Here at Charles Day Steels, we provide a plethora of laser cutting services to meet a wide range of applications and requests. With an unrivalled laser cutting capacity, unmatched cost-efficiency, and rapid turnaround, our customers receive some of the very best in laser cut pieces, parts, and projects; all completed in a timely and cost-friendly manner.

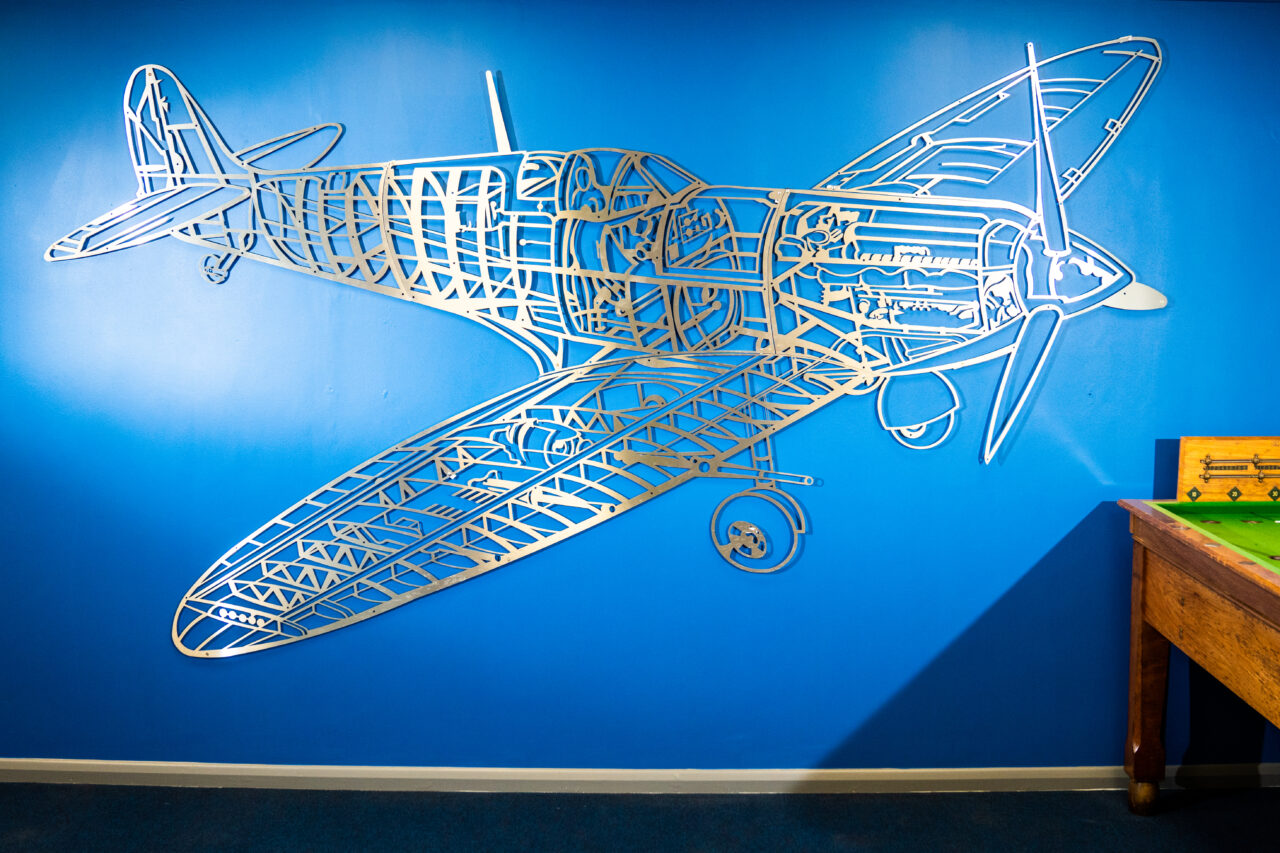

With capabilities to deliver both high volume and high complexity orders, we take immense pride in the exceptional quality of our laser cutting and metal profiling services; the very same can also be said for our completely bespoke Decorative Laser Cut Panels services.

Why Get Laser Cut Decorative Panels?

Perfect for commercial, industrial, and even residential applications, the laser cut and waterjet cut decorative panels we design, create, and supply is always completely bespoke to you, their function, and your unique requirements. Capable of cutting parts up to 6 metres long and 50mm thick, our team of industry experts utilise our state-of-the-art ByStar 15kw Fibre laser cutting machines to provide the very cleanest and most intricate cuts. Whether you’re interested in laser cut panels to divide particular areas and diffuse light into residential, office, or warehouse areas, or are looking for an imaginative way to decorate your interior or exterior walls, the versatility, and innovation brought from our decorative laser cut panels are truly endless.

