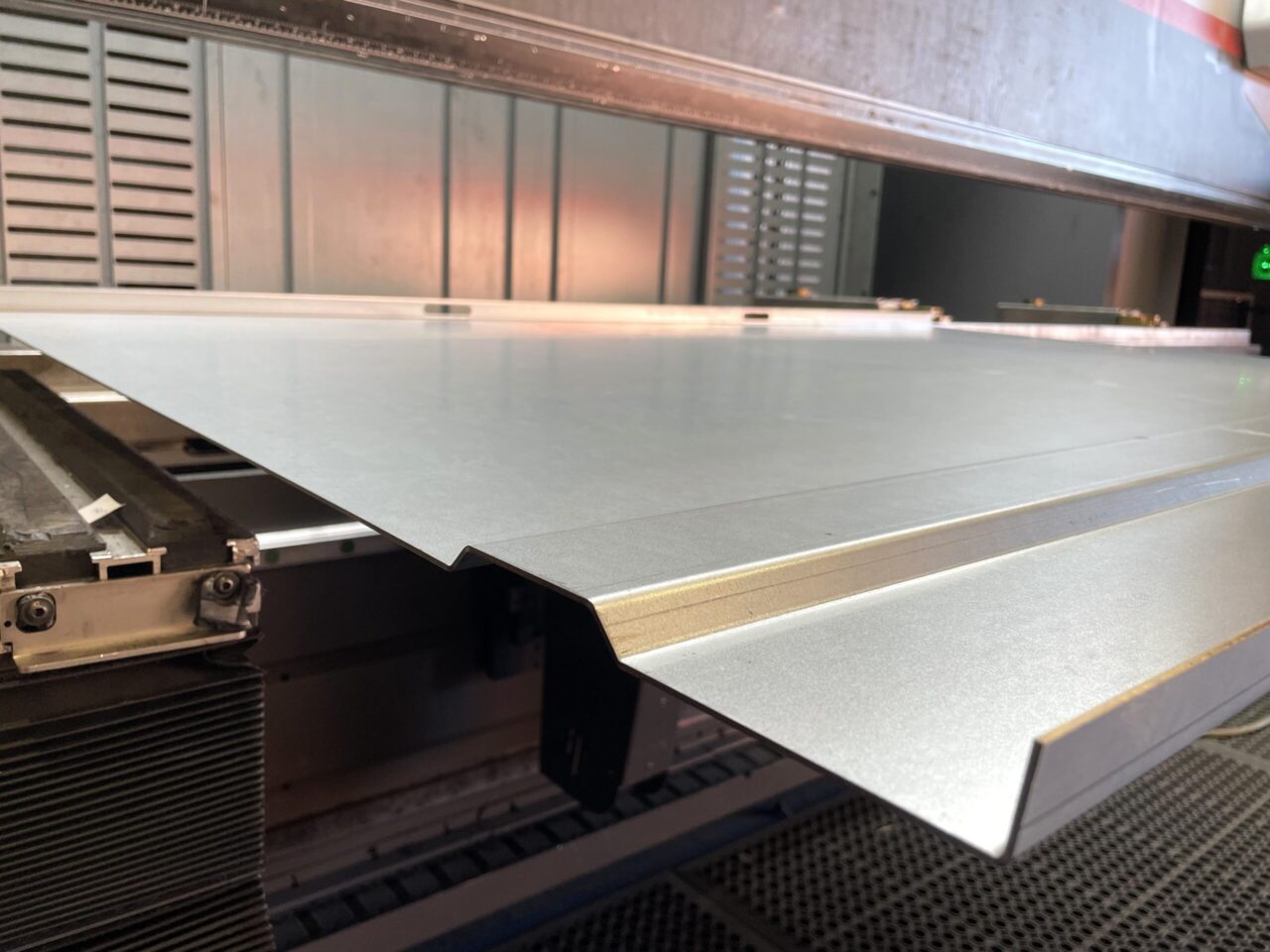

Galvanised Steel

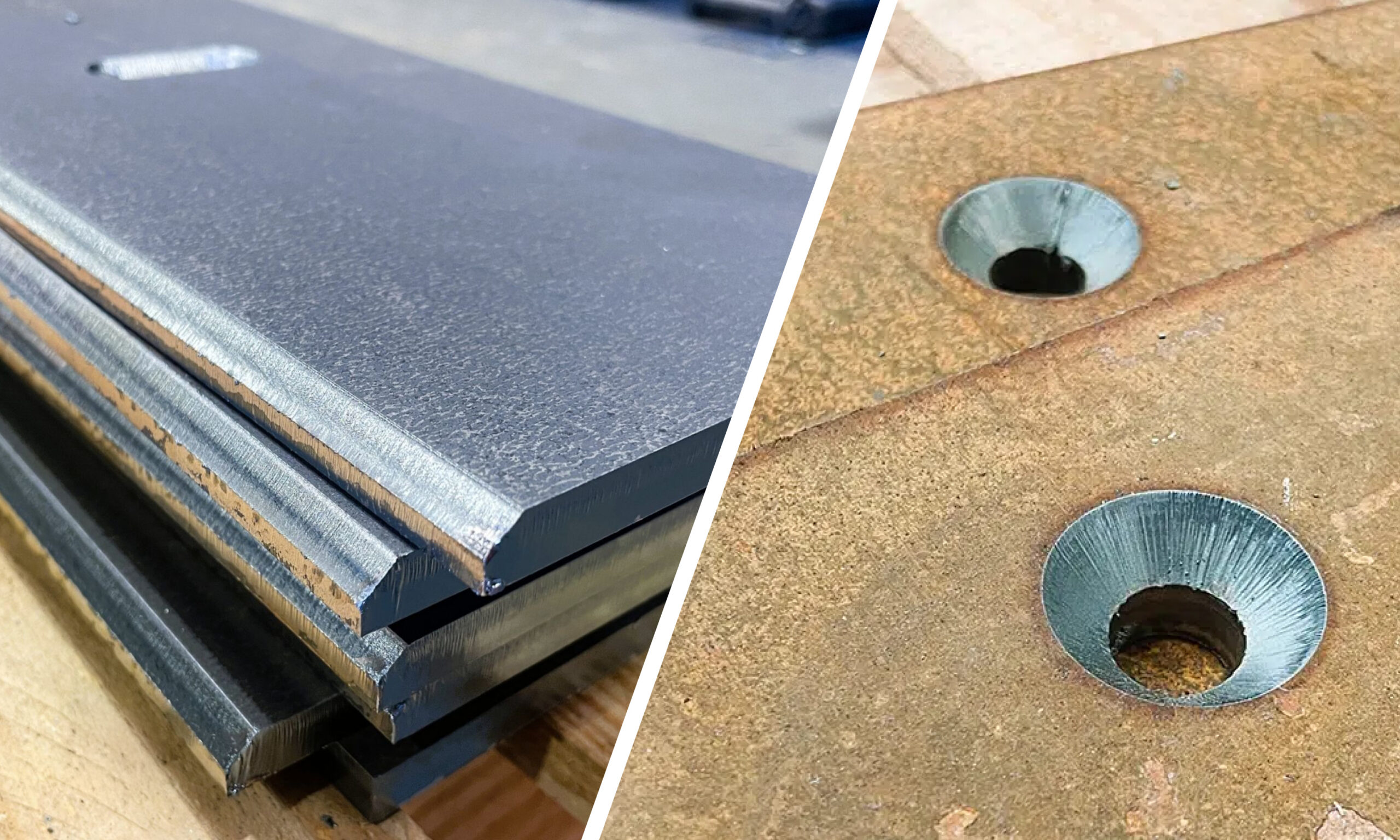

Galvanised steel benefits from a protective zinc oxide layer, ensuring it maintains excellent corrosion resistance in harsh environmental conditions. The coating helps prevent rust from forming and extends the metal’s lifespan, ideal for sectors that rely on durability and minimal maintenance.

When galvanised steel is cut, protecting the zinc coating is important. Laser cutting is highly effective at retaining the metal’s integrity due to its non-contact process, reducing distortion and preserving its protective layer, while leaving a seamless edge. This helps to make sure galvanised steel doesn’t lose its corrosion-resistant properties as it goes through the production process.

Galvanised steel is commonly applied in:

- Fencing, gates, outdoor structures

- HVAC systems

- Agricultural equipment

- Brackets and supports

- Transportation and storage units

How to Choose the Right Steel Grade for Your Application?

Choosing the correct grade of steel can set up your project for success from the start. Some factors to consider include:

Environmental

It’s important to understand how moisture, chemicals, and heat can affect the long-term performance of your component.

Strength and Durability

How much impact and abrasion will the metal be subject to?

Manufacturing Process

Heat-sensitive metals can respond better to other processes, such as waterjet cutting, which uses a powerful water stream and aggregates to cut materials.

Aesthetic Requirements

The visual finish of the metal may be a necessary feature for some projects.

Budget

It’s integral to understand how budget affects your metal choice, particularly for large-scale projects.

Achieve High Quality Cutting Across All Steel Types

At Charles Day Steels, we are proud to offer an advanced fleet of lasers that cut steel with absolute ease. Our expert team can handle various grades and material characteristics without issue, ensuring they maintain structural integrity and produce flawless results every time.

We work hand in hand with our clients to ensure quality outcomes are achieved, delivering flexible approaches to metal profiling for all projects. Irrespective of whether you’re working on large-scale production or simply want to produce prototypes, Charles Day Steels can assist you through each phase. Contact our team today to discover how our laser cutting solutions can transform your profiling needs.