Those with a more complex design can also be catered to the ability of our waterjet cutting machines. To avoid warping due to the heat involved in laser cutting, waterjet cutting can ensure even the most intricate of designs can be cut with a clean edge and zero heat-affected zones, therefore avoiding any warping of material and the requirements for any rolling or flattening of parts.

From lettering to bespoke patterns and design, with our extensive CAD and CNC technology on-site, it’s never been simpler, quicker, or more affordable to receive bespoke laser cut decorative panels and installations to suit you and your needs.

Laser Cut Panels – Applications

With a plethora of applications, our laser cut perforated metal panels are excellent for a range of premises, including commercial, residential, and industrial environments. With numerous advantages when compared to mechanical cutting, our laser cutting services offer better precision, simpler manipulation, quicker turnaround, and an overall better cut. Not only this but with less chance of damage, your laser cut panel is guaranteed to be of the very highest quality possible.

Interior Laser Cut Panels

Our bespoke laser cut decorative panels are an exceptional way to decorate and optimise your interiors. Whether you’re looking to divide your office with stylish and innovative laser cut room dividers, or even add some flair to your warehouses’ cladding and ceilings, then Charles Day’s laser cut panels are a simple, effective, and stylish solution.

Applications include €¦

- Internal Room Dividers

- Internal Wall Cladding

- Ceilings

- Art Installations

Exterior Laser Cut Panels

Not only are our laser cut panels great for interiors, but they’re also excellent for external applications too. Give your building’s exterior some extra style and elegance with custom laser cut decorative panels.

Applications include €¦

- Facades

- External Wall Cladding

- Balustrades

- Window Screens

- Art Installations

- Garden Features

Residences include €¦

- Commercial environments, i.e. bars, hotels & restaurants

- Residential environments, i.e. architecture, home & garden

- Industrial environments, i.e. warehouses & factories

Why Choose Charles Day For Laser Cut Panels

Laser cut metal panels hold a host of unique benefits depending upon their application, and are great for dividing up large work areas, diffusing light, and for their overall aesthetic appeal. Here at Charles Day, we are able to laser cut decorative panels to a range of specifications, lengths, and thicknesses. With over 40 years of direct industry experience, we understand more than most how important precision and efficiency is to you and your business, which is why year after year, we continuously re-invest in the very best and latest laser cutting technology – for the ultimate benefit of our clients.

With a suite of fully operational, state-of-the-art laser cutting machines, including the UK’s very first 20kw fibre laser cutting machine, we here at Charles Day maintain the highest levels of productivity while never compromising on cut quality.

Laser Cut Panels – Materials

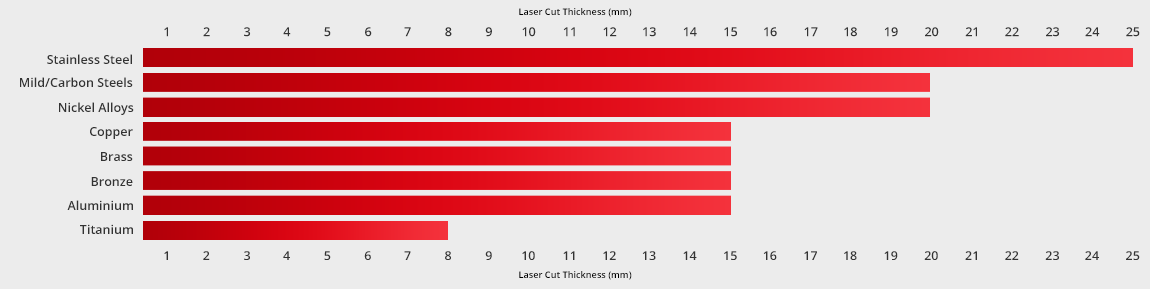

Our range of laser cutting machines are able to cut a wide variety of materials such as €¦

- Stainless Steel

- Carbon / Mild Steels

- Weathering Steel (or COR-TEN / Corten)

- Yellow Metals i.e. Copper, Brass & Bronze

- Titanium

- Aluminium

Maximum Cutting Thickness

- Steel – 50mm

- Stainless steel – 50mm

- Aluminium – 40mm

- Brass & Copper – 40mm

Some More Advantages Of Choosing Charles Day Include €¦

- State-Of-The-Art facilities

- Nationwide Delivery

- 24/7 Production

- A Selection of Polishes & Finishes To Choose From

- Range Of Panel Sizes

Contact Us For Bespoke Decorative Laser Cut Panels

If you’re interested in our range of decorative laser cut panels, then why not get in touch with the team at Charles Day for completely bespoke laser cutting services